Archived Web Page - Draft for Public Consultation RD-360 version 2: Life Management of Nuclear Power Plants

Archived information

Archived information is provided for reference, research or recordkeeping purposes. It is not subject to the Government of Canada Web Standards and has not been altered or updated since it was archived. Please contact us to request a format other than those available.

Preface

Nuclear power plants in Canada are subject to the ongoing regulatory oversight of the Canadian Nuclear Safety Commission to ensure their operation does not pose unreasonable risk to health, safety, security or the environment, and conforms to Canada’s international obligations regarding the peaceful use of nuclear energy.

Regulatory document RD-360 version 2, Life Management of Nuclear Power Plants describes the regulatory requirements for the long-term operation of a nuclear power plant (NPP) and for the end of its operation. The associated guidance document GD-360 Guidance for Life Management of Nuclear Power Plants (draft) [1] provides information as to how these requirements may be met.

Long-term operation of an NPP denotes operation beyond the assumed design life of the plant. The licensee may decide to maintain continued operation of the facility up to its refurbishment or permanent shutdown, or may initiate refurbishment activities to support the period of long-term operation. The licensee must provide assurances that the safety case is maintained for all activities authorized under the power reactor operating licence throughout the period of long-term operation. Specifically, the licensee must demonstrate that the NPP will continue to meet the licensing basis and seek opportunities to improve safety. This is accomplished through the completion of an Integrated Safety Review (ISR) which is a comprehensive evaluation of the design, condition, and operation of the NPP. The licensee addresses the results of the ISR through an integrated implementation plan (IIP).

The licensee may decide to end operation of the NPP. The end of operation is the final, permanent shutdown of an NPP’s reactor operation (or a unit of a multi-unit NPP facility); the NPP facility remains subject to its power reactor operating licence that authorizes activities during the transition period from reactor unit shutdown and safe state of storage until it enters the decommissioning phase. The licensee must then implement an end of operation plan, including a sustainable operations plan for the safe operation of the NPP until the final permanent shutdown of each reactor. Depending upon the strategy chosen, the end of operation plan must also include either a detailed decommissioning plan or a safe state of storage plan for the transition period until decommissioning the NPP.

Other health, safety and environmental considerations may dictate adherence to additional requirements. It is the responsibility of the licensee to identify any other applicable legislation or standards.

Table of Contents

3.2.2 Statement of the licensing basis at the time of initiating the ISR

3.2.3 Safety and control area reviews

3.2.4 Statement of modern codes, standards and practices

3.2.5 Identification and disposition of findings

3.2.6 Risk management decision-making process

3.2.7 Global assessment methodology

3.3 Safety and control area reports

3.4 Integrated safety review final report

1.0 Introduction

1.1 Purpose

This regulatory document explains the requirements of the Canadian Nuclear Safety Commission (CNSC) regarding activities a licensee must undertake in support of a project for long-term operation (LTO) or to prepare for the end of operation of a nuclear power plant (NPP) leading up to its decommissioning.

1.2 Scope

This regulatory document describes the steps and measures to be implemented by the licensee in support of a project for LTO, or for the end of operation of an NPP. LTO is the operation beyond the assumed design life of the NPP and may involve either continued operation of the NPP up to its refurbishment or permanent shutdown, or its refurbishment followed by the period of long-term operation. The end of operation is the final, permanent shutdown of reactor operation of an NPP (or unit of a multi-unit NPP facility); the NPP facility remains subject to a power reactor operating licence that authorizes activities during the transition period from reactor unit shutdown and safe state of storage until it enters the decommissioning phase.

This document covers activities to be completed during the operating phase of the NPP, under the authorization of a power reactor operating licence (PROL) issued by the Commission, and excludes activities that are to be undertaken under the decommissioning licence.

Requirements and activities pertaining to the conduct of an environmental assessment (EA) and/or application for a decommissioning licence are outside the scope of this regulatory document.

The associated guidance document GD-360 Guidance for Life Management of Nuclear Power Plants (draft) [1] provides information as to how these requirements may be met.

1.3 Relevant regulations

The provisions and regulations of the Nuclear Safety and Control Act (NSCA, the Act) that are relevant to this document are as follows:

- Subsection 24(4) of the NSCA states that “No licence may be issued, renewed, amended or replaced unless, in the opinion of the Commission, the applicant (a) is qualified to carry on the activity that the licence will authorize the licensee to carry on; and (b) will, in carrying on that activity, make adequate provision for the protection of the environment, the health and safety of persons and the maintenance of national security and measures required to implement international obligations to which Canada has agreed”.

- Subsection 24(5) of the NSCA states that “A licence may contain any term or condition that the Commission considers necessary for the purposes of this Act…”

- Section 3 of the General Nuclear Safety and Control Regulations states the general licence application requirements.

-

Paragraphs 12(1)(c), (f) and (i) of the

General Nuclear Safety and Control Regulations state that “Every licensee shall

(c) take all reasonable precautions to protect the environment and the health and safety of persons and to maintain security to maintain the security of nuclear facilities and of nuclear substances; …

(f) take all reasonable precautions to control the release of radioactive nuclear substances or hazardous substances within the site of the licensed activity and into the environment as a result of the licensed activity; …

(i) take all necessary measures to facilitate Canada’s compliance with any applicable safeguards agreement;”

1. Sections 3 and 6 of the Class I Nuclear Facilities Regulations state the general licence application requirements specific to nuclear facilities and the information required to apply for a nuclear facility operating licence.

Other acts, regulations, and codes are also applicable to projects to support LTO, including the Canadian Environmental Assessment Act (CEAA) [2] and associated regulations [3, 4, 5, 6, 7], and the Canada Labour Code, Part II, Occupational Health and Safety [7]. See also Additional Information.

1.4 National and international standards

Key principles and elements used in developing this regulatory document are consistent with national and international standards, guides and practices.

In addition, this regulatory document is consistent with:

- IAEA Safety Reports Series No. 57, Safe Long Term Operation of Nuclear Power Plants, 2008 [8]

- IAEA, Safety Standards Series No. NS-G-2.10, Periodic Safety Review of Nuclear Power Plants - Safety Guide, 2003 [9]

2.0 General Requirements

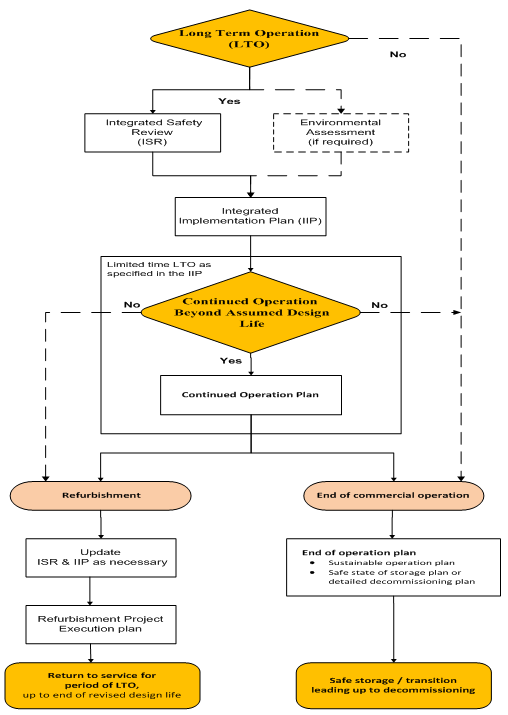

As the NPP approaches the end of its assumed design life, the licensee shall implement the steps and measures for either LTO or end of operation, as depicted in Appendix A. The licensee shall initiate this process at least five years before the NPP reaches the end of its assumed design life.

2.1 Long-term operation

The licensee shall notify the CNSC regarding its intent to continue operation beyond the end of assumed design life. The strategy for LTO involves two options:

- provide assurance that operational fitness is maintained up to facility refurbishment or permanent shutdown of its operation

- prepare for refurbishment

In support of LTO, the licensee shall:

- specify the proposed period of LTO

- describe the strategy to support the proposed period of LTO

- conduct an ISR, as described in section 3.1

- develop an integrated implementation plan (IIP), as described in section 3.5

- execute the IIP

Depending upon the option chosen, the licensee shall either submit a continued operation plan or a detailed refurbishment project execution plan, as described in sections 3.6 and 3.7 respectively.

Measures to implement LTO may constitute a project under the CEAA and may be subject to an EA. If this is the case, an EA will be conducted in accordance with the requirements established in the CEAA. The conduct of the EA is a separate process from the ISR and it is outside the scope of this regulatory document.

2.2 End of operation

The licensee shall notify the CNSC regarding its intent to cease operation. The licensee shall submit an end of operation plan including a sustainable operations plan and a safe state of storage plan, or a detailed decommissioning plan, as described in section 4.

3.0 Long-term Operation

If the decision is made to continue operation of the NPP beyond the assumed design life, the licensee shall complete the ISR and shall proceed in all cases with the execution of the IIP.

3.1 Integrated Safety Review

The ISR is a comprehensive evaluation of the design, condition and operation of the NPP. The objectives of the ISR are to determine:

- extent to which the NPP conforms to modern codes, standards and practices

- that the licensing basis will remain valid over the period of LTO

- adequacy of management arrangements to maintain safety of the NPP over the LTO operating period

- improvements that the licensee shall implement to resolve identified safety issues

The licensee shall conduct the ISR assuming a minimum operating period of 10 years. The licensee shall include the following:

- reviews that confirm the NPP meets and will continue to meet the current licensing and design basis

- reviews against modern codes, standards and practices to assess the level of safety compared to that of modern NPPs (any deviations from these modern codes, standards and practices are identified and their safety significance determined)

- identification of any modifications that are necessary to improve or maintain the level of safety over the proposed operating period of LTO

- an assessment of the actual physical condition of all safety related SSCs and demonstration that effects of aging will continue to be identified and managed for the proposed period of LTO

- the application of a global assessment methodology to evaluate the overall risk associated with safety for LTO, taking into account the aggregate effects of findings and proposed safety improvements

The licensee shall include the following documents in the ISR:

- ISR basis document

- safety and control area (SCA) reports

- ISR final report

The licensee shall conduct the safety reviews and prepare the SCA reports and ISR final report in accordance with the ISR basis document. Based on the current state of the NPP, the licensee shall identify and assess any non-conformance with the applicable requirements and expectations of modern codes, standards, and practices.

3.2 Integrated safety review basis document

The ISR basis document describes the scope and methodology of the ISR. The licensee shall establish a process to update the ISR basis document to include changes, for example, in project scope. The licensee shall submit updates or changes to the ISR basis document to the CNSC for review. The required elements of the ISR basis are described in sections 3.2.1 to 3.2.9.

3.2.1 Scope

In the ISR basis document the licensee shall describe the scope of the ISR. The licensee shall:

- indicate the proposed period of LTO

- describe the strategy for LTO (i.e., maintain continued operation of the facility up to its refurbishment or permanent shutdown, or initiate refurbishment activities to support the proposed period of LTO)

- address all aspects of the SCA as described in Appendix B

- identify the SSC and associated facilities covered by the ISR, addressing interdependencies on common services and site-wide issues

- consider relevant national and international operational experience pertaining to each SCA

- consider all expected modes of operation (e.g., normal operation, maintenance, refueling, shutdown, and start-up activities)

- address all generic safety issues and facility-specific safety issues

- take into consideration the operational state of each unit for a multi-unit facility, for example, safe storage, guaranteed shutdown state

- address management of the effects of plant aging and validity of safety analyses involving time-limited assumptions for the proposed period of LTO

3.2.2 Statement of the licensing basis at the time of initiating the ISR

The licensee shall document the licensing basis at the time of initiation of the ISR. The licensee shall use the licensing basis for conformity reviews and serve as a baseline in the review against modern codes, standards, and practices. Therefore, the licensee shall ensure that the current or modified licensing basis will remain valid over the proposed period of LTO.

3.2.3 Safety and control area reviews

The licensee shall identify the scope, review elements and methodologies applied to each SCA. The scope of the review of SCA may be adapted to ensure the focus of the review is appropriate to the period and the feasibility of LTO – see Appendix B for the SCA performance objectives.

3.2.4 Statement of modern codes, standards and practices

The licensee shall state all codes, standards and practices that will be used in the review of each SCA, including the criteria for their selection. The licensee shall state the “code effective date” for codes, standards and practices to be considered in the ISR. For each code, standard or practice listed, the licensee shall indicate the type of review to be performed.

3.2.5 Identification and disposition of findings

The licensee shall describe the processes for identifying, recording, categorizing, prioritizing and dispositioning findings. The licensee shall provide justifications for unresolved findings. The licensee shall confirm that any non-compliance with the current licensing basis or design basis will be immediately addressed. The licensee shall resolve non-conformance to modern codes, standards and practices to the extent practicable.

3.2.6 Risk management decision-making process

The licensee shall submit the proposed risk management decision-making process to evaluate and decide on the various alternatives to address findings identified in the ISR process.

3.2.7 Global assessment methodology

The licensee shall develop a methodology to carry out the global assessment that will be incorporated in the ISR final report. The licensee shall use this methodology to evaluate the safety case of the NPP. This includes:

- identifying strengths of NPP design and operation

- assigning safety significance and corresponding prioritization levels to the findings

- evaluating the interdependencies between the findings and also between their aggregate effects

- ensuring that the safety goals and limits, as well as principles of defence-in-depth, are satisfied

- formulating an overall risk judgment on the acceptability of continued operation of the NPP

The results from the global assessment are incorporated into the ISR final report.

3.2.8 Quality management program

The licensee shall establish, and describe in the ISR basis document, the quality management program for the conduct of the ISR.

3.2.9 Change control

The licensee shall establish a process to update the ISR basis document to include emerging issues and changes, for example, in project scope. The licensee shall submit updates or changes to the ISR basis document to the CNSC for review.

3.3 Safety and control area reports

The licensee shall conduct reviews for each SCA in accordance with the requirements of section 3.1. The licensee shall prepare ISR safety and control area reports for submission to CNSC. Based on the current state of the NPP, the licensee shall identify and assess any non-conformance with the applicable requirements and expectations of modern codes, standards and practices.

3.4 Integrated safety review final report

The licensee shall prepare an ISR final report that includes:

- significant ISR findings reported in the SCA reports

- results of applying the global assessment methodology

- an overall risk judgment on the acceptability of LTO of the NPP

- dispositioning of findings

- safety improvements and corrective actions for addressing findings

The licensee shall submit the ISR final report to the CNSC for review.

3.5 Integrated implementation plan

The licensee shall develop an integrated implementation plan (IIP) that addresses the results of the ISR to support the period of LTO. If an environmental assessment (EA) has been performed, the licensee shall ensure that the IIP integrates any action or follow-up program identified in the EA. In developing the IIP, the licensee shall confirm that assumptions for the project remain valid. This includes:

- the period of LTO

- the scope and stages of the project (i.e., continued operation or refurbishment)

- commitments or activities that were credited in the ISR or EA, for example, proposed modification, replacement or upgrade of components

The licensee shall assess the impact of any changes to the commitments or assumptions that were credited in the ISR documentation, including the impact of the changes on the IIP and provide justification.

In the IIP the licensee shall:

- state the period of LTO for the NPP

- state the date for when the NPP will transition to refurbishment or end of operation

- list the corrective actions and safety improvements to address all the ISR and EA findings

- specify the schedule for implementing the corrective actions and safety improvements

- specify the change control process for the IIP

- state the date for when the NPP will transition to end of operation

The licensee shall submit the IIP to the CNSC for review and acceptance and proceed with its implementation depending upon the strategy chosen for LTO.

3.6 Continued operation plan

If the decision is made to operate the NPP for a limited period beyond the assumed design life (less than 10 years) the licensee shall develop a continued operation plan to confirm that assumptions for the project remain valid, to specify the schedule for implementation of implement corrective actions and safety improvements identified in the IIP, and resolve ongoing action items that are necessary to support the LTO period up to the decision to either refurbish or end operation. The licensee shall ensure that the plan addresses all elements of SCAs authorized by the PROL.

3.7 Refurbishment and project execution plan

If the decision is made to refurbish, the licensee shall establish and implement a project execution plan. The implementation of the project execution plan may be preceded by a limited period of time of operation beyond the assumed design life. In such a case, before proceeding with the refurbishment project, the licensee shall update the ISR and IIP as necessary to account for any changes that have occurred between the completion of the IIP and the initiation of the refurbishment project (see Appendix A).

The licensee shall ensure that the refurbishment project execution plan includes the following:

- definition of the plant configuration during the refurbishment outage, including facilities, and in the case of multi-unit stations, common services affected by the outage

- modifications to any programs, processes or procedures taking into account changes to the nature of the work performed, number of workers, and worker qualification

- refurbishment construction program, including activities related to design, procurement, and construction of new, modified and refurbished SSCs

- commissioning program describing the systematic approach to SSC testing and facility integrated testing

- management system in place governing refurbishment activities

4.0 End of Operation Plan

If a decision is made to cease operation of the NPP, the licensee shall establish and implement an end of operation plan at least five years prior to its final, permanent shutdown. The licensee shall describe the strategy, arrangements and activities the licensee will take to provide assurance of the safe of operation of the NPP until the final shutdown of each reactor unit(s) and for the transition period until the NPP begins decommissioning.

The licensee shall specify the following:

- the estimated date for final permanent shutdown of each reactor unit

- the date by which the licensee is planning to apply for a decommissioning licence

- a sustainable operations plan addressing the period of operation up to permanent shutdown of each reactor unit

The licensee shall also include either:

- a safe state of storage plan if the licensee’s strategy involves a period of deferment prior to NPP decommissioning, or

- a detailed decommissioning plan if the licensee’s strategy involves proceeding immediately with the decommissioning of the NPP after the permanent shutdown of the reactor unit(s).

4.1 Sustainable operations plan

The licensee shall ensure that the sustainable operations plan describes the arrangements and activities required to demonstrate that safe and reliable operation of the NPP will be maintained and sustained, for each SCA covered under the PROL, for the period of operation up until each reactor unit is permanently shut down.

The licensee shall ensure that the plan addresses all elements of SCAs authorized by the PROL, and provide information on the duration, schedule and milestones for the execution of activities, if applicable.

4.2 Safe state of storage plan

If the licensee intends to defer decommissioning the NPP, the licensee shall establish and implement a safe state of storage plan.

The licensee shall describe the arrangements and activities required to put the reactor unit(s) in a safe state of storage and ensure their monitoring until its decommissioning. The licensee shall include a stabilization activity plan and a storage and surveillance plan.

4.2.1 Stabilization activity plan

The licensee shall describe the arrangements and activities that will be conducted to ensure the safe transition of the NPP reactor unit(s) from a final shutdown state to the safe storage state. The licensee shall include information on the NPP configuration during safe storage phase and the tasks and processes to implement this configuration.

4.2.2 Storage and surveillance plan

The licensee shall describe the arrangements and activities required to ensure maintenance of the safe storage state and its surveillance during the period of deferment prior to final dismantlement and decommissioning of the NPP.

As these activities will be conducted under the PROL, the licensee shall address, as appropriate, all elements of SCAs authorized by the licence, and provide information on the duration, schedule and milestones for their execution.

4.3 Decommissioning plan

If the licensee intends to proceed immediately with decommissioning after the end of operation, the licensee shall prepare a detailed decommissioning plan in support of an application for a decommissioning licence. The licensee shall prepare the application for a licence to decommission in accordance with the NSCA and its regulations, specifically with section 7 of the Class I Nuclear Facilities Regulations, and other applicable requirements. The licence to decommission is required prior to commencing the execution of decommissioning activities.

Glossary

- assumed design life

- The period of operation that was originally anticipated at the design phase for the NPP. It is used as a reference or target for planning activities including the design of SSCs that can affect the safe operation of the NPP. (For the purposes of this regulatory document and for the current operating CANDU power reactors, unless otherwise stated, the “assumed design life” of an NPP is 30 years, based on 0.8 capacity factor of nominal full power, i.e. 210,000 EFPH from the date of its first criticality. For multi-unit NPP facilities, the assumed design life for the facility is based on the date at which the first unit reached first criticality.)

- codes, standards, and practices

- The information contained in guidance documents and in modern industrial codes, guides, and standards. Practices need to take into account known related design improvements for structures, systems and components as well as operating experience and findings from technical developments (e.g., new knowledge on the cumulative effects of aging, results of reactor physics research and development, human factors engineering, human reliability and software engineering). See also “modern codes, standards, and practices”.

- design basis

- The range of conditions and events taken explicitly into account in the design of structures, systems, and components of a nuclear facility, according to established criteria, such that the facility can withstand them without exceeding authorized limits by the planned operation of safety systems. The design basis includes the design description, design manuals, design drawings and the safety analysis report.

- EFPH

- effective full power hour; the period over which a component sees service that equals the amount of full service the component would have experienced if it was operated continuously over a full hour.

- end of operation

- Final, permanent shutdown of reactor operation of an NPP (or unit of a multi-unit NPP facility). The NPP facility remains subject to a power reactor operating licence that authorizes activities during the transition period from reactor unit shutdown and safe state of storage until it enters the decommissioning phase.

- finding

- A piece of information obtained or a conclusion reached when specific statements or actual conditions are compared with what is required, expected, accepted or practiced.

- generic safety issues

- Unresolved safety-related issues, common to all NPP designs, requiring corrective actions be taken by the licensees within a reasonable time frame.

- global assessment methodology

- A methodology or means of formulating an overall risk judgment on the acceptability of continued safe operation of the nuclear facility for the proposed period of life extension.

- integrated implementation plan (IIP)

- A plan that considers the technical scope and schedule of the project to support operation beyond assumed design life by taking into account the results of an environmental assessment (EA), where required, and an Integrated Safety Review (ISR).

- integrated safety review (ISR)

- A comprehensive assessment of nuclear facility design and operation that deals with the cumulative effects of aging, modifications, operating experience, technical developments and siting aspects, and aims at ensuring a high level of safety throughout the operating life of the facility (or activity).

- integrated safety review (ISR) basis document

- The information that sets out the scope and methodology for the conduct of the ISR.

- long-term operation (LTO)

- The operation beyond the assumed design life of the NPP, which has been justified by the results of an integrated safety review taking into consideration the conditions of structures, systems, and components (SSC), life limiting processes, and a review of the plant design and operational measures in place against modern codes and practices.

- licensing basis

- For a regulated facility or activity, a set of requirements and documents comprising:

- regulatory requirements set out in the applicable laws and regulations

- conditions and safety and control measures described in the facility’s or activity’s licence and the documents directly referenced in that licence

- safety and control measures described in the licence application and the documents needed to support that licence application

- modern codes, standards, and practices

- The set of objectives, requirements, and experience for the siting, design, construction, commissioning, operation, and decommissioning of a nuclear facility if it were to be built at the time of the initiation of the project to support long-term operation.

- nuclear facility

- For the purposes of this document, a nuclear power plant; it includes, where applicable, the land on which the reactor is located, a building that forms part of or equipment used in conjunction with the reactor, and any system for the management, storage, or disposal of a nuclear substance.

- refurbishment

- An activity or a set of activities aimed at restoring the condition of one or several structures, systems, or components to a state that is comparable to the condition of a new structure, system, or component.

- safety case

- An integrated collection of arguments and evidence to demonstrate the safety of the facility and that all applicable regulatory requirements are met. This will normally include a safety assessment, but could also typically include information (including supporting evidence and reasoning) on the robustness and reliability of the safety assessment and the assumptions made therein.

- safety goal

- Objective to protect reactor facility staff, the public and the environment from harm by establishing and maintaining effective defences against the release of the radiological hazards.

- safety significance

- The significance of a discovery or issue with respect to the impact on meeting the fundamental nuclear safety objectives as defined by the IAEA 1 . In general, a discovery or event has safety significance if it denotes a deviation away from the safety case accepted in the licence, in a direction detrimental to safety, such as:

- reducing margins to, or exceeding the accepted limits

- increasing risk

- impairments (various degrees) of the special safety systems or of the safety functions for accident mitigation

- human factor issues

- events causing radioactive releases and spills of hazardous substances, injuries to workers, public, etc.

- structures, systems and components (SSC)

- A general term encompassing all of the elements (items) of a facility or activity that contribute to protection and safety, except human factors. Structures are the passive elements: buildings, vessels, shielding, etc. A system comprises several components, assembled in such a way as to perform a specific (active) function. A component is a discrete element of a system. Examples are wires, transistors, integrated circuits, motors, relays, solenoids, pipes, fittings, pumps, tanks, and valves.

- storage with surveillance

- A planned stage during a decommissioning program during which the remaining nuclear substances, equipment, and site(s) are placed under controlled surveillance for a specified period of time. Note: Licensing control by the regulatory authority remains in effect during such periods.

- time-limited assumptions (TLA)

- Assumptions used in certain plant- or SSC-specific safety or design analyses that are based on an explicitly specified length of plant or SSC life; for example, metal fatigue calculation, pressurized thermal shock (PTS) analysis, radiation-induced deformation and embrittlement, thermal aging, loss of material and equipment qualification of electrical and I&C cables are included in the analyses.

Appendix A: Life Management of Nuclear Power Plants

Appendix B: CNSC Safety and Control Areas

Functional Area |

Safety and Control Areas |

Performance Objectives |

|

Management |

Management System |

Adequate management oversight of the control and implementation of activities defined by the documented series of processes. |

Human Performance Management |

Continued and consistent safe performance of a nuclear facility through a system of programs, policies, standards and procedures. |

|

Operating Performance |

Safe and secure plant operation with adequate regard for health, safety, security, environmental protection and international obligations. |

|

|

Facility and Equipment |

Safety Analysis |

Demonstrated acceptability of the consequences of design basis events, the capability of protective systems to adequately control power, cool the fuel and contain any radioactivity that could be released from the plant. |

Physical Design |

A design basis that remains valid for all systems, structures and components. |

|

Fitness for Service |

Structures, systems, and components whose performance may affect safe operations or security remain available, reliable and effective, consistent with the design, quality control measures and analysis documents. |

|

|

Core Control Processes |

Radiation Protection |

Adequate protection of the health and safety of persons inside the facility with respect to ionizing radiation. |

Conventional Health and Safety |

Conventional health and safety work practices and conditions achieve a high degree of personnel safety. |

|

Environmental Protection |

Protection of the environment and the health and safety of persons by taking all reasonable precautions, including identifying, controlling, and monitoring the release of radioactive substances and hazardous substances to the environment. |

|

Emergency Management and Fire Protection |

Adequate provisions for preparedness and response capability that would mitigate the effects of accidental releases of nuclear substances and hazardous substances on the environment, the health and safety of persons and the maintenance of national security. |

|

Waste Management |

An acceptable waste management program would be facility and waste stream specific. However, it would be CNSC staff’s expectation that licensees develop, implement and audit their internal waste management programs and include waste management as a key component of their corporate and safety culture. |

|

Security |

Provisions for a physical protection program to provide the required security for the facility and its operations. |

|

Safeguards |

Conformity with measures required by the facility to meet Canada’s international safeguards obligations through: timely and accurate provision of reports on nuclear materials provision of access and assistance to IAEA inspectors for verification activities submission of annual operational information and accurate design information of plant structures, processes and procedures development and satisfactory implementation of appropriate facility safeguards procedures |

|

Packaging and Transport |

Adherence to the CNSC Packaging and Transport of Nuclear Substances Regulations and Transport Canada Transportation of Dangerous Goods Regulations for all shipments leaving the site. Shipments of nuclear substances within the nuclear facility where access to the property is controlled are exempted from the application of the Packaging and Transport of Nuclear Substances Regulations. |

1 IAEA, INSAG 12, Basic Safety Principles for Nuclear Power Plants 75-INSAG-3 Rev. 1, Vienna, 1999.

References

- CNSC, GD-360 Guidance for Life Management of Nuclear Power Plants (draft).

- Canadian Environmental Assessment Act, S.C. 1992, c. 37.

- Canadian Environmental Assessment Act, Comprehensive Study List Regulations, SOR/94-638.

- Canadian Environmental Assessment Act, Exclusion List Regulations, SOR/2007-108.

- Canadian Environmental Assessment Act, Inclusion List Regulations, SOR/94-637.

- Canadian Environmental Assessment Act, Law List Regulations, SOR/94-636.

- Canadian Environmental Assessment Act, Procedures for an Assessment by a Review Panel, guidelines issues pursuant to the Act, November 1997.

- IAEA Safety Reports Series No. 57, Safe Long Term Operation of Nuclear Power Plants, Vienna, 2008.

- IAEA, Safety Standards Series No. NS-G-2.10, Periodic Safety Review of Nuclear Power Plants—Safety Guide, Vienna, 2003

- Government of Canada, Canada Labour Code, Part II, Occupational Health and Safety, R.S., 1985, c. L-2, 2009.

Additional Information

The following documents contain additional information that may be of interest to persons involved in long-term or end of operation activities of a nuclear power plant:

- Canadian Environmental Assessment Agency, Operational Policy Statement, Preparing Project Descriptions under the Canadian Environmental Assessment Act, Ottawa, 2000.

- Canadian Nuclear Safety Commission (CNSC), INFO-0774 Environmental Assessment Screening Process at CNSC, Ottawa, Canada 2009.

- CNSC, RD-334 Aging Management for Nuclear Power Plants, Ottawa, 2011.

- CNSC, P-242, Considering Cost-benefit Information, Ottawa, 2000.

- CNSC, S-99, Reporting Requirements for Operating Nuclear Power Plants, Ottawa, 2003.

- CNSC, G-219, Decommissioning Planning for Licensed Activities, Ottawa, 2000.

- CNSC, G-206, Financial Guarantees for the Decommissioning of Licensed Activities, Ottawa, 2000.

- CNSC, G-320, Accessing the Long Term Safety of Radioactive Waste Management, Ottawa, 2006.

- IAEA, Ageing Management for Nuclear Power Plants, Safety Standards Series, Safety Guide NS-G-2.12, Vienna, 2009.

- IAEA, Maintenance, Surveillance and In-service Inspection in Nuclear Power Plants, Safety Standards Series, Safety Guide NS-G-2.6, Vienna, 2002.

- IAEA, Safety Report Series No.26, Safe Enclosure of Nuclear Facilities During Deferred Dismantling, Vienna, 2002.

- Nuclear Fuel Waste Act, S.C. 2002, c. 23.

Page details

- Date modified: