Archived Web Page - Draft for Public Consultation GD-360: Guidance for Life Management of Nuclear Power Plants

Archived information

Archived information is provided for reference, research or recordkeeping purposes. It is not subject to the Government of Canada Web Standards and has not been altered or updated since it was archived. Please contact us to request a format other than those available.

Preface

Nuclear power plants (NPPs) in Canada are subject to the ongoing regulatory oversight of the Canadian Nuclear Safety Commission (CNSC) to ensure that their operation does not pose unreasonable risk to health, safety, security and the environment, and conforms to Canada’s international obligations regarding the peaceful use of nuclear energy.

GD-360 contains guidance information to assist licensees in meeting the requirements of regulatory document RD-360 version 2, Life Management of Nuclear Power Plants (draft) [1] which describes the regulatory requirements for the long-term operation of an NPP and for the end of its operation.

Long-term operation of an NPP is the operation beyond the assumed design life of the plant. GD-360 provides guidance for the activities required to support the continued operation of an NPP up to its permanent shutdown and activities to support long-term operation.

The end of operation is the final, permanent shutdown of an NPP’s reactor operation. GD-360 provides guidance regarding the activities during the transition period from reactor unit shutdown and safe state of storage until the NPP enters the decommissioning phase.

Other health and safety, environmental and nuclear security considerations may dictate adherence to additional requirements. It is the responsibility of the licensee to identify any other applicable legislation or standards.

Table of Contents

2.2.2 Communication protocol for timelines and deliverables

2.2.3 Statement of licensing basis at the time of initiating the ISR

2.2.4 Safety and control area reviews

2.2.5 List of modern codes, standards and practices

2.2.6 Identification and disposition of findings

2.2.7 Risk management decision making process

2.3.2 Human performance management

2.3.8 Conventional health and safety

2.3.9 Environmental protection

2.3.10 Emergency management and fire protection

2.3.14 Packaging and transport

Appendix A: Life Management of Nuclear Power Plants

Appendix B: Technical Content Guidelines: Sufficiency Checks

1.0 Introduction

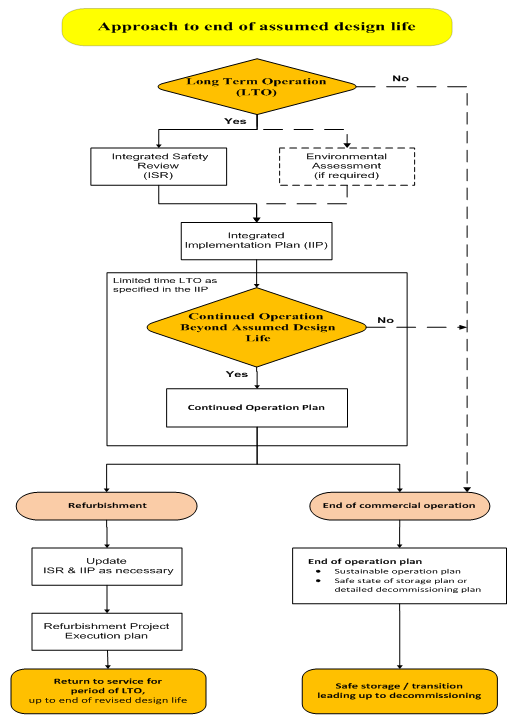

As a nuclear power plant (NPP) approaches the end of its assumed design life, the licensee implements the required steps and measures for extending or ending its operation.

Long-term operation (LTO) is the operation beyond the assumed design life of the NPP, which has been justified by the results of an integrated safety review (ISR). The licensee may decide to continue operation of the facility up to its refurbishment or permanent shutdown, or may initiate refurbishment activities to support the period of long-term operation.

End of operation is the final, permanent shut-down of reactor operation of an NPP; the NPP facility remains subject to a power reactor operating licence (PROL) that authorizes activities during the transition period from reactor unit shutdown and safe state of storage until it enters the decommissioning phase.

1.1 Purpose

This document provides guidance regarding activities a licensee must undertake to support long-term operation or to prepare for the end of operation, pursuant to RD-360 version 2, Life Management of Nuclear Power Plants.

1.2 Scope

This document covers activities to be completed during the operating phase of the NPP, under the authorization of a PROL issued by the Commission, and excludes activities that are to be undertaken under the decommissioning licence.

1.3 Relevant regulations

The provisions of the Nuclear Safety and Control Act (NSCA) and regulations made under the NSCA relevant to this guidance document are as follows:

- Subsection 24(4) of the NSCA states that “No licence may be issued, renewed, amended or replaced unless, in the opinion of the Commission, the applicant (a) is qualified to carry on the activity that the licence will authorize the licensee to carry on; and (b) will, in carrying on that activity, make adequate provision for the protection of the environment, the health and safety of persons and the maintenance of national security and measures required to implement international obligations to which Canada has agreed”

- Subsection 24(5) of the NSCA states that “A licence may contain any term or condition that the Commission considers necessary for the purposes of this Act…”

- Section 3 of the General Nuclear Safety and Control Regulations states the general licence application requirements

-

Paragraphs 12(1)(c), (f) and (i) of the

General Nuclear Safety and Control Regulations states that “Every licensee shall

(c) take all reasonable precautions to protect the environment and the health and safety of persons and to maintain security of nuclear facilities and of nuclear substances; …

(f) take all reasonable precautions to control the release of radioactive nuclear substances or hazardous substances within the site of the licensed activity and into the environment as a result of the licensed activity; …

(i) take all necessary measures to facilitate Canada’s compliance with any applicable safeguards agreement; …” -

Sections 3 and 6 of the Class I Nuclear Facilities Regulations state the general licence

application requirements specific to nuclear facilities, and the information that is required in an application

for a nuclear facility operating licence.

Other Acts, regulations, and codes are also applicable to projects to support operation beyond assumed design life. They include the Canadian Environmental Assessment Act (CEAA) [2] and associated regulations [3, 4, 5, 6 and 7] and the Canada Labour Code, Part II, Occupational Health and Safety [8]. Other relevant legislation is listed in the Additional Information section at the end of this guidance document.

1.4 National and international standards

Key principles and elements used in developing this guidance document are consistent with national and international standards, guides, and practices. The document is also consistent with:

- IAEA, Safety Reports Series No. 57, Safe Long Term Operation of Nuclear Power Plants, 2008 [9]

- IAEA, Safety Standards Series No. NS-G-2.10, Periodic Safety Review of Nuclear Power Plants - Safety Guide, 2003 [10]

2.0 Long-term Operation

Long-term operation may require the repair or refurbishment of major components, or substantial modifications to the plant, or both. The need for refurbishment will be largely dictated by the proposed period of LTO. The licensee then prepares for an integrated safety review (ISR) and the resulting integrated implementation plan (IIP). Modifications and upgrades described in the IIP for the safe operation of the facility are commensurate to the scope of the review performed and the proposed period of LTO. Once the ISR is completed and the IIP established, the licensee submits either a continued operation plan or a detailed refurbishment project execution plan including return to commercial operation considerations.

In multi-unit stations, different plans can to be applied to each unit. For example, if the licensee decides to refurbish a multi-unit station it may plan for a staggered refurbishment of each unit instead of a single continuous outage of all units at once. In this case, the plan would require considerations for both continued operation and refurbishment.

The work required in the IIP may constitute a project under the Canadian Environmental Assessment Act and be subject to an environmental assessment (EA). There is flexibility in the order in which the EA and the ISR are conducted. Information to assist the licensee in developing the project description is provided in the Canadian Environmental Assessment Agency’s publication, Preparing Project Descriptions under the Canadian Environmental Assessment Act [11].

The activities the licensee must undertake for LTO include:

- conducting the ISR

- developing the IIP

- developing and implementing the continued operation plan

- developing and implementing the refurbishment and project execution plan

2.1 Integrated safety review

The ISR is a project that includes the following activities:

- preparing the ISR basis document

- conducting the safety and control area (SCA) reviews

- performing the global assessment

- preparing the ISR final report

The results are used to establish corrective actions and safety improvements to be included in the IIP. If an extended outage for refurbishment is necessary then a refurbishment and project execution plan is also required.

The licensee should apply the principles of IAEA Safety Report No 57, Safe Long Term Operation of Nuclear Power Plants, and IAEA Safety Standard No.NS-G-2.10 Periodic Safety Review of Nuclear Power Plants, for completing the ISR for LTO.

International experience has demonstrated that licensees spend considerable time and effort to complete an ISR. The benchmark for time and effort is the conduct of a periodic safety review as described in IAEA NS-G-2.10. The licensee should plan accordingly and begin discussions with the CNSC to ensure expectations are clear and to manage project risks.

2.2 Integrated safety review basis document

The first deliverable for the ISR project is the ISR basis document, which sets out the scope and methodology for the conduct of the ISR. The basis document describes the general terms of the ISR project. To ensure the licensee and regulator have the same expectations for the scope and results of the project, the licensee should prepare and submit the basis document to the CNSC for review prior to any work on the SCA reviews.

A high level project plan should be laid out in the ISR basis document and the following should be established:

- details of project organization

- an achievable schedule highlighting major milestones

- the identification of key project members

- identification and qualifications of the contractors and vendors used

- a list of applicable outputs to the process

In some cases, the basis document will require revision. As part of the basis document, the licensee should prepare a method for proposing, tracking and documenting any changes. Additionally, guidelines on the type of changes that would require the basis document to be revised should be provided.

2.2.1 Scope

The basis document describes the scope of the reviews to be carried out as part of the ISR. To establish a common understanding of what is being reviewed, the basis document identifies facilities; structures, systems and components (SSC); and the time period covered by the review. The type of LTO (with or without refurbishment) will dictate the breadth of scope required.

The proposed period of LTO can span from a minimum of ten years, to a period comparable to the original assumed design life of the plant. When scoping the ISR, the licensee should be conservative and scope several years beyond the proposed LTO period; if the decision is made to continue operating beyond the proposed LTO period, the preparatory work is in place to identify upgrades and modifications required to continue safe operation.

2.2.2 Communication protocol for timelines and deliverables

At the outset of the ISR, an appropriate protocol should be established between the licensee and the CNSC. The licensee should provide details to address the administrative process for submissions and management of deliverables. This protocol applies to the entire project. The protocol should facilitate adherence to schedules and ensure timely submissions of complete and comprehensive information.

This protocol should facilitate meeting the requirements of all applicable regulations and RD-360, and should address the following four key items:

- identification of points of contact for communication

- specific schedules or timeframes for planned activities

- mechanism for dispute resolution

- process for controlling changes to the agreed protocol

2.2.3 Statement of licensing basis at the time of initiating the ISR

No further guidance is needed at this time.

2.2.4 Safety and control area reviews

The method that will be applied in the SCA reviews should be described in the basis document to show how the licensee plans to achieve the objectives of each SCA. The type of review (clause by clause, high-level) applied to each review element should be listed. The method of addressing interdependencies on common services and site-wide issues should also be described.

2.2.5 List of modern codes, standards and practices

An integral element of the ISR is the comparison of current plant state to modern codes and standards used in NPPs. An agreed upon code effective date and a list of codes and standards to be applied is established prior to any work being carried out. This ensures a common and consistent expectation for the reviews.

Codes and standards should be selected taking into consideration the CNSC’s regulatory framework philosophy, as well as current international practice, relevant research or new findings, any relevant operation experience, and any CNSC regulatory documents. Primary consideration for selection of standards should rest with those referenced in licenses or other regulatory documents. IAEA documents and other appropriate international standards should also be considered. If an appropriate Canadian standard is not available, the licensee should propose a reasonable substitute.

A list of common operational standards, methods and industrial best practices should be established that indicates things to be considered in the performance of the reviews.

2.2.6 Identification and disposition of findings

As the SCA reviews and global assessment are carried out, findings will be identified. The licensee should propose a method for identifying, categorizing, ranking risk, and addressing any such findings. The rationale behind the categorization of all findings should be justified by the licensee using technical arguments and supporting evidence. Priority is given to findings that do not conform to the licensing or design basis and these findings are addressed as quickly as practicable.

2.2.7 Risk management decision making process

A list of proposed corrective actions should be submitted to CNSC for acceptance. Typically, the licensee will be able to make a selection between several different methods of dispositioning findings. During the development of the corrective actions, the licensee should decide how to address and resolve the findings of the ISR.

The licensee’s process for decision making should be submitted to the CNSC for review. This process may include risk informed decision-making process, cost-benefit analysis, deterministic analysis and professional judgment. This decision-making process is applied throughout the ISR and should be clearly described in the basis document.

2.2.8 Global assessment

The global assessment is an evaluation of the overall risk associated to the NPP. To carry out the review, the licensee should use a group of non-biased specialists (i.e., people who were not directly involved in performing the SCA reviews) with sufficient expertise in the subject matter. The team should review the findings of the SCA reviews and provide an analysis of any interface issues between the SCA reviews and between any specific deviations. From this work, the licensee should be able to present an assessment of the overall risk of the NPP, including the assessment of interface issues and the risk associated with deviations identified in the ISR. The results of the global assessment should also address the extent to which the following requirements are fulfilled: safety goals and limits; defence in depth; and other fundamental safety methods.

The licensee should describe the method applied in performing the global assessment and the method used to make the risk assessments for the findings, as well as the overall risk judgment of acceptability of LTO.

If the licensee proposes to apply an accepted cost-benefit analysis approach to resolve a gap or a group of gaps, develop a corrective action, implement a safety improvement, or any combination thereof, the global assessment methodology can be used to evaluate the cost-effectiveness of the outcomes.

2.2.9 Management system applied to the ISR

The licensee should outline the management system applied in the performance of the ISR. The licensee should ensure:

- ISR review team is qualified to carry out the review

- provisions have been made for independent review of work done, both in terms of review processes and safety documentation

- data and information controls are in place to ensure that input data is used consistently across the review

- requirements for the preparation and verification of documentation are met

- results are recorded in a systematic and auditable manner; for example, when assessing against modern codes, ensure that a comparison is performed between a code and the as-built design instead of a code-to-code comparison

2.2.10 Change control

During the period between the acceptance of the ISR basis document and the start of the refurbishment activities, the codes and standards identified in the basis document may be revised or new ones may come into effect. The licensee should outline the process that will be used to address new or current revisions of codes and standards. The code effective date should be used to disposition any findings. The process should describe the methodology for assessing the safety significance of the findings.

The decision to proceed with LTO of an NPP is determined mainly by economic considerations associated with the ISR outcomes. The licensee should outline the process for communicating these changes to the CNSC. Through this process, the licensee should notify the CNSC of the change itself and of any significant implications, such as changes to the schedule, scope or processes.

2.3 Safety and control area reviews

The following sections describe the expected content of each SCA review. The licensee should carry out the SCA reviews after CNSC staff has accepted the ISR basis document. Appendix C lists the SCA and the topics to be considered for each area. Continuous improvement is an important aspect of each SCA review, so the licensee should develop initiatives for this in each review and describe the benefits to existing practices.

To ensure the reviews are consistent, the licensee should refer to Appendix B to verify that the documentation is adequately prepared and provides the required information. It is recommended that the licensee ensures that the scope of each review addresses its own requirements, and the requirements of any related SCA as applicable.

The safety and control area reviews are carried out by the licensee, who assesses the actual state of the nuclear facility against modern expectations rather than comparing old and new editions of the codes, standards and practices.

2.3.1 Management system

The review should confirm the management system’s organizational arrangements, processes, resources and plans are valid and effective to achieve the business objectives and strategies for long-term operation or end of operation, and should make adjustments as appropriate.

The review should further confirm the implementation of a management system in accordance with CSA N286 Management System Requirements for Nuclear Power Plants [13] which identifies principles and generic requirements of the management system.

Through implementation of CSA N286 and other management systems (ISO 14001 [14], OHSAS 18001 [15], etc.), the review should explore further opportunities to integrate its processes for managing the business and the actions necessary to satisfy business requirements.

2.3.1.1 Organizational performance

The organizational performance review area considers the influence that leadership, management, culture processes, and policies can have on the safety performance of licensees. This review area addresses:

- safety programs

- safety culture

- contractor management

The management system should integrate safety management into general management. Safety culture is a subset of organizational culture and can be assessed to determine the extent to which there are healthy attitudes towards risk and safety. Although safety culture itself is difficult to measure, by promoting safety culture, a licensee is able to monitor organizational health and intervene where necessary. The CNSC considers the following elements to be crucial for a strong safety culture:

- safety is a clearly recognized value of the organization

- it is clear who is accountable for safety

- safety is integral to all activities of the organization

- there is a safety leadership process

- the safety culture is learning driven

- a safety conscious work environment is evident and supported

Contractor management is included within the review area of organizational performance, as safe performance is a requirement of all workers, including contractors.

The review of the safety program and its implementation should include:

- documentation demonstrating effective application of the safety programs

- maintenance of worker competency through a systematic approach to training

The review of the program and implementation of safety culture should confirm:

- process to assess safety culture is adequate

- level of effort and expertise is appropriate

- safety culture assessments are carried out on a regular basis

- effective use of safety culture assessment results

- progress tracking

- corrective action process is effective

- disposition of actions from the CSNC before licence renewal and after major events

For contractor management, the review should confirm:

- effective prequalification and selection process

- monitoring and maintenance of staffing levels

- appropriate training for contractors

- effective work planning and integration of work by licensees and contractors

- effective supervision of contractor staff safety

- monitoring and controlling contractors hours of work

- contractor procedures that are fit for purpose

2.3.2 Human performance management

Licensees are expected to develop and implement a program that continuously monitors and improves human performance, identifies human performance weaknesses, and reduces the likelihood of human-performance related causes and root causes of nuclear safety events.

Human performance programs for a facility should be developed, reviewed for effectiveness and updated continuously, from the construction through to decommissioning of nuclear facilities.

The review should confirm that the human performance programs:

-

are a core management consideration

- are adequately resourced

- human performance is addressed for all stages of the system lifecycle, for all facility areas

-

reflect currently accepted industrial good practice

- good industry practices are followed

- lessons learned from other high hazard industries are applied as needed

- definitions of human factors and human performance are reviewed to ensure their acceptability

- address and integrate the range of human factors that influence human performance

The following elements should be reviewed to ensure there is an effective interface between them:

- provision of qualified staff

- recruitment

- certification and training

- staffing

- minimum shift complement

- fitness for duty

- hours of work

- fatigue management

- reduction of human error

- human factors in design

- procedures development

- procedural adherence

- work protection and work permit systems

- shift turnover

- pre- and post-job briefings

- organizational support for safe work activities

- human actions in safety analysis

- organizational performance and safety culture

- continuous improvement of human performance

The program should ensure that the organization supports safe work activities, and human performance information and activities are effectively integrated. The licensee should support the human performance program by ensuring the following:

- implementation by suitably qualified staff

- a common understanding of human performance

- expectations that are clearly defined, communicated and understood by all staff

2.3.2.1 Procedures

Procedures should be technically accurate, comprehensive, clear and concise, and should contain adequate information and direction for staff (for example, operators, maintainers or testers) to complete their tasks. They should be unambiguous and relevant to the current plant configuration; this ensures that procedures fit the purpose for which they are intended.

Information from task analyses should be used to develop the various technical steps in the procedure, and the format and organization of procedures are to be based on a writer’s guide that considers usability of the procedures. Procedures need to be verified for technical accuracy, and validated by a walk-through of the task(s) with representative end users, to ensure that the procedures can be carried out as intended and that the technical requirements of the tasks can be achieved.

The review of the process to develop and implement procedures should address the following:

- availability of procedures for routine, non-routine, and emergency operations

- procedures content based upon tasks, and analysis of the tasks

- competent procedure writers

- writer’s guide and usability requirements

- an effective process for the verification and validation of procedures

- an effective process for procedure review and procedural revisions

- procedures developed in a timely manner

- control of procedures documents

- training of personnel to use procedures

The review of the process for ensuring procedural compliance should include:

- clearly defined expectations of procedure use

- availability of the most up-to-date version of the procedures

- effective mechanisms for enforcing procedure use and monitoring use and deviation

- clearly defined process for managing any deviations from a procedure

2.3.2.2 Work organization and job design

Work organization and job design relates to the organization and provision of adequate staff, as well as the organization and allocation of work assigned to staff, in order to ensure that work related goals are achieved in a safe manner. G-323, Ensuring the Presence of Sufficient Qualified Staff at Class I Nuclear Facilities - Minimum Staff Complement [16] describes the CNSC’s expectations for ensuring the presence of a sufficient number of qualified staff at Class I nuclear facilities. G-278, Human Factors Verification and Validation Plans [17] describes the CNSC’s expectations for validation of adequate staffing.

The review of the work organization and provision of adequate staffing should include:

- defined and maintained staffing levels based on organizational requirements for meeting safety goals

- an auditable process in place to ensure staffing changes will not negatively impact safety goals

- an effective change management process to support staffing changes

Implementation of the process to manage the minimum shift complement should include:

- systematic analysis of facility requirements

- minimum staff complement (MSC) numbers determined for positions which may impact upon safety during an event

- validation of MSC according to G-323

- an effective plan to address MSC issues during a pandemic

- monitoring of MSC at all times

- keeping records to demonstrate that MSC is met for every shift

- reporting of MSC violations to the CNSC

- requesting consent from the CNSC for MSC changes

- periodic review of MSC program

2.3.2.3 Fitness for duty

The objective of this portion of the review is to confirm that workers who carry out tasks that could impact safety are fit for duty. An evaluation of a worker’s fitness for duty can be conducted by considering components of the program, circumstances of duty and the degree of fitness of workers. The review should describe the method used to assess the degree of worker fitness, ranging from fit to unfit, and may be classified as temporary or permanent.

In evaluating the fitness for duty program, the following components should be reviewed

- medical assessments

- psychological assessments

- hours of work

- fatigue management

- substance and biochemical assessments

The fitness for duty program should consider different circumstances of worker duty, including:

- pre-placement

- periodic

- for-cause (observed behaviour)

- post-incident

- employee assistance program

- return to work

- job transfer

- continuing disability

2.3.3 Operating performance

The licensee should have a system for keeping records of all incidents and evaluating their safety significance. In addition, records of plant operation, maintenance, testing, inspection, replacement and modifications should be regularly evaluated to identify any unsafe situations or trends. The results of these evaluations should be suitably summarized to give an overall assessment of operating performance. Performance indicators (PIs) of both failures and successes should be utilized. The ISR should review all relevant PIs, which should be subjected to trend analysis to highlight potential safety problems. The licensee can also compare the PIs with other nuclear facilities to benefit from their experiences.

Experience from other similar and dissimilar NPPs, combined with research findings, can occasionally reveal unknown safety weaknesses or can help in solving existing problems. The licensee should have arrangements for assessing information and feedback received as part of its normal activities. The SCA report should include a review of the adequacy of these arrangements and the timely implementation of any findings.

The following elements should be reviewed and verified for effectiveness:

- system for identifying and classifying safety related incidents

- arrangements for root cause analysis of incidents and feedback of results

- methods for selecting, recording, trending and providing feedback for safety related operational data, including those for maintenance, testing and inspection

- systems for formal approval, documentation and modification of procedures

- understanding and acceptance of these procedures by management and on-site staff

- evidence that these procedures are followed

- degree of reliability of assumptions made with respect to licensee actions and findings of the safety analysis, plant design and operating experience

- arrangements for the feedback of experience relevant to safety from similar or other plants

- arrangements for the receipt of information on the findings of relevant research programs

- assessments of -and actions on-the research information

- plant modifications resulting from operating experience and research information gained

2.3.3.1 Performance monitoring and improvement

Performance monitoring and improvement is the process of gathering data and information about the performance of an organization’s activities, analyzing the data, developing and implementing improvement plans, and monitoring the effectiveness of changes intended to bring about the improvements.

Human actions either cause or contribute to majority of events so event analysis should include identification of such causes and contributing factors. This information should be used to make changes to reduce the likelihood of these events occurring in the future.

The following processes should be reviewed and verified for effectiveness:

- identify and record plant conditions

- process to conduct internal performance assessments

- benchmarking activities and their results

- corrective action

- periodic audits

2.3.4 Safety analysis

2.3.4.1 Deterministic safety analysis

The SCA review should update the current safety analysis as necessary to ensure that it is based on the actual plant design, reflects the current state and predicted state of SSC at the end of the review period, and considers all postulated initiating events that are appropriate for the plant design and plant location.

Current, accepted and analytical methods should be used, particularly with regard to computer codes for transient analyses. The assumptions used in these calculations (conservative or best estimate) should be justified with respect to the inherent uncertainties in order to gain greater insight into existing safety margins.

The following elements should be reviewed:

- existing deterministic safety analyses and their assumptions

- limits and permitted operational states

- anticipated operational occurrences

- postulated initiating events (for the existing safety analyses and a comparable list for a modern nuclear facility)

- analytical methods and computer codes used in the existing deterministic safety analyses and comparable methods for a modern nuclear facility, including validation

- radiation doses and limits on radioactive releases for accident conditions

- guidelines for deterministic safety analyses, including guidelines for single failure criterion, redundancy, diversity and separation

The review of the deterministic safety analysis should determine whether the actual plant design is capable of meeting the prescribed regulatory limits for radiation doses and radioactive releases resulting from postulated accidents. It should also identify or confirm any major weaknesses or strengths of the plant design in relation to the application of defence in depth, and should evaluate the importance of systems and measures to prevent or control accidents, with a complete set of postulated initiating events taken into account.

If the safety concept of the plant design differs from current practice, any advantages or disadvantages inherent in that safety concept should be addressed.

The current state of this safety analysis should be reviewed for completeness of the set of postulated initiating events and for its scope, methods and assumptions.

2.3.4.2 Probabilistic safety analysis

The SCA review should update the probabilistic safety analysis (PSA) as necessary to ensure it is valid as a representative model of the plant when the following aspects are taken into account: changes in the design and operation of the plant; new technical information; current methods; and new operational data.

The PSA should include a human reliability assessment (HRA). HRA is a method of estimating the probability of human errors in terms of the probability that a system-required human action, task or job required for safety will not be completed successfully within a required time period. HRA can also consider the probability that extraneous tasks or actions detrimental to system reliability or availability will be performed.

The results of a PSA should be compared with the probabilistic safety criteria (for example for system reliability, core damage and releases of radioactive material) when they have been defined for the facility.

The PSA should be kept sufficiently up to date during the plant lifetime to make it useful in the decision-making process. The PSA should be used to identify opportunities for future improvements by revealing weaknesses in the plant design and operation.

The accident management program for beyond design basis accidents should be reviewed. It should be determined whether the program is suitable for preventing severe core damage or to mitigating its consequences.

The following should be addressed in the review:

- existing PSA and its assumptions

- updating of the PSA to reflect current facility status

- postulated initiating events (for the existing PSA and a comparable list for a modern nuclear facility)

- analytical methods and computer codes used in the existing PSA and comparable methods for a modern nuclear facility, including validation

- guidelines for the PSA of operator action, common cause events, cross-link effects, redundancy and diversity

- consistency of the accident management program for beyond design basis accidents with PSA results

2.3.4.3 Hazard analysis

The review should confirm adequate protection of the NPP against internal and external hazards and should consider the actual plant design, site characteristics, condition of SSC and their predicted state at the end of the period covered by the PSA, and current analytical methods, safety standards and knowledge. The review should establish a list of internal and external hazards that could affect plant safety, taking into account plant design, the condition of SSC and site characteristics. The licensee should also consider changes in plant design, climate, flood potential, and transport and industrial activities near the facility site.

The following analyses should be addressed:

internal hazards such as fire (prevention and suppression), flooding, pipe whip, missiles, steam release, spray, toxic gas, explosion and crane movements

external hazards such as changes in site characteristics, flooding and tsunami, high winds, temperature extremes, seismic hazards, aircraft crash, toxic gas and explosion

for relevant hazards, the review should use current analytical techniques and data to demonstrate either that the probability or consequences of the hazard are sufficiently low so no specific protective measures are necessary, or that the preventive and mitigating measures against the hazard are adequate; any deficiencies should be identified

2.3.4.4 Human factors in safety analysis

The licensee should examine the contribution of human error and human reliability in identifying hazards and risks, and also consider human actions during normal and accident conditions in operability studies, failure modes, and effects and hazard analyses.

Industry best practice should be followed in the assessment, analysis and modeling of human actions. Factors that impact on human performance (human factors) should be considered, and validation of human actions should be conducted to ensure that they are achievable. Human actions should be considered consistently across different safety analyses and in system design activities.

The review of human factors in safety analysis should include:

- systematic method of task analysis and human error identification

- integration of human errors within the safety analysis

- robust, proven, and systematic human error quantification method

- documentation of the analysis

- appropriate representation of human errors in the safety analysis according to risk

- consideration of limitations of methods and techniques

2.3.5 Physical design

The objective of the review of the design of the nuclear power plant is to determine the adequacy of the design and its documentation in an assessment against current international standards and practices.

The review of the plant design should confirm the list of SSC that can directly or indirectly have an adverse effect on the safe operation of the NPP is complete and comprehensive. The review of the plant design should be subdivided into review topics by systems and/or subject matter areas, such as:

- reactor core

- shutdown systems

- primary coolant system

- secondary systems

- containment system

- emergency heat removal, instrumentation and control systems

- electrical power systems

- water supply systems

- fire protection

- human factors in design

- protection against postulated pipe rupture.

The review of the plant design should identify the differences in plant design in an assessment against current safety standards (including relevant design codes) and determine their safety significance (strengths or weaknesses) in relation to the application of defence in depth. The licensee should ensure that the plant configurations and conditions assumed in the safety case reflect the actual plant state. Adequate design information, including information on the design basis, should be available to provide for the safe operation and maintenance of the plant and to facilitate plant modifications.

The SCA review for plant design should include:

- detailed description of the plant design, supported by drawings of the layout, system and equipment

- list of SSC that can, directly or indirectly, have an adverse effect on the safe operation of the NPP and their safety classification

- documented design basis (original and updated)

- significant differences (strengths and weaknesses) between the present plant design and the modern standards and practices (used for comparison)

- safety significance of the identified findings relating to the application of defence in depth

For some older plants, documentation relating to the safety of the design basis will not have been supplied in full to the operator at the commissioning stage. The SCA report should ensure that all significant documentation relating to the original design basis has been obtained, securely stored, and updated to reflect all the modifications made to the plant and procedures since its commissioning.

2.3.5.1 Human factors in design

Human factors (HF) are factors that influence human performance as it relates to the safety of a nuclear facility or activity over all phases, including design, operation, maintenance, and decommissioning. Factors may include the characteristics of the person, task, equipment, organization, environment, and training. It encompasses overall facility layout and design (for example, access and the physical working environment), the design of the workstations and work areas both in control areas and field locations, and the design of specific human-machine interfaces that have the potential to impact safety (for example, control panels, computer-based displays, alarms, and tools).

The licensee should consider any changes made to the design of facilities, systems, or equipment, and then ensure that the impact upon other areas such as training and procedures is determined and addressed. There should be a systematic process for effectively incorporating human factors considerations into system requirements, definition, analysis, design, verification, and validation activities. This process should be carried out by suitably trained, and qualified, specialists.

The review of human factors in design should confirm:

- timely HF inputs as required

- appropriate level of HF effort and expertise

- use of applicable modern codes and standards

- systematically addressing human factors for all plant areas, for all operational scenarios throughout the lifecycle of the plant/system

- verification and validation of human factors and human performance aspects

- appropriate documentation for planning, analysis, verification and validation, and integration into design documentation

G-276, Human Factors Engineering Program Plans [18] and G-278, Human Factors Verification and Validation Plans describe CNSC staff’s expectations of human factors engineering program plans and human factors verification and validation plans, for Class I nuclear facilities and uranium mines and mills, respectively. Expectations for human factors in long-term operation projects are contained in RD-337, Design of New Nuclear Power Plants [19].

2.3.6 Fitness for service

2.3.6.1 Actual condition of SSC

The licensee must determine the actual condition of the SSC of the NPP, including any existing or anticipated obsolescence of plant systems and equipment. This determination should be made at an early stage of the ISR and should then be updated periodically throughout the service life of the NPP or SSC. The process used in carrying out condition assessment of SSC should be documented prior to the start of work. These include, but are not necessarily limited to:

- listing all known and identifying any potential aging degradation processes which could act upon the SSC

- identifying the cause and extent of the degradation on the SSC

- evaluating the current and predicted future effect of the degradation on the functional and performance requirements of the SSC

- identifying means to mitigate aging mechanisms and their effects, such as repairing the SSC to satisfactory condition and preventing further deterioration of the SSC

- providing more frequent inspections of the SSC

- replacing the SSC

- no active intervention

- evaluating the effectiveness of mitigating measures currently in place

- providing recommendations for improvements to existing programs in order to better manage the aging degradation of SSC, including justification for the chosen approach

Existing records should be checked to ensure that they accurately represent the actual condition of the SSC, including any significant findings from ongoing maintenance and inspections. It may not be possible to determine the actual condition of some areas of the plant, owing, for example, to plant layout or operating conditions that preclude a necessary inspection. Such areas should be highlighted and their safety significance considered.

The review of the actual condition assessment of SSC should include:

- a list of SSC that can, directly or indirectly, have an adverse effect on the safe operation of the NPP and their safety classification

- information about the integrity and functional capability of SSC important to safety, including material case histories

- information on the existing or anticipated obsolescence of any SSC important to safety

- findings of tests that demonstrate the functional capability

- results of inspections

- maintenance records

- description of the present condition of SSC important to safety

- description of the support plants available to the plant both on and off the site, including maintenance and repair shops

Having determined the current condition of the SSC important to safety, each of the SSC should then be assessed against its design basis to confirm that aging has not significantly undermined the design basis assumptions. Where consistency with the design basis cannot be fully demonstrated, alternative arrangements should be made to show that the SSC is fit for its purpose and safety margins remain adequate until the end of the proposed LTO, or proposals should be made for corrective actions. This may include additional inspections or, in some cases, component replacements. It may be necessary to use the safety analysis to determine any revised duties or loadings on SSC during normal operation and under accident conditions.

The results of the review of actual condition of SSC should provide information on:

- the current performance and condition of the SSC, including assessment of any aging related failures or indications of significant material degradation, previously unidentified aging mechanisms or effects, and comparisons against predictions for the aging mechanisms and acceptance criteria

- estimation of future performance, aging degradation, and residual service life, where feasible, of the SSC (i.e., the length of time the SSC is likely to meet its function and performance requirements)

- the effectiveness of the aging management programs (AMP) in place for future plant operation

- recommended follow-up or prevention, monitoring, and mitigation measures to be completed and/or incorporated into the AMP, including appropriate intervals for follow-on condition assessments and areas for further research and development

Where measured data is unavailable, the assessment of an SSC should be based on its safety significance and derived from other reliable resources, such as industry reports and special tests or inspections.

2.3.6.2 Equipment qualification

Plant equipment important to safety should be properly qualified to ensure its capability to perform its safety functions under postulated service conditions, including those arising from internal and external events and accidents (such as loss of coolant accidents, high energy line breaks, seismic or other vibration conditions, flooding, fires) in a manner consistent with the safety classification. A qualification procedure should be used to confirm that the equipment is capable of meeting, throughout its service life, the requirements for performing safety functions while subject to the environmental conditions (vibration, temperature, pressure, jet impingement, irradiation, corrosive atmosphere and humidity) prevailing at the time of need, with the aging degradation of the equipment that occurs during service taken into account.

Qualification of plant equipment important to safety should be achieved through a process that includes generating, documenting, and maintaining evidence that equipment can perform its safety functions during its installed service life. This should be an ongoing process, from the plant design to the end of service life; plant aging, modifications, repairs and refurbishment, equipment failures and replacements, and abnormal operating conditions should be taken into account.

Although many parties (such as plant designers, equipment manufacturers, and consultants) are involved in the equipment qualification process, the licensee has the ultimate responsibility for the development and implementation of a plant specific equipment qualification program that includes generating and maintaining the documentation demonstrating qualification.

The review of equipment qualification should include:

- list of equipment covered by the equipment qualification program and a list of control procedure

- qualification report and other supporting documents (for example equipment qualification specifications and qualification plan)

- verification that the installed equipment matches the qualified equipment

- procedures to maintain qualification throughout the installed service life of the equipment

- mechanisms for ensuring compliance with these procedures

- a surveillance program and a feedback procedure to ensure that aging degradation of qualified equipment remains insignificant

- monitoring of actual environmental conditions and identification of ‘hot spots’ of high activity

- analysis of the effects of equipment failures on equipment qualification and appropriate corrective actions and/or safety improvements to maintain equipment qualification

- protection of qualified equipment from adverse environmental conditions

- physical condition and functionality of qualified equipment (to be confirmed by walk downs)

- records of all qualification measures taken during the installed service life of the equipment

The review of equipment qualification should determine: (a) whether assurance of the required equipment performance capability was initially provided and (b) whether equipment performance has been preserved by ongoing application of measures such as scheduled maintenance, testing, and calibration, and has been clearly documented. It should be noted that a review relating to (a) above may not be necessary if a previous review has concluded that adequate initial equipment qualification was established and a review relating to (b) above should provide assurance that equipment qualification will be satisfactorily preserved in future. A plant walk down of installed equipment should be performed to identify for qualified equipment any differences from the qualified configuration (abnormal conditions such as missing or loose bolts and covers, exposed wiring, or damaged flexible conduits).

2.3.6.3 Aging management

All SSC of nuclear plants are subject to some form of physical changes caused by aging, which can eventually impair their safety function and service lifetime. The rates of these changes vary considerably. Special attention should be paid to cases of prolonged construction and extended shutdown. Aging of all materials (including consumables, such as lubricants) and SSC that could impair their safety functions should be understood and controlled. Managing aging for nuclear power plants means ensuring the availability of required safety functions throughout the service life of the plant (including period of LTO), with account taken of changes that occur with time and use.

Whereas the review of the actual condition of the SSC establishes the condition of the SSC at the time of the ISR, the SCA aging management is primarily concerned with the programs and arrangements in place to ensure condition of the SSC in the future. The SCA review of aging management should be conducted in accordance with RD-334, Aging Management of Nuclear Power Plants [20] and IAEA Safety Report Series No. 57 Safe Long Term Operation of Nuclear Power Plants. It should determine whether a systematic and integrated aging management program framework is in place and effective, whether adequate arrangements have been made to fulfill required safety functions during future plant operation, and whether there are any features that would limit plant life. Both programmatic aspects (for example, procedures, performance indicators, staffing) and technical aspects of aging management (for example, understanding of relevant aging phenomena, SSC specific acceptance criteria, aging detection and mitigation methods) should be evaluated.

The review of aging management should confirm a systematic and comprehensive aging management program framework is in place for the facility. It should also demonstrate:

- all SSC that can, directly or indirectly, have an adverse effect on the safe operation of the NPP are covered by the aging management program

- all SSC that can affect safety are evaluated for the proposed period of LTO

- all significant aging mechanisms have been identified, and there is a thorough understanding of the relevant aging mechanisms and their effects

- models used to predict the evolution and advancement of degradation are supported in accordance with current accepted practices pertaining to age related degradation

- SSC-specific or aging mechanism-specific aging management programs are evaluated against defined attributes and shown to be effective

all safety analyses involving time limited assumptions are validated for the proposed period of long term operation to ensure that the aging effects will be effectively managed (i.e., to demonstrate that the intended function of an SSC will remain within the design safety margins throughout the planned period of long term operation)

The SCA report on aging management should include:

- program policy, organization and resources for aging management

- documented method and criteria for identifying SSC covered by the aging management program

- list of SSC covered by the aging management program and records that provide information in support of the management of aging

- evaluation and documentation of potential aging degradation that may affect the safety functions of SSC

- extent of understanding of dominant aging mechanisms of SSC

- availability of data for assessing aging degradation, including baseline, operating and maintenance history

- effectiveness of operational and maintenance programs in managing aging of replaceable components

- programs for timely detection and mitigation of aging mechanisms and/or aging effects

- acceptance criteria and required safety margins for SSC

- awareness of physical condition of SSC, including actual safety margins, and any features that would limit service life

- the results of the review of aging management to demonstrate that aging effects will continue to be identified and managed for these SSC during the planned period of LTO

2.3.7 Radiation protection

The review of radiation protection should demonstrate:

- the extent that radiation protection has been accounted for in the design and operation of the NPP

- the extent that the operating organization has integrated its radiation protection (RP) program requirements into its management system

- whether the RP program provides adequate protection of workers and the public

The licensee should identify all sources of exposure and evaluate radiation doses that could be received by workers as a result of the operation of the plant. The licensee should provide the information on the design and operational arrangements that have been made to minimize the number and locations of radiation sources and the radiation fields associated with them. A review should be included that identifies areas of high activity and their impact on the safety of the plant and site personnel.

The licensee should demonstrate the design and layout of the reactor facility meets CNSC regulatory expectations for radiation protection as set out in, RD-337 Design of New Nuclear Power Plants and RD/GD-369 Licence Application Guide: Licence to Construct a Nuclear Power Plant.

The review of the RP equipment and instrumentation should confirm that there is adequate radiation monitoring in operational states and accident conditions and, as practicable, beyond design basis accidents. The licensee should review the physical condition of radiation instrumentation and equipment and the NPP’s dependency on obsolescent radiation protection equipment for which no direct substitute is available.

2.3.7.1 Radiation protection program

The licensee should evaluate the following aspects of the RP program:

- aging of all materials and obsolescence of the technology of SSC that could impair their radiological safety functions

- classification of areas and access control, including local rules and information on actual dose rates and contamination levels

- radiation exposure and dose control

- co-operation in establishing operating and maintenance procedures when radiological hazards are anticipated, and providing direct assistance when required

- radiation personal protective equipment

- on-site radiological monitoring and surveys

- personnel dosimetry / dose assessment

- radioactive contamination control

- decontamination of personnel, equipment and structures

- solid radioactive waste and radioactive shipments (or control of dispatch of radioactive materials, including transfers and disposal of solid radioactive waste)

The review of the radiation protection program should confirm that radiation protection requirements are implemented by addressing the generic management system principles in Section 3.3.1 Management System, as they relate to radiation protection, by following relevant national and international standards and guidance, and by good industry practice. The licensee should review the arrangements for each controlled area in response to accidents and malfunctions, to include access to PPE, instrumentation and equipment.

The review should confirm the NPP has an appropriate process for the routine recording and evaluation of safety related operating experience, including:

- radiation protection related incidents, or events and near misses

- replacements of RP equipment due to failures or obsolescence

- radiation doses (to workers, including contractors)

- on-site contamination and radiation levels

- generation of radioactive waste

- compliance with regulatory requirements

Records of radiation doses should be reviewed to determine whether these are within prescribed limits and adequately managed. Although radiation risks need to be considered generically across the ISR, the review of this SCA should specifically consider data on radiation doses and the effectiveness of radiation protection measures. The review of radiation doses needs to consider the types of activity being undertaken. This will provide an indication of the risk posed to plant personnel.

2.3.8 Conventional health and safety

Conventional health and safety influences all aspects of safety in an NPP. The review should establish confidence that there is a safe work environment and examine the status of occupational safety within the plant to determine whether or not the licensee complies with accepted good practices and whether there is any unreasonable contribution to risk from non-radiological hazards. Hazardous waste management is addressed in this review, including the licensee’s control practices.

The following elements should be included in the review:

- oversight of the occupational health and safety program

- housekeeping practices and any related procedures

- the condition and availability of emergency response equipment

- policy and procedure for the identification of hazards (for example, mechanical, chemical) and verification that the procedure is applied

- programs and procedures related to the segregation and containment of hazardous materials

- description of licensee activity for maintenance, availability and use of personal protective equipment

- assurance of compliance as related to applicable labour, building and fire codes

2.3.9 Environmental protection

The scope of the environmental protection review includes programs that identify, control, and monitor all releases of radioactive and hazardous substances, and the effects on the environment from the facility’s licensed activities. In addition, it also includes effluent and environmental monitoring; estimation of the dose to members of the public; radioactive waste management; hazardous waste management; response to unplanned releases; and assessment of environmental protection compliance with regulatory requirements including the environmental elements of the management system.

The following elements should be included in the review:

- the management system policy, programs and procedures that address environmental protection requirements

- the program to determine the environmental baseline characteristics of the site and the surrounding area

- assessment of potential sources of environmental impacts

- characterization of discharges of radioactive and hazardous substances

-

effluent and environmental monitoring program which includes :

- locations of points of release

- maximum quantities and concentrations

- anticipated volume and flow rate of releases of nuclear substances and hazardous substances into the environment, including their physical, chemical and radiological characteristics

- environmental monitoring program for the nuclear and hazardous substance waste management

- measures to control releases of nuclear substances and hazardous substances into the environment

- estimated dose to members of the public

- management system elements for the environmental monitoring program

- measures to comply with dose limits for the public and the implementation of ALARA in the environmental protection program

- evaluation of preventive and control measures

- the positions for, and qualifications, training, and responsibilities of workers responsible for environmental protection

- communication and reporting of the environmental monitoring program results

- proposed program to inform persons living in the vicinity of the site of the general nature and characteristics of the anticipated effects on the environment and the health and safety of persons that may result from the licensed activity

- alarm systems to respond to unplanned releases of effluents from on-site facilities

- measures to identify changes in the use of areas around the site

2.3.10 Emergency management and fire protection

The design and operation of a nuclear power plant should ensure that the release of substances affecting the health of workers and the public are minimized to the extent practicable. Planning for the possibility of such releases is a necessary action, not only by the licensee, but also by local, provincial and national authorities.

The licensee should perform an overall review to verify that the emergency planning at the plant continues to be satisfactory. Emergency plans should be maintained in accordance with current safety analyses, accident mitigation studies, and good practices. Emergency exercises should demonstrate and identify possible gaps in the training of on and off site staff, the required functional capability of equipment (including communication equipment) and the adequacy of planning.

The review should confirm that consideration has been given to significant changes at the nuclear plant site, and in its use, such as organizational changes and changes in the maintenance and storage of emergency equipment, and of industrial, commercial and residential developments around the site.

The following elements should be addressed:

- studies of the mitigation of accident consequences

- strategy and organization for emergencies

- documentation of the emergency plans

- plans and procedures for emergencies

- on-site equipment and facilities for emergencies

- on-site emergency centres

- communications

- emergency training, exercises and records of experience

- interactions of relevant organizations such as the regulatory body, police, fire departments, hospitals, ambulance services, local authorities, public welfare authorities and the information media

- arrangements for regular reviews of emergency plans and procedures

- security arrangements for emergencies

2.3.11 Waste management

The licensee should put in place a waste management plan and a system for keeping a record of all issues related to radioactive waste management. Records of waste quantities, storage, inspections, and transfers should be regularly documented in order to identify any unsafe situations or trends. The results of these records should be suitably summarized to give an overall assessment of the management of radioactive waste during each year of plant operation.

The strategy for managing all wastes should be described in the waste management plan, covering both the short term and where possible, the long term. A waste management plan should include:

- descriptions of the area, procedures, criteria, and instruments that will be used to monitor and segregate wastes into different categories

- estimation of the quantity of waste in each category

- specific plans for reuse, recycle, storage, or disposition of the wastes

- clearance levels for the release of material or equipment

- to the extent possible, a long-term waste management strategy

- cost-benefit analysis

The procedures for the management of waste resulting from normal operations are also important factors. Relevant information on the procedures for the waste management processes should cover classification, minimization, segregation, clearance, handling, volume reduction, treatment, packaging, storage, transportation, and final disposition.

The following elements should be addressed and verified:

- the contents of a waste management plan and waste management processes

- a system for monitoring and classifying waste safety related incidents

- arrangements for analysis of waste safety related incidents

2.3.12 Security

The annual site security plan, prepared and submitted by the licensee, encompasses key areas for review in support of the security safety factor. These areas are verified through the review of security performance via promotion, inspection, and verification activities of the nuclear facility. These activities are conducted in conjunction with performance indicators that are used to assess security performance of a facility, for example, CNSC regulatory documents and guides:

- RD-321, Criteria for Physical Protection Systems and Devices at High-Security Sites (confidential document) [21]

- RD-361, Criteria for Explosive Substance Detection, X-ray Imaging, and Metal Detection Devices at High-Security Sites (confidential document) [22]

- RD-363, Nuclear Security Officer Medical, Physical, and Psychological Fitness [23]

- G-208, Transportation Security Plans for Category I, II or III Nuclear Material [24]

- G-274, Security Programs for Category I or II Nuclear Material or Certain Nuclear Facilities [25]

In addition, the review should confirm the accuracy and completeness of documentation of the facility’s site security plan. CNSC expectations are that the nuclear facility will assess the extent to which it meets the security goals and requirements, address all gaps identified, and provide a clear justification for any exemptions, including any associated with their waste management plants or areas.

The review should include the following elements:

- general security information relating to facility location, applicant’s security policy, legal name, address, contact personnel, and associated telephone numbers

- security organization relating to roles within the facility organization, structure and organization of the nuclear security officer/ nuclear response force service, selection criteria for nuclear security officers/ nuclear response force training, exercises, drills, equipment and vehicles for nuclear security officers/ nuclear response force, and records for the above

- protected and inner areas

- security monitoring room(s), and on-site and off-site communications equipment, systems and procedures

- access and identification systems including the control of identification badges or access cards and use of identification badges or access cards

- access controls including screening for weapons and explosive substances (on entry to a protected area) and screening for Category I, II, and III nuclear material (on exit) from a protected area for vehicles, persons, packages/equipment and access devices and access to information

- security systems, technical devices and equipment

- design and performance characteristics

- maintenance, testing and inspection programs

- contingency plans and procedures

- availability and duties of nuclear security officers/nuclear response force members

- sabotage or attempted acts of theft or sabotage of nuclear material or prescribed information/equipment

- protection arrangements with off-site response forces

- security awareness program

- written commitment to maintain and/or replace aging or obsolete equipment and the licensee’s record of equipment maintenance and replacement

2.3.13 Safeguards

CNSC’s regulatory mandate includes ensuring conformity with measures required to implement Canada’s international obligations under the Treaty on the Non-Proliferation of Nuclear Weapons. Pursuant to the Treaty, Canada has entered into a safeguards agreement with the IAEA. This agreement provides the IAEA with the right and the responsibility to verify that Canada is fulfilling its international commitment on the peaceful use of nuclear energy.

CNSC provides the mechanism for the IAEA to implement the safeguards agreement through the NSCA, and its regulations and facility licences. Essential requirements for the application of IAEA safeguards are stated as specific licence conditions.

The essential requirements on the facility to ensure Canada can continue to meet its international safeguards obligations include:

- timely and accurate provision of reports on nuclear materials

- provision of access and assistance to IAEA inspectors for verification activities

- submission of annual operational information and accurate design information of plant structures, processes and procedures

- development and satisfactory implementation of appropriate facility safeguards procedures

The safeguards review should verify:

- an approved safeguards program is established by the facility to identify safeguards-related responsibilities and to provide appropriate documentation and resources in support of CNSC regulatory requirements

- approved operating procedures provide detailed information on defined operator activities for safeguards implementation at the facility

- all necessary safeguards measures are in place to facilitate compliance with the NSCA and the CNSC’s regulatory documents and licence conditions

- a system of nuclear material accountancy and reporting is established according to CNSC requirements

- the facility has provided, in a timely manner, all required reporting on safeguards related operational information and on design information for plant structures and nuclear material

2.3.14 Packaging and transport

The review should focus on the regulatory requirements as they relate to the transport activities performed. The regulatory requirements should be used as criteria for evaluation purposes for each review element.

The following elements should be reviewed:

- training: the program should state what training is required in relation to the duties to be performed

- packaging: the program should cover the package selection, certification of packages, registration of packages, maintenance, and use

- documentation: the program should incorporate a section on the shipment documentation to be used for the transportation of radioactive materials

- dangerous safety marks: the program should describe how and which dangerous goods safety marks are to be displayed on packages and vehicles

- handling: the program should state how non-fixed contamination of external surfaces of packages and on vehicles is controlled

- reporting requirements: the program should state how dangerous occurrences are reported

- records: the program should include the records keeping requirements for the various sections

2.3.15 Safety and control area reports

The SCA reports contain the licensee’s results for the specific review topics in each SCA. The results of the conformity reviews and the comparison against modern codes, standards, and practices are also included. Any findings are categorized and dispositioned in accordance with the process indicated in section 3.2.5.

Each SCA report is expected to contain a number of standard elements. The overall structure of each report should be: a summary of the review followed by detailed reporting and conclusions. The report should include:

- a statement of the objectives of the review

- description of the scope of the review covered in the report

- clear indication of the type of review conducted: a clause-by-clause review, a high-level review, or a combination thereof, and the rationale for selecting this type of review

- systematic coverage of the expected review elements with detailed analysis of how the licensee addressed expectations to fulfill design and licensing bases, as well as satisfying modern codes and standards set out in the basis document

- supporting figures, tables, graphs, data, and any other design or operational information that would be used to support the licensees arguments

- clear indication of the licensee endorsement of any work done by an outsourced contractor, and whether the licensee has corrected any statements made by the contractor

- enough information to allow CNSC staff to make a regulatory determination based on the information contained in the report, which means that the SCA report must be self-standing and complete

SCA reports should not contain: unsupported personal opinion, conjecture, or claims; the names of any individuals; or criticisms of internal processes, procedures.

The licensee should prepare the ISR safety and control area reports to be as self-contained as practicable, avoiding excessive referencing. Where a standard or practice addresses more than one safety and control area, the results of such reviews should be cross-referenced.

It is preferred that the safety and control area reports are submitted concurrently or in a single package because some safety and control area reports may be needed as input for other reports. For example, the report for fitness for service may be used as input for the reports on physical design and safety analysis.

2.3.16 Integrated safety review final report

The licensee should prepare the ISR final report using the results of SCA reports and the global assessment. The ISR final report addresses the objectives of the ISR and the SCA review topics, and should include the following elements:

- summaries of the SCA reports

- global assessment that is based on the aggregate effect of the findings resulting from all safety and control areas, as well as the results each SCA review, taking the proposed corrective actions and safety improvements into account

- any findings related to the licensing and design bases, and disposition methods for these findings

- strengths, weaknesses, and interface issues from the SCA reports

-

strengths and weaknesses of the facility with respect to fulfilling the safety requirements of defence-in-depth,

particularly any elements relating to the basic safety functions of

- reactivity control

- fuel cooling

- confinement of radioactive materials

- safety significance and risk ranking of all the findings (any key safety issues identified should be addressed as soon as practicable, instead of waiting for the ISR process to be complete)

- mitigation methods, safety improvements, and corrective actions proposed for these findings

- statement of the licensee’s assessment of the overall acceptability of LTO of the NPP