REGDOC-2.13.2, Import and Export, version 2

Preface

This regulatory document is part of the CNSC's safeguards and non-proliferation series of regulatory documents, which also covers regulatory controls on import and export of prescribed items. The full list of the CNSC’s series of regulatory document series is included at the end of this document and can also be found on the CNSC’s Regulatory Documents Web page.

Part I of regulatory document REGDOC-2.13.2, Import and Export, sets out the CNSC’s guidance for current and prospective licensees who intend to import or export nuclear and nuclear-related dual-use items, also known as controlled nuclear substances, equipment and information. The latter are identified in Appendix E, which is a copy of the existing schedule of the Nuclear Non-proliferation Import and Export Control Regulations (NNIECR). The legislation relevant to the import and export of these items is provided, along with an overview of the domestic and international contexts that form the basis of import and export controls for these items. The licensing program is outlined and information is provided on how to apply for a licence and amend an existing licence, and on application processing times.

Part II of regulatory document REGDOC-2.13.2, Import and Export, sets out the CNSC’s guidance for current and prospective licensees who intend to import or export risk-significant radioactive sources (Category 1 and 2 radioactive sources). This guidance supersedes INFO-0791 – Control of the Export and Import of Risk-Significant Radioactive Sources.

This document examines the type of information the CNSC considers when assessing applications for the import or export of controlled nuclear substances, equipment and information. Further information is also provided for exporters on the end-use control, which allows the CNSC to require exporters to apply for a licence for items that are not otherwise listed in the Appendix E when they may be intended for use in connection with a nuclear weapons program. Finally, the CNSC’s activities to verify and enforce regulatory compliance are considered.

Requirements associated with this document are found in the Nuclear Safety and Control Act (NSCA), the General Nuclear Safety and Control Regulations (GNSCR) and the Appendix E.

Important note: Where referenced in a licence either directly or indirectly (such as through licensee-referenced documents), this document is part of the licensing basis for a regulated facility or activity.

The licensing basis sets the boundary conditions for acceptable performance at a regulated facility or activity, and establishes the basis for the CNSC’s compliance program for that regulated facility or activity.

Where this document is part of the licensing basis, the word "shall" is used to express a requirement to be satisfied by the licensee or licence applicant. "Should" is used to express guidance or that which is advised. "May" is used to express an option or that which is advised or permissible within the limits of this regulatory document. "Can" is used to express possibility or capability.

Nothing contained in this document is to be construed as relieving any licensee from any other pertinent requirements. It is the licensee’s responsibility to identify and comply with all applicable regulations and licence conditions.

Table of Contents

- 1. Purpose

- 2. Scope

- 3. Relevant Legislation

- Part I: Nuclear and Nuclear-Related Dual-Use Items

- 4. Program Framework

- 5. Licensing Process

- 6. Evaluation of Licence Applications

- 7. End-Use Controls for Nuclear-Related Dual-Use Items

- 8. Compliance with CNSC requirements

- Part II: Risk-Significant Radioactive Sources

- 9. Program Framework

- 10. Risk-Significant Radioactive Sources

- 11. Licensing and Control Process

- 12. Evaluation and Licence Applications

- 13. Program Framework

- Appendix A: Examples of Possible Suspicious Inquiries or Orders

- Appendix B: Disclosure of Non-Compliance

- Appendix C: How to Complete Import and Export Applications for Nuclear and Nuclear-Related Dual-Use Items

- Appendix D: How to Complete an Export Application for Risk-Significant Radioactive Sources

- Appendix E: Controlled Nuclear Substances, Equipment and Information

- Glossary

- References

1. Purpose

Part I of REGDOC-2.13.2, Import and Export, sets out the guidance of the Canadian Nuclear Safety Commission (CNSC) for current and prospective licensees who intend to import or export nuclear and nuclear-related dual-use items, also known as controlled nuclear substances, equipment and information.

Part II of REGDOC-2.13.2, Import and Export sets out the guidance of the CNSC for current and prospective licensees who intend to import or export risk-significant radioactive sources (Category 1 and 2 radioactive sources), as set out in International Atomic Energy Agency (IAEA) RS-G-1.9, Categorization of Radioactive Sources.

2. Scope

This document describes the regulatory and policy basis for the CNSC’s import and export control program with respect to nuclear and nuclear-related dual-use items, and to risk-significant radioactive sources (Category 1 and 2 radioactive sources). Information is also provided with respect to:

- when potential applicants should contact the CNSC

- applying for an import or export licence or amending or transferring existing licences

- CNSC criteria when evaluating licence applications

- the end-use control for nuclear-related dual-use items

- how the CNSC verifies compliance with regulatory requirements

- controlled nuclear substances, equipment and information

3. Relevant Legislation

The provisions of the Nuclear Safety and Control Act (NSCA), the General Nuclear Safety and Control Regulations (GNSCR) and the Nuclear Non-proliferation Import and Export Control Regulations (NNIECR) relevant to this document include:

- paragraph 3(b) of the NSCA, which provides that "The purpose of this Act is to provide for the implementation in Canada of measures to which Canada has agreed respecting international control of the development, production and use of nuclear energy, including the non-proliferation of nuclear weapons and nuclear explosive devices."

- subsection 24(5) of the NSCA, which provides that "A licence may contain any term or condition that the Commission considers necessary for the purposes of this Act..."

- paragraph 26(a) of the NSCA, which provides that "Subject to the regulations, no person shall, except in accordance with a licence: (a) possess, transfer, import, export, use or abandon a nuclear substance, prescribed equipment or prescribed information."

- paragraph 48(c) of the NSCA, which provides that "Every person commits an offence who fails to comply with any condition of a licence."

- paragraph 48(d) of the NSCA, which provides that "Every person commits an offence who knowingly makes a false or misleading written or oral statement to the Commission, a designated officer or an inspector."

- paragraph 48(k) of the NSCA, which provides that "Every person commits an offence who fails to comply with this Act or any regulation made pursuant to this Act."

- section 50 of the NSCA, which provides that "Every person commits an offence who, except as authorized by this Act, possesses a nuclear substance, prescribed equipment or prescribed information that is capable of being used to produce a nuclear weapon or a nuclear explosive device."

- subsection 3(2) of the GNSCR, which provides that "Subsection (1) does not apply in respect of an application for a licence to import or export for which the information requirements are prescribed by the Nuclear Non-proliferation Import and Export Control Regulations..."

- paragraph 10(b) of the GNSCR, which provides that "Naturally occurring nuclear substances, other than those that have been associated with the development, production or use of nuclear energy, are exempt from the application of all provisions of the Act and the regulations made under the Act except the following... (b) in the case of a nuclear substance listed in the schedule to the Nuclear Non-proliferation Import and Export Control Regulations, the provisions that govern the import and export of nuclear substances."

- section 18 of the GNSCR, which provides that "On importing or exporting a nuclear substance, prescribed equipment or prescribed information, the licensee shall present the required import or export licence to a customs officer."

- paragraph 20(d) of the GNSCR, which provides that "Each of the following items is prescribed equipment for the purposes of the Act... (d) equipment that is capable of being used in the design, production, operation or maintenance of a nuclear weapon or nuclear explosive device."

- paragraph 21(1)(a) of the GNSCR, which provides that "Information that concerns any of the following, including a record of that information, is prescribed information for the purposes of the Act: (a) a nuclear substance that is required for the design, production, use, operation or maintenance of a nuclear explosive device, including the properties of the nuclear substance."

- paragraph 21(1)(b) of the GNSCR, which provides that "Information that concerns any of the following, including a record of that information, is prescribed information for the purposes of the Act... (b) the design, production, use, operation or maintenance of a nuclear weapon or nuclear explosive device."

- subsection 23(2) of the GNSCR, which provides that "A person who possesses or has knowledge of prescribed information shall take all necessary precautions to prevent any transfer or disclosure of the prescribed information that is not authorized by the Act and the regulations made under the Act."

- subsection 1(2) of the NNIECR, which provides that "All controlled nuclear substances are prescribed as nuclear substances for the purpose of paragraph (d) of the definition "nuclear substance" in Section 2 of the Act, with respect to the import and export of those substances."

- subsection 1(3) of the NNIECR, which provides that "All controlled nuclear equipment is prescribed equipment for the purposes of the Act, with respect to the import and export of equipment."

- subsection 1(4) of the NNIECR, which provides that "All controlled nuclear information is prescribed information for the purposes of the Act, with respect to the import and export of that information, unless it is made public in accordance with the Act, the regulations made under the Act or a licence."

-

subsection 3(1) of the NNIECR, which provides that "An application for a licence to import or export a controlled nuclear substance, controlled nuclear equipment or controlled nuclear information shall contain the following information:

- (a) the applicant’s name, address and telephone number;

- (b) a description of the substance, equipment or information, including its quantity and the number of the paragraph of the schedule in which it is referred to;

- (c) the name and address of the supplier;

- (d) the country of origin of the substance, equipment or information;

- (e) the name, address and, where the application is for a licence to import, telephone number of each consignee;

- (f) the intended end-use of the substance, equipment or information by the final consignee and the intended end-use location;

- (g) the number of any licence to possess the substance, equipment or information; and

- (h) where the application is in respect of a controlled substance that is Category I, II or III nuclear material, as defined in section 1 of the Nuclear Security Regulations, the measures that will be taken to facilitate Canada’s compliance with the Convention on the Physical Protection of Nuclear Material, INFCIRC/274/Rev.1."

-

subsection 4(1) of the NNIECR, which provides that "A person may carry on any of the following activities without a licence to carry on that activity:

- (a) import a controlled nuclear substance referred to in Part B of the schedule that is not a radioactive nuclide;

- (b) import controlled nuclear equipment referred to in paragraph A.3 or Part B of the schedule;

- (c) import controlled nuclear information that relates to a controlled nuclear substance or controlled nuclear equipment referred to in paragraph A.3 or Part B of the schedule;

- (d) import a controlled nuclear substance, controlled nuclear equipment or controlled nuclear information for the purpose of placing it in transit;

- (e) export a controlled nuclear substance, controlled nuclear equipment or controlled nuclear information after it has been in transit; or

- (f) export the controlled nuclear substance referred to in paragraph A.1.4. of the schedule that is not for use in a nuclear reactor to any Participating Government of the Nuclear Suppliers Group."

Part I: Nuclear and Nuclear-Related Dual-Use Items

4. Program Framework

4.1 Overview

This section outlines the basis for import and export controls implemented by the CNSC for controlled nuclear substances, equipment and information.

Canada controls the import and export of a number of goods for various reasons, including regulation of trade in strategic and military goods, prevention of proliferation of weapons of mass destruction, and fulfillment of international obligations. One of the main objectives of controlling the transfer of sensitive nuclear-related items is to prevent illicit transfers to a nuclear weapons program while facilitating legitimate commerce.

Effective import and export controls are based on an interrelated set of domestic and international laws, regulations, agreements and best practices. The domestic context is comprised of national legislation and Canadian nuclear non-proliferation policy, while the international context is influenced by the Treaty on the Non-Proliferation of Nuclear Weapons and multilateral export control regimes.

Sections 4.2 and 4.3 of this document provide further information on the domestic and international aspects of the CNSC’s import and export controls.

4.2 The domestic context

Legislation: the Nuclear Safety and Control Act and the Nuclear Non-proliferation Import and Export Control Regulations.

The CNSC regulates the use of nuclear energy and materials to protect the health, safety and security of Canadians as well as the environment, and to implement measures to which Canada has agreed respecting international control of the development, production and use of nuclear energy, including the non-proliferation of nuclear weapons and nuclear explosive devices. Pursuant to the NSCA, the CNSC licenses, regulates and establishes technical requirements for all nuclear-related activities in Canada.

Appendix E lists controlled nuclear substances, equipment and information. Appendix E is comprised of two parts: Part A lists nuclear items and Part B lists nuclear-related dual-use items. For this reason, controlled nuclear substances, equipment and information are also referred to as nuclear and nuclear-related dual-use items.

The items listed in Part A are those especially designed or prepared for nuclear use. Examples include:

- nuclear material (uranium, plutonium, thorium)

- nuclear reactors and equipment

- non-nuclear material used in reactors (heavy water, deuterium, graphite)

- plants and equipment for conversion, enrichment and reprocessing of nuclear material and for fuel fabrication and heavy water production

- technology associated with any of the foregoing items

The items listed in Part B are those that have legitimate non-nuclear applications, but that could also make a significant contribution to an unsafeguarded nuclear fuel cycle or nuclear explosive activity. Examples include:

- nickel powder and lithium

- machine tools

- implosion systems development equipment

- high explosives and related equipment

- technology associated with any of the aforementioned items

Canada’s nuclear non-proliferation policy

Canada was the first country with substantial nuclear capability to reject the development and acquisition of nuclear weapons, and has been actively involved in the international promotion of the peaceful uses of nuclear energy. The two objectives of Canada’s nuclear non-proliferation policy are to:

- assure Canadians and the international community that Canada’s nuclear exports do not contribute to the development of nuclear weapons or other nuclear explosive devices

- promote a more effective and comprehensive international nuclear non-proliferation regime

The policy provides that Canadian-supplied nuclear material, equipment, non-nuclear material and technology may only be transferred to countries with which Canada has concluded a bilateral nuclear cooperation agreement (NCA).

The CNSC – along with its predecessor, the Atomic Energy Control Board – has contributed to fulfilling Canada’s international obligations and commitments on the peaceful uses of nuclear energy since 1946. Accordingly, the CNSC has substantive involvement in implementing key aspects of Canada’s nuclear non-proliferation policy. This includes making sure that major nuclear exports are made subject to a NCA. NCAs, which are treaty-level documents negotiated by Global Affairs Canada, establish reciprocal obligations (between Canada and the partner country) that are designed to minimize the risk of proliferation associated with the international transfer of major nuclear items. The CNSC implements the terms and conditions of these agreements through the administrative arrangements (AAs) that it concludes with its counterpart in the partner country.

Key provisions contained in Canada’s NCAs include: peaceful, non-explosive end-use assurances; control over retransfer to third parties of Canadian-obligated items; control over reprocessing of Canadian-obligated uranium; control over the high enrichment of Canadian-obligated uranium; provisions for fall-back safeguards; and adequate physical protection of Canadian-obligated items.

Some licensing applications for the import and export of controlled nuclear substances, equipment and information may invoke the implementation of provisions of bilateral NCAs and AAs by the CNSC as part of the licensing assessment and decision process. Section 6.2 of this document provides information on this process.

Foreign-origin uranium

Canadian exports of uranium for nuclear use include not only Canadian-origin uranium, but also foreign-origin uranium imported into Canada for commercial processing before delivery to another country. In those instances where foreign-origin uranium imported to Canada for commercial processing does not carry a foreign obligation, this uranium will be made subject to the terms and conditions of an NCA between Canada and the recipient country at the time of export.

4.3 The international context

Treaty on the Non-Proliferation of Nuclear Weapons

The Treaty on the Non-Proliferation of Nuclear Weapons (NPT) is the cornerstone of the international nuclear non-proliferation regime. Signatories to the NPT commit to prevent the spread of nuclear weapons, promote cooperation in the peaceful uses of nuclear energy, and achieve nuclear disarmament.

Through the NSCA and corresponding regulations, the CNSC implements the following commitments that Canada, as a signatory to the NPT, has agreed to:

- not to receive, manufacture or acquire nuclear weapons or other nuclear explosive devices

- to accept IAEA safeguards on all nuclear material in Canada

- to ensure that Canada’s nuclear exports to non-nuclear-weapons states are subject to IAEA safeguards

Multilateral export control groups

Multilateral export control groups are another important element of the international nuclear non-proliferation regime. Canada is a member of the Zangger Committee and the Nuclear Suppliers Group (NSG), which are export control regimes that help ensure that nuclear and nuclear-related dual-use items are only used for peaceful purposes. States that are members of these regimes agree by consensus on lists of items whose transfer must be controlled. Implementation of these controls is done in accordance with domestic export control laws and practices, including national export licensing requirements. Appendix E is based on the lists of items agreed by the Zangger Committee and NSG.

5. Licensing Process

5.1 Overview

The import and export of the controlled items in the NNIECR require a licence from the CNSC, except for activities exempted under subsection 4(1) of the NNIECR.

The CNSC has established a risk-based licensing program for these imports and exports. This program ensures that imports and exports of nuclear and nuclear-related dual-use items conform to domestic regulatory requirements, Canadian nuclear non-proliferation policy and Canada’s international obligations.

For Canadian nuclear facilities, the Commission makes most licensing decisions on the basis of the technical support and recommendations of CNSC staff. For import and export licensing, however, the Commission has delegated this authority pursuant to subsection 37(1) of the NSCA to a designated officer. It is the designated officer who makes decisions to issue, amend, replace, renew, authorize the transfer of, suspend or revoke import and export licences.

Revocation, amendment and replacement of an export licence or an import licence by a designated officer will be considered on the basis of an application submitted pursuant to requirements and information specified in section 6 of the GNSCR.

5.2 How to apply for a CNSC import or export licence

The CNSC has developed application forms for import licences (Application for a Licence to Import Nuclear Items) and export licences (Application for a Licence to Export Nuclear and Nuclear-Related Dual-Use Items). Appendix C of this document provides detailed information on completing these forms, and also includes copies of them for reference.

The information required in support of a CNSC import or export application can be found in subsection 3(1) of the NNIECR. Completed import and export licence applications should be submitted to the CNSC’s Licensing Administrator (Nuclear), via mail, fax or email:

Licensing Administrator (Nuclear)

Non-Proliferation and Export Controls Division

Directorate of Security and Safeguards

Canadian Nuclear Safety Commission, P.O. Box 1046, Station B

280 Slater Street, Ottawa, ON K1P 5S9

Fax: 613-995-5086

Email: export-import@cnsc-ccsn.gc.ca

5.3 What import and export licences authorize

A CNSC import or export licence authorizes a licensee (the person or organization to whom the licence has been issued) to carry out the import or export activity defined in the licence. A licence is transaction-specific and identifies the item, quantity, end-use, end-user and consignee. It may authorize the transfer of a defined quantity of items in single or multiple shipments, depending upon the commercial arrangement; however, the quantity authorized cannot be exceeded and all shipments must take place within the defined duration of the licence.

A licence may also authorize shipments to single or multiple consignees in a given country. The licence is generally valid for one year, but an applicant may request a longer licence period to accommodate a commercial contract.

Some licences contain compliance conditions that are related to reporting requirements, such as shipment notifications or annual summaries of shipments. Section 8 of this document provides information on compliance with licence conditions that may be included in CNSC import and export licences.

5.4 Licence amendments and transfers

A CNSC import or export licence may be amended to:

- change the expiry date

- add or remove consignees

- add or remove items authorized for import or export

- change the sender or recipient address

- change the quantity of items on the existing licence

- modify the end-use

To request a licence amendment, use the application forms referenced in section 5.2 of this document. Select the "Amendment – Licence number" box and identify the number of the existing licence in question. When applying for amendment(s), only complete the relevant section(s) of the application form.

Please note: A licence cannot be amended once the authorized quantity has been imported or exported. Similarly, an amendment cannot be made after a licence has expired. Therefore, applications to amend licences should be received by the CNSC at least 15 business days before the amended licence is required.

The transfer of a CNSC import or export licence from an existing licensee (the transferor) to another entity (the transferee) may be authorized by the CNSC upon consideration of an application submitted by both entities. Licence transfers may be authorized where a change of legal status has occurred and it can be verified that the new licensee (the transferee) is capable of ensuring compliance with the NSCA, relevant regulations and all licence conditions. If significant changes to the terms and conditions are also proposed, a transfer will not be authorized and the applicant for the licence will need to apply for issuance of a new licence. Further information can be obtained by contacting the CNSC’s Licensing Administrator (Nuclear).

5.5 Processing time and service standards

Applicants can generally expect the CNSC to decide upon the issuance of an import or export licence within 15 business days of receiving a complete application. Incomplete applications cannot be processed, and additional information will be required before the assessment can proceed.

While the CNSC strives to process all applications within 15 business days, delays may be incurred for export licence applications that require international communications and/or consultations. For example, exports of items in Part A of Appendix E of this document may be subject to bilateral NCAs. In such cases, the CNSC must first ensure that appropriate notifications are exchanged with a partner country before an export can be authorized. Depending upon the country, it may take up to 30 business days to ensure the appropriate conditions are in place for the transfer. In such cases, the CNSC will keep the applicant apprised of the expected timeline to complete the assessment. Applicants are always encouraged to apply for an export licence at the earliest opportunity.

The CNSC website provides more information on service standards for import and export licences.

5.6 Non-CNSC export requirements

Along with the export authorization required from the CNSC for nuclear and nuclear-related dual-use items, the export of these items may also be controlled by Global Affairs Canada pursuant to the Export and Import Permits Act and its corresponding Export Control List. Exporters can obtain further information on these licensing requirements by contacting:

Trade Controls Bureau (TIE)

Global Affairs Canada

125 Sussex Drive

Ottawa, ON K1A 0G2

Telephone: 613-996-2387

Fax: 613-996-9933

Email: tie.reception@international.gc.ca

Internet: exportcontrols.gc.ca

6. Evaluation of Licence Applications

6.1 Receipt of application

Upon receipt of an import and export licence application, the CNSC sends an email of acknowledgement to the applicant. This acknowledgement message assigns a reference number to the application, which both the applicant and the CNSC should use in any future correspondence.

The CNSC screens the application to ensure that all information described in section 3 of the NNIECR has been submitted by the applicant. If any information is missing, the CNSC will ask the applicant to submit it. For applications concerning a controlled nuclear substance, the CNSC will also consider if the applicant requires a licence to possess or use the substance.

Note: This initial screening does not consider the quality of an application or its technical aspects.

6.2 Assessment of application

The CNSC assesses the licence application based on a number of risk factors. If the CNSC requires additional information at this point, it will ask for it from the applicant. Additional information requested may be related to quantity, technical specifications of the item(s) or more information about the end-use or end-user. The CNSC will resume processing the application when it receives the requested information from the applicant.

When assessing an application, the CNSC considers a range of information, such as:

- the non-proliferation credentials of the importing country (whether it is a member of the NPT and/or NSG)

- information available with regard to nuclear weapons-related activities in the end-user country or an intermediary country (if any)

- the applicability of bilateral NCAs

- relevance of the items in question to any known procurement efforts

- risk of diversion posed by the transfer

- utility of the item(s) to a nuclear weapon or nuclear explosive device

- any proliferation concerns regarding any parties to the transaction

- whether the end-use and end-user are legitimate

- previous denials to a certain end-user

- the types of assurances or guarantees provided and/or required

The CNSC will assess the overall proliferation risk, taking into account all of the above factors, for each application. Examples of some of the specific areas that are assessed are considered below.

Whether the item is controlled by the Nuclear Non-proliferation Import and Export Control Regulations

The CNSC will review the description of the item to determine if the item is controlled under the NNIECR. If it is deemed that the item is not controlled, the applicant will be informed in writing (by email or letter) of this decision. If, on the basis of the information already provided in the application, the control status is unclear, the CNSC will request further information from the applicant as per subsection 3(2) of the NNIECR.

Intangible technology transfers

Export controls also apply to intangible transfers of controlled nuclear information; for example, in the case of controlled nuclear information (see A.4 and B.3 in Appendix E). Examples of intangible transfers include:

- emails

- face-to-face meetings

- telephone conversations

- provision of services or training

- publishing in international journals or exchanging information in international forums

- downloads or other electronic file exchanges

Intangible transfers still require export authorization.

This includes the transfer of controlled nuclear information to and from a cloud service provider when those servers are located outside of Canada.

If uncertain as to whether an import or export licence is required, there is no cost associated with submitting an application for assessment. Alternatively, applicants are encouraged to contact the CNSC at export-import@cnsc-ccsn.gc.ca.

Whether the item is subject to a nuclear cooperation agreement

If the item is controlled and found to be subject to an NCA, the appropriate bilateral notifications must be exchanged with the country that will import the item. Depending upon the partner country, this step usually takes from one to six weeks. In general, items found in Part A of Appendix E are subject to an NCA.

Country of origin of the item

Applicants are to identify the origin of the item in the application, so the CNSC can determine what bilateral commitments, if any, are associated with the item.

End-use and end-user

With export applications in particular, a large part of the CNSC’s assessment focuses on whether the end use and end-user are legitimate, as well as whether the transfer poses a proliferation risk.

If the item is not subject to an NCA, the recipient country is not bound by the same level of obligations that help to minimize the proliferation risk associated with the international transfer of major nuclear items.

In the case of nuclear-related dual-use items (see Part B of Appendix E), it is also necessary to determine if end-use assurances are required.

Open-source information may be used to assess the end-use and end-user, in order to ensure they are consistent with the items being transferred and that the transfer is solely for peaceful uses. In some cases, it may be necessary to obtain further assistance and information from other government departments.

Other regulatory considerations

Depending on the item, an application may be forwarded to other divisions within the CNSC for review. This ensures that other CNSC requirements related to safeguards, security (Nuclear Security Regulations), packaging and transport of nuclear substances (Packaging and Transport of Nuclear Substance Regulations), waste management, and possession controls are considered before import and export licences are issued.

6.3 Decision of the designated officer

CNSC staff review the application and make a recommendation to the designated officer. The decision whether or not to issue the import or export licence is made by the designated officer in consideration of subsection 24(4) of the NSCA.

If the designated officer is considering denying the application, the applicant will be informed of this via a formal letter. Under paragraph 39(1)(a) of the NSCA, the designated officer shall provide a reasonable opportunity to be heard to the applicant before refusing to issue a licence. As such, the letter identifies the opportunity for the applicant to submit any additional information that they believe the designated officer should consider. The letter also provides time limits for filing additional information with the designated officer and instructions for submitting the information. Rule 27 of the Canadian Nuclear Safety Commission Rules of Procedure applies with respect to the opportunity to be heard.

Should the designated officer refuse to issue a licence, the applicant can appeal the designated officer’s decision to the Commission. Subsection 43(1) of the NSCA and Rules 29 and 30 of the Canadian Nuclear Safety Commission Rules of Procedure apply with respect to a licence appeal.

7. End-Use Controls for Nuclear-Related Dual-Use Items

End-use controls, also known as "catch-all" controls, allow the CNSC to control items that are not otherwise specifically listed in the Appendix E when there are reasonable grounds to believe that such items may be intended for use in connection with a nuclear weapons program.

These less sensitive items do not meet the technical specifications of the items listed in Part B of Appendix E, but may still be of use in a nuclear weapons program. Examples include items used in the development and infrastructure of a nuclear weapons program, such as research and development programs at universities or unsafeguarded civilian nuclear reactors. As a result, such items may require a licence if there are reasonable grounds to suspect the item is intended for use in a nuclear weapons program. The end-use controls in Appendix E apply to substances (paragraph B.1.1.20), equipment (paragraph B.2.7.6) and information (paragraph B.3).

7.1 Why end-use controls are necessary

The items listed in the Appendix E are based on lists of nuclear and nuclear-related dual-use items agreed to by the NSG. The lists capture only the most proliferation-sensitive items, since the inclusion of all possible (less-sensitive) items that might support a nuclear weapons program would create an unnecessary burden on legitimate trade. End-use controls help the CNSC ensure that Canadian exporters do not contribute knowingly or unwittingly to a nuclear weapons program, by requiring less sensitive items to be made licensable if they are – or may be – for use in a nuclear weapons program.

7.2 When end-use controls are applied

The CNSC determines if the end-use control is applicable upon receipt of an enquiry or application from the exporter, or if it determines that a shipment is being made to an end-user of concern. The latter determination may be accomplished through information received by the CNSC, or if the Canada Border Services Agency (CBSA) detains a shipment and consults with the CNSC as to whether an export licence is required.

When the end-use control is applicable, the exporter will be informed by letter or email that an export licence is required before the item(s) may be exported. Once an export application is submitted, it will be assessed using the approach described in section 6 of this document. If the assessment concludes there is no risk of the item being used in, or diverted to, a nuclear weapons program, a licence will be issued. If CNSC staff recommend refusing the issuance of a licence, the aforementioned process for licence refusal will apply.

7.3 What exporters have to do

If an export is subject to end-use controls, the exporter should contact the CNSC and apply for a licence. An export is likely to be controlled if it is known or suspected that it will be used in connection with the design, development, production, handling, operation, maintenance or storage of nuclear weapons or other nuclear explosive devices.

Exporters may often be unable to recognize, or may be unsure, if their products are intended for illicit purposes, e.g., in a nuclear weapons program. Appendix A therefore provides guidance to help exporters identify suspicious enquiries or orders that could require greater scrutiny.

If exporters are uncertain whether end-use controls apply to an export, they may:

- contact the CNSC at export-import@cnsc-ccsn.gc.ca to request further information

- submit an export licence application

8. Compliance With CNSC Requirements

With respect to the import and export of controlled nuclear substances, equipment and information, individuals and companies are required to comply with the NSCA, its regulations, licences and their terms and conditions, as well as any orders made under the NSCA.

8.1 How the CNSC verifies compliance

The CNSC conducts activities to verify and promote compliance, with the objective of assuring Canadians and the international community that international transfers of nuclear and nuclear related dual-use items are used only for peaceful, non-explosive purposes. Audits of licence conditions and inspection activities are among the ways that the CNSC verifies compliance with import and export licences.

Audits of licence conditions

Subsection 24(5) of the NSCA allows licences to contain any term or condition that the CNSC considers necessary for meeting the purposes of the Act. Like other licences issued by the CNSC, import and export licences contain terms and conditions with which the licensee must comply. The conditions included within a licence depend on the nature of the item(s) being imported or exported and are generally related to:

- prior or post shipment notifications

- monthly or annual reporting

- action to be taken with respect to the CBSA in relation to section 18 of the GNSCR

The CNSC reviews the information provided by licensees to verify that the authorized quantity of the licence has not been exceeded and that, in the case of export licences, items are only being exported to authorized end-users. The CNSC also reviews the information provided as part of prior or post shipment notifications to verify that exports are being made in accordance with the terms and conditions of licences.

Inspection activities

The CNSC uses two general types of inspection activities to verify compliance with import and export licences:

- The first is an audit of import/export-related documentation at licensees’ facilities. CNSC inspectors may review information such as shipping-related documentation, CBSA customs declarations and inventory control documents.

- The second is an inspection of goods that have been detained at the border by the CBSA, in order to determine if they require a CNSC export licence.

The documents required during CNSC audits of electronic transfers of controlled nuclear information will be case-dependent. A licensee is expected to have a clear understanding of when controlled nuclear information is being transferred, regardless of how it is transferred. For example, if the licensee is sending controlled nuclear information by email, that email should be associated with the requisite licence and should be easily identifiable to the licensee. This will allow for a record of the controlled nuclear information that has been transferred.

Depending on the type of information being transferred, controlled nuclear information may or may not be associated with a formal inventory control system. Regardless of the system employed or the way in which controlled nuclear information is transferred, when controlled nuclear information is transferred it should be easily identifiable to the licensee and done in a manner in which records can be provided to the CNSC. The CNSC advises that documents be retained for a six year period.

8.2 Disclosure of non-compliance

The CNSC recognizes that responsible importers and exporters may, on occasion, inadvertently fail to obtain the appropriate import or export authorization from the CNSC, as required under the NSCA. Similarly, they may unintentionally fail to comply with a condition of an import or export licence. Importers and exporters in such a situation are encouraged to disclose any incidence of non-compliance to the CNSC as soon as possible. Appendix B sets out the recommended disclosure procedures to be followed in case of non-compliance.

The CNSC looks favourably upon disclosures if, after considering the information provided (including the nature and seriousness of the disclosed violation or omission), it is satisfied that the importer or exporter has fully cooperated and taken appropriate measures to prevent future re-occurrence of non-compliance. In such instances, no further action is generally warranted.

If no disclosure is made, the CNSC may consider various options to address non compliance, depending on the gravity of the incidence of non-compliance or on the overall circumstances. One such option is to issue an administrative monetary penalty, which is a monetary penalty imposed without court involvement for the violation of a regulatory requirement (see the CNSC’s website for more information). More serious cases may be referred to the CBSA or the RCMP for further review or investigation.

8.3 Best practices for responsible exporters

Further information on best practices for responsible exporters can be found in a document published on the NSG website. Good Practices for Corporate Standards to Support the Efforts of the International Community in the Non-Proliferation of Weapons of Mass Destruction offers suggestions that are not legally binding and that aim to boost commercial-sector support for non-proliferation by reducing the risk of inadvertent supply of items to illicit procurement programs.

Another example of best practices, focused on vendors, is the Nuclear Power Plant Exporters’ Principles of Conduct.

Part II: Risk-Significant Radioactive Sources

9. Program Framework

9.1 Overview

This section outlines the basis for import and export controls implemented by the CNSC for risk-significant radioactive sources (Category 1 and 2 radioactive sources).

The CNSC’s export and import control program for risk-significant radioactive sources includes consideration of Canada’s political commitment to adopt two key International Atomic Energy Agency (IAEA) documents: the Code of Conduct on the Safety and Security of Radioactive Sources (the Code) and the Guidance on the Import and Export of Radioactive Sources (the Guidance). Under the leadership of the IAEA, the Code and the Guidance were developed by the international community to augment the safety and security of radioactive sources. The Government of Canada has committed to implement the provisions contained within the Code, including implementing export and import controls consistent with the Code and Guidance.

9.2 The domestic context

As Canada’s nuclear regulatory authority, the CNSC is responsible for controlling the export and import of risk-significant radioactive sources. Through its role in implementing export and import control measures, the CNSC enhances national and international safety and security by ensuring that only authorized persons are recipients of risk-significant radioactive sources. The CNSC’s program is consistent with the Code and Guidance, which have the following objectives:

- achieving a high level of safety and security regarding risk-significant radioactive sources

- reducing the likelihood of accidental harmful exposure to risk-significant radioactive sources or the malicious use of such sources to cause harm to individuals, society and the environment

- mitigating or minimizing the radiological consequences of any accident or malicious act involving risk-significant radioactive sources

9.3 The international context

Implementation of radioactive source export and import controls consistent with the Code and Guidance requires cooperation and consultation between regulatory authorities in the exporting and importing countries. The CNSC may enter into bilateral administrative arrangements with regulatory authorities in countries with which Canada has trade in risk-significant radioactive sources and with countries that share Canada’s commitments to effective international controls on transfers of radioactive sources. The objective of these arrangements is to establish harmonized bilateral procedures and communication channels for the efficient implementation of export and import controls, and thus to reduce the risk of undue delays in regulatory authorizations.

10. Risk-Significant Radioactive Sources

Risk-significant radioactive sources correspond to Category 1 and 2 radioactive sources of the IAEA’s categorization of radioactive sources (IAEA RS-G-1.9 – Categorization of Radioactive Sources). Table 1 lists the isotopes and threshold activities in Terabecquerels (TBq) for the Category 1 and Category 2 radioactive sources requiring export authorizations. Category 1 and Category 2 radioactive sources are defined as risk-significant radioactive sources for the purpose of the CNSC export and import control program.

Table 1: Threshold Activities for Category 1 and Category 2 Radioactive Sources

| Nuclear Substance | Category 1 (TBq) | Category 2 (TBq) |

|---|---|---|

| Americium-241 | 60 | 0.6 |

| Americium-241/Beryllium | 60 | 0.6 |

| Californium-252 | 20 | 0.2 |

| Curium-244 | 50 | 0.5 |

| Cobalt-60 | 30 | 0.3 |

| Cesium-137 | 100 | 1.0 |

| Gadolinium-153 | 1,000 | 10.0 |

| Iridium-192 | 80 | 0.8 |

| Promethium-147 | 40,000 | 400.0 |

| Plutonium-238 | 60 | 0.6 |

| Plutonium-239/Beryllium | 60 | 0.6 |

| Radium-226 | 40 | 0.4 |

| Selenium-75 | 200 | 2.0 |

| Strontium-90 (Yttrium-90) | 1,000 | 10.0 |

| Thulium-170 | 20,000 | 200.0 |

| Ytterbium-169 | 300 | 3.0 |

11. Licensing and Control Process

11.1 Overview

The CNSC export and import control program for risk-significant radioactive sources is designed to meet the provisions of the IAEA Code and the Guidance, in addition to the regulatory requirements under NSCA. Key elements of this regulatory program include:

- a licensing and compliance process for the export of risk-significant radioactive sources

- a control process for the import of risk-significant radioactive sources

- implementation of bilateral administrative procedures with foreign regulatory authorities

11.2 Export licensing

A CNSC licensee authorized to use or possess a risk-significant radioactive source must apply for and be issued an export licence before exporting that source. The licensee must ensure the information provided in an application is comprehensive enough to enable the CNSC to evaluate effectively the request for authorization to export. The CNSC assesses the information provided by the applicant to ensure that the proposed export meets national requirements and international obligations. For Category 1 radioactive source exports, the CNSC consults with the Importing State Authority prior to completing the assessment of an application.

Export licences may contain any term or condition considered necessary for the purpose of the Nuclear Safety and Control Act, including requirements for providing prior and post shipment notifications of shipments.

11.3 Import controls

The CNSC typically does not issue specific licences for the import of risk-significant radioactive sources. CNSC licensees that are authorized to possess risk-significant radioactive sources may import such sources consistent with the general import authorization for those sources that exists in their possession licences.

The CNSC implements additional regulatory compliance controls on imports of risk-significant radioactive sources to ensure that bilateral responsibilities required under the Code and Guidance are met. These compliance controls include the review of prior import notifications received from foreign exporters, and decisions on requests received from foreign regulators (Exporting State Authority) for CNSC consent to the import of Category 1 radioactive sources.

11.4 How to apply for a CNSC export licence

Applicants for an export licence must hold a licence issued by the CNSC to possess the risk-significant radioactive sources in question.

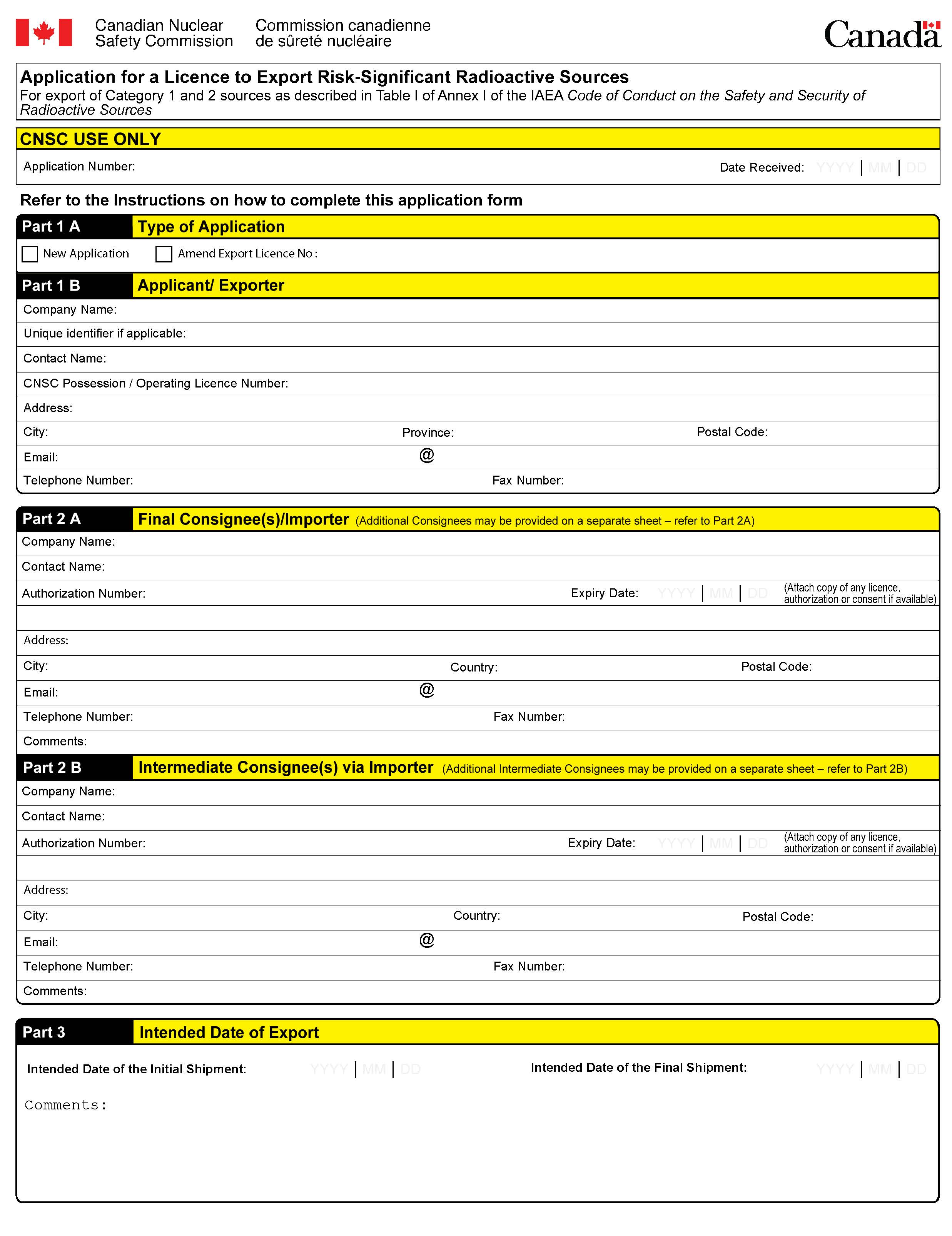

The CNSC has developed an application form for export licences (Application for a Licence to Export Risk-Significant Radioactive Sources). Appendix D of this document provides detailed information on completing the application form, and also includes a copy of the form for reference in Appendix D.1.

Unless otherwise authorized by the CNSC:

- a separate application is required for each export transaction or specific set of transactions that are anticipated to occur within a specific period of time

- each export licence issued will authorize transfers to one or more recipients, but only to a single country

- separate export licences will be issued for Category 1 and Category 2 radioactive sources

Each transaction may involve multiple shipments carried out over a specified period of time.

Completed export licence applications should be submitted to the CNSC’s Licensing Administrator (Radioactive Sources), via mail, fax or email:

Licensing Administrator (Radioactive Sources)

Non-Proliferation and Export Controls Division

Directorate of Security and Safeguards

Canadian Nuclear Safety Commission, P.O. Box 1046, Station B

280 Slater Street, Ottawa, ON K1P 5S9

Fax: 613-995-5086

Email: export-import@cnsc-ccsn.gc.ca

11.5 Licence amendments and transfers

A CNSC export licence may be amended to:

- change the expiry date

- add or remove consignees

- add or remove items authorized for export

- change the sender or recipient address

- change the quantity of items on the existing licence

- modify the end-use

To request a licence amendment, use the application forms referenced in Appendix D.1 of this document. Select the "Amendment Export Licence No" box and complete the relevant section(s) of the application form.

Please note: A licence cannot be amended once the authorized quantity has been exported. Similarly, an amendment cannot be made after a licence has expired. Therefore, applications to amend licences should be received by the CNSC at least 15 business days before the amended licence is required. The transfer of a CNSC export licence from an existing licensee (the transferor) to another entity (the transferee) may be authorized by the CNSC upon consideration of an application submitted by both entities. Licence transfers may be authorized where a change of legal status has occurred and it can be verified that the new licensee (the transferee) is capable of ensuring compliance with the NSCA, relevant regulations and all licence conditions. If significant changes to the terms and conditions are also proposed, a transfer will not be authorized and the applicant for the licence will need to apply for issuance of a new licence. Further information can be obtained by contacting the CNSC’s Licensing Administrator (Radioactive Sources).

11.6 Processing time and service standards

Applicants can generally expect the CNSC to decide upon the issuance of an export licence within 15 business days of receiving a complete application. Incomplete applications cannot be processed, and additional information will be required before the assessment can proceed.

While the CNSC strives to process all applications within 15 business days, the time required for processing an application for an export licence is affected, in part, by the scope of international communications and consultations that are required. The length of time for completing these will depend on a variety of factors, such as the state of the importing country’s regulatory infrastructure for the control of radioactive sources, the availability of information on the end-user, and whether the export item is a Category 1 or Category 2 source. As a result, additional time may be required in some cases to process an export licence application. Applicants are always encouraged to apply for an export licence at the earliest opportunity.

The CNSC website provides more information on service standards for import and export licences.

12. Evaluation of Licence Applications

12.1 Receipt of the application

Upon receipt of an export licence application, the CNSC sends an email of acknowledgement to the applicant. This acknowledgement message assigns a reference number to the application, which both the applicant and the CNSC should use in any future correspondence.

The CNSC screens the application to ensure that all information required in the application has been submitted by the applicant. If any information is missing, the CNSC will ask the applicant to submit it.

Note: This initial screening does not consider the quality of an application or its technical aspects.

12.2 Assessment of application

The assessment of the application to export risk-significant radioactive sources involves, but is not limited to:

- review of risk associated with the end-user and consignees involved in the transfer to provide assurances that the sources will not be diverted for malicious purposes. Open source and classified information may be used in this determination

- review of the regulatory capability of the Importing State to provide assurances that the sources will be managed safely and securely

- obtaining import consent from the Importing State Authority for all applications to export Category 1 radioactive sources from Canada to further verify the end-users’ authority to receive and possess the sources

12.3 Decision of the designated officer

CNSC staff review the application and make a recommendation to the designated officer. The decision whether or not to issue the export licence is made by the designated officer pursuant to subsection 24(4) of the NSCA.

If the designated officer is considering denying the application, the applicant will be informed of this via a formal letter. Under paragraph 39(1)(a) of the NSCA, the designated officer shall provide a reasonable opportunity to be heard to the applicant before refusing to issue a licence. As such, the letter identifies the opportunity for the applicant to submit any additional information that they believe the designated officer should consider. The letter also provides time limits for filing additional information with the designated officer and instructions for submitting the information. Rule 27 of the Canadian Nuclear Safety Commission Rules of Procedure applies with respect to the opportunity to be heard.

Should the designated officer refuse to issue a licence, the applicant can appeal the decision to the Commission. Subsection 43(1) of the NSCA and Rules 29 and 30 of the Canadian Nuclear Safety Commission Rules of Procedure apply with respect to a licence appeal.

13. Compliance with CNSC Requirements

With respect to the export of risk-significant radioactive sources, individuals and companies are required to comply with the NSCA, its regulations, licences and their terms and conditions, as well as any orders made under the NSCA.

13.1 How the CNSC verifies compliance

The CNSC conducts activities to verify and promote compliance. Audits of licence conditions and inspection activities are among the ways that the CNSC verifies compliance with export licences.

Audits of licence conditions

Subsection 24(5) of the NSCA allows licences to contain any term or condition that the CNSC considers necessary for meeting the purposes of the Act. Like other licences issued by the CNSC, export licences contain conditions with which the licensee must comply. The conditions included within a licence are:

- prior and post shipment notifications

- action to be taken with respect to the CBSA in relation to section 18 of the GNSCR

The CNSC reviews the information provided by licensees to verify that the authorized quantity of the licence has not been exceeded. The CNSC also reviews the information provided as part of prior and post shipment notifications to verify that exports are being made in accordance with the terms and conditions of licences.

Inspection activities

The CNSC uses two general types of inspection activities to verify compliance with export licences:

- The first is an audit of export-related documentation at licensees’ facilities. CNSC inspectors may review information such as shipping-related documentation, CBSA customs declarations and inventory control documents.

- The second is an inspection of goods that have been detained at the border by the CBSA, in order to determine if they require a CNSC export licence.

13.2 Disclosure of non-compliance

The CNSC recognizes that responsible exporters may, on occasion, inadvertently fail to obtain the appropriate export authorization from the CNSC, as required under the NSCA. Similarly, they may unintentionally fail to comply with a condition of an export licence. Exporters in such a situation are encouraged to disclose any incidence of non-compliance to the CNSC as soon as possible. Appendix B sets out the recommended disclosure procedures to be followed in case of non-compliance.

The CNSC looks favourably upon disclosures if, after considering the information provided (including the nature and seriousness of the disclosed violation or omission), it is satisfied that the exporter has fully cooperated and taken appropriate measures to prevent future re-occurrence of non-compliance. In such instances, no further action is generally warranted.

If no disclosure is made, the CNSC may consider various options to address non compliance, depending on the gravity of the incidence of non-compliance or on the overall circumstances. One such option is to issue an administrative monetary penalty, which is a monetary penalty imposed without court involvement for the violation of a regulatory requirement (see the CNSC’s website for more information). More serious cases may be referred to the CBSA or the RCMP for further review or investigation.

Appendix A: Examples of Possible Suspicious Inquiries or Orders

The following examples illustrate some situations that could be suspicious. Importers or exporters should consider contacting the CNSC at export-import@cnsc-ccsn.gc.ca or applying for an export licence if they find themselves in these or similar circumstances:

- The customer is new and knowledge about them is incomplete or inconsistent.

- The customer is reluctant to provide information about the end-use of the item or refuses to provide an end-use statement. If information is provided, it is vague.

- The customer is unfamiliar with the item and its capabilities but still wishes to purchase the item.

- The item does not fit with the customer’s area of business. An unconvincing explanation is given as to why the items are required, given the customer’s normal business or the technical sophistication of the items.

- The customer is evasive or is reluctant to indicate whether the item is for domestic use, export or for re-export.

- The item is incompatible with the technical level of the destination country.

- The customer is willing to pay cash for an item that normally requires financing or offers to pay a higher price. Other examples of unusual payment terms are roundabout wire transfers, late changes in deal terms and/or source of payment.

- Routine installation, training or maintenance services are declined.

- The customer makes requests for excessive spare parts or displays no interest in any spare parts.

- The customer requests that the item be transferred to a forwarding address in Canada.

- A freight forwarding company is listed as the final destination.

- Unusual shipping, packaging or labelling arrangements are requested.

Appendix B: Disclosure of Non-Compliance

Any voluntary disclosure of non-compliance should be accompanied by a cover letter, signed by a senior company officer, which clearly states that its purpose is to disclose non-compliance with the Nuclear Safety and Control Act, Nuclear Non-proliferation Import and Export Control Regulations, or import and export licences. The letter should be addressed to:

Director, Non-Proliferation and Export Controls Division

Directorate of Security and Safeguards

Canadian Nuclear Safety Commission

P.O. Box 1046, Station B

280 Slater Street

Ottawa, Ontario

K1P 5S9

The following information should be included in the cover letter or in the accompanying documentation:

- details of the items concerned (including technical specifications for assessment of export control status)

- end-use of the item(s)

- dates of all shipments, mode of transport, and port of exit/entry

- quantities and values of each shipment for each product concerned (including copies of the customs declaration documents submitted to the CBSA, as well as copies of bills of lading, freight forwarding, shipping or commercial invoices)

- contract of sale between the exporter and the final consignee

- for each import/export in question, a statement as to whether the shipment took place intentionally

- description of the circumstances underlying each import/export

- description of the steps taken or processes and procedures put in place to ensure that where required, CNSC import/export licences will be obtained in the future

- any other documentation that the importer/exporter believes is relevant to the purpose of the disclosure

For more information or to inquire further about how to disclose non-compliance, contact the Canadian Nuclear Safety Commission’s Non-Proliferation and Export Controls Division via the point of contact provided in section 5.2 of this document.

Appendix C: How to Complete Import and Export Applications for Nuclear and Nuclear-Related Dual-Use Items

Applicants must complete the Application for a Licence to Import Nuclear Items (see section C.1), the Application for a Licence to Export Nuclear and Nuclear-Related Dual-Use Items (see section C.2), or the Application for a Licence to Export Risk-Significant Radioactive Sources (see section C.3), as appropriate. For more information, contact the CNSC’s Licensing Administrator (Nuclear) as outlined in section 5.2 of this document.

Ensure that information provided on the forms and in any supporting documentation is clear, accurate and complete. Attachments must specify to which section of the application they pertain. The beginnings of both forms include a check-box section that requires applicants to identify the type of request. Applicants must mark the relevant box to indicate if the application is for:

- a new licence

- a licence amendment (indicate the licence to be amended)

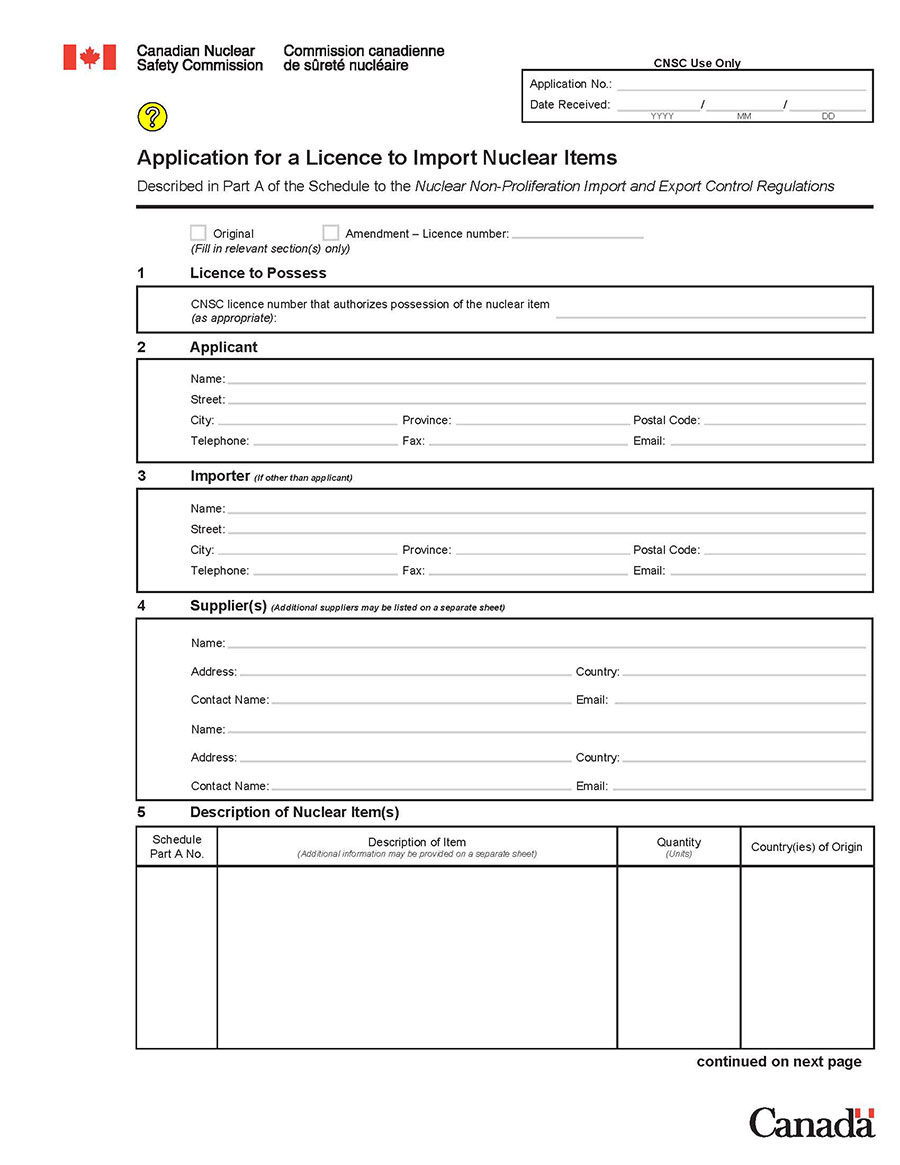

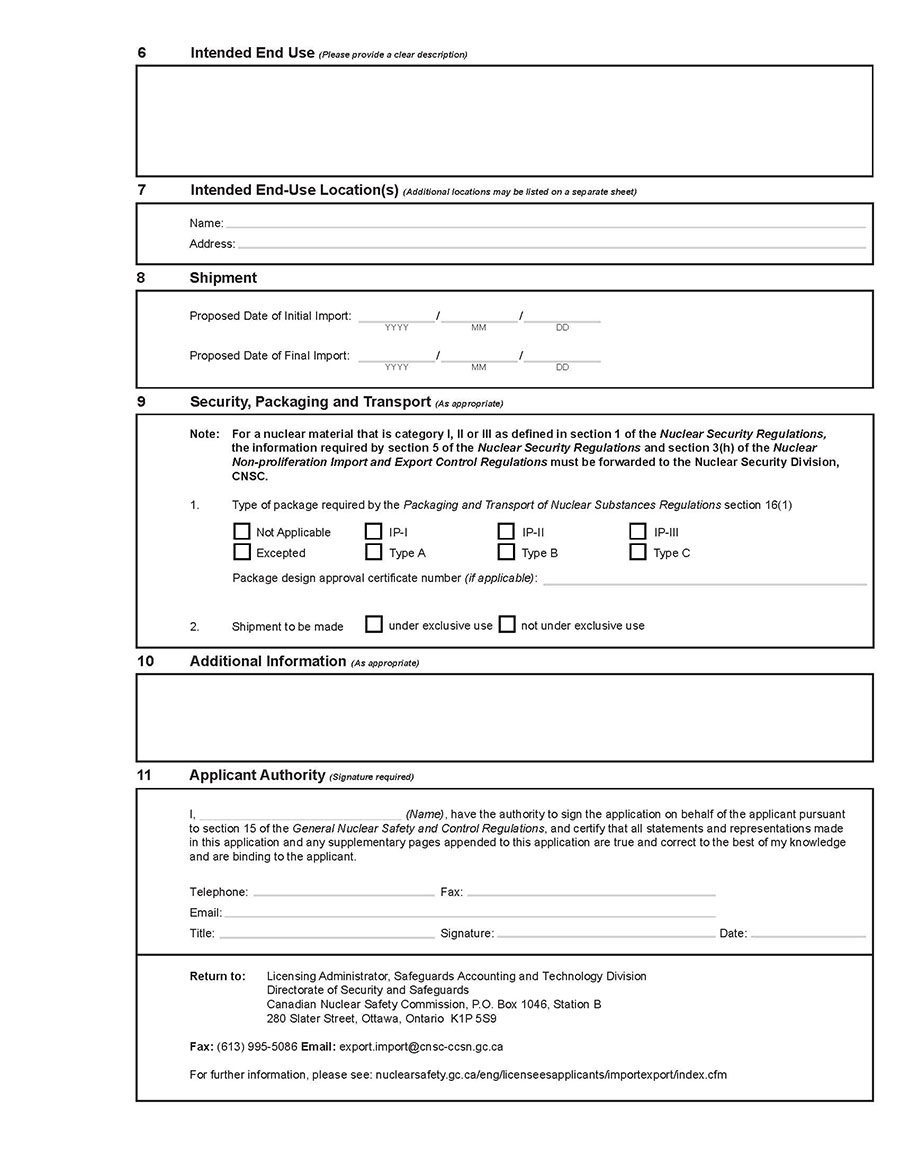

C.1: Import licence application guidance

Section 1 – Licence to Possess

As appropriate, include the number of any relevant CNSC-issued licences, such as possession, operating or facility licence.

Section 2 – Applicant

Provide the name of the person or organization applying for the licence.

Section 3 – Importer

Refers to the facility/entity in Canada that will be receiving the item(s), if not the same as the applicant. If the importing facility is not the same as the applicant, the importing facility’s name and location will appear on the licence as "Recipient Location".

Section 4 – Supplier(s)

State the foreign entity or entities that will be supplying the item(s) to the importer. Additional suppliers may be listed on a separate sheet.

Section 5 – Description of Nuclear Item(s)

Refer to Appendix E to help identify where (i.e., Part A or Part B) the item(s) is (are) controlled. Provide a brief description of the controlled items(s), including relevant technical specifications, form (liquid/solid/gas) and the exact quantity being imported. List the country or countries of origin of the item(s).

Section 6 – Intended End-Use

Describe the end-use of the item, i.e., for what will it be used?

Section 7 – Intended End-Use Location(s)

Identify the location where the item(s) will be used as per the description in section 6 of the application.

Section 8 – Shipment

Provide the anticipated dates for the initial and final imports. If only one item is being received, these dates will be the same.

Section 9 – Security, Packaging and Transport

This section applies only to nuclear material (plutonium, uranium, thorium).

Refer to the Nuclear Security Regulations to determine if the nuclear material is Category I, II, or III and, as appropriate, follow the directions provided in these regulations.

Refer to the Packaging and Transportation of Nuclear Substances Regulations, 2015 to determine what type of packaging, if any, the item(s) will require.

Exclusive use is defined by the Advisory Material for the IAEA Regulations for the Safe Transport of Radioactive Material, paragraph 221.

Section 10 – Additional Information

Provide any further information, as appropriate, in support of the application.

Section 11 – Applicant Authority

This section is to be completed and signed by the applicant or their authorized representative. The signatory must have the authority to sign the licence application and certify that all statements and representations made in the application are true and correct to the best of the signatory’s knowledge, and that the applicant is bound to them.

C.1.1 Application for a licence to import nuclear items

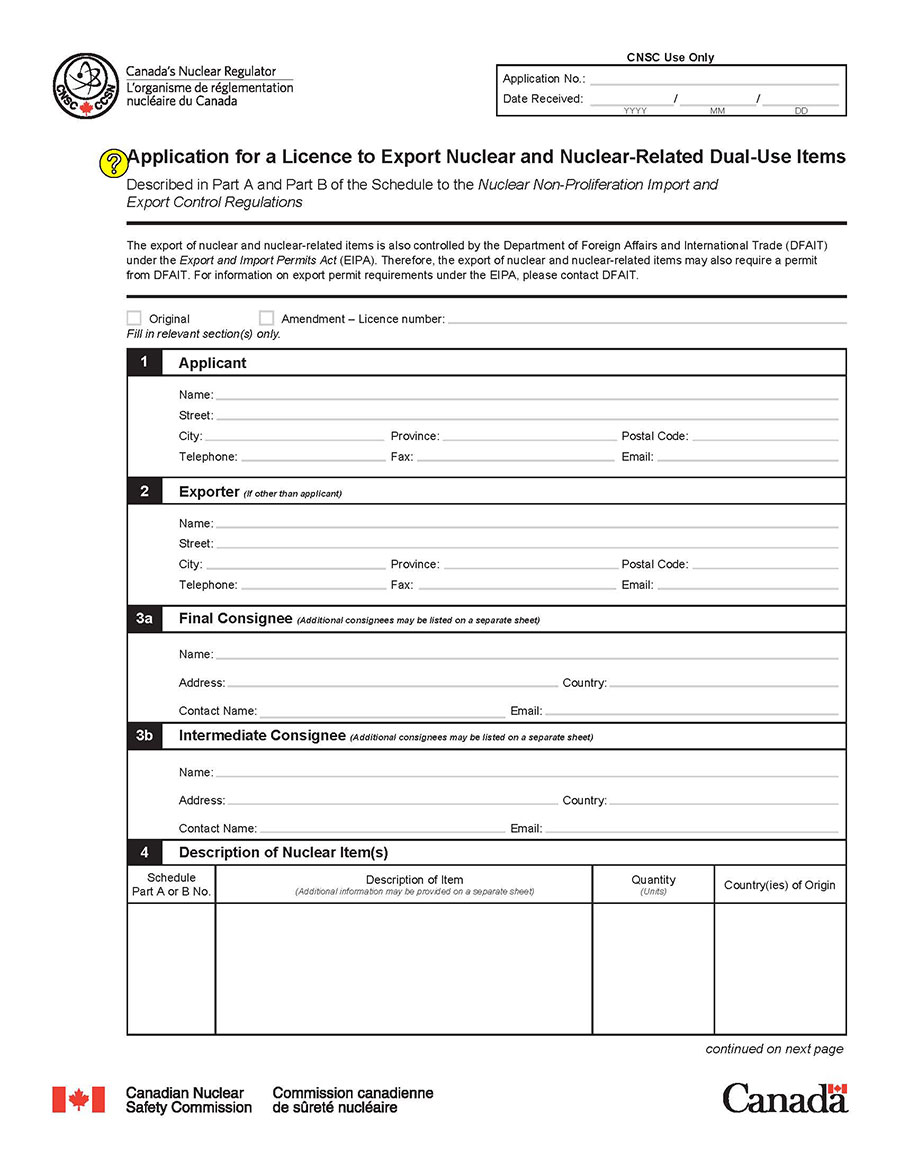

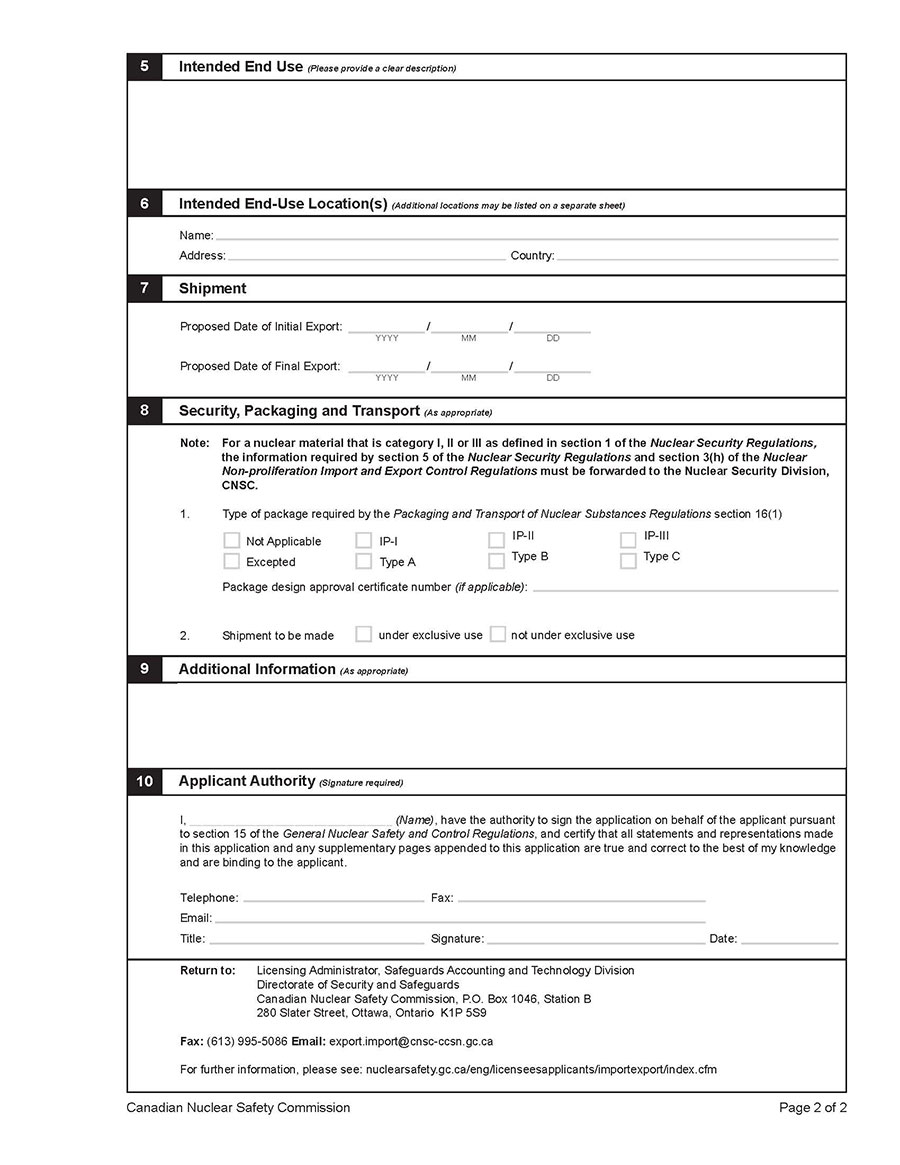

C.2: Export licence application guidance

Section 1 – Applicant

Provide the name of the person or organization applying for the licence.

Section 2 – Exporter

The exporter is the entity from whose address the item(s) will be shipped at the time of the export. If the exporter’s address differs from the applicant, this must be noted on the application.

Section 3a – Final Consignee

Refers to the final entity/facility that will receive the item(s). Note that this may be different from the final end-use location if the final consignee is receiving the item(s), but is not actually using or altering the item(s) as per the intended end-use. Additional consignees may be listed on a separate sheet.

Section 3b – Intermediate Consignee

Refers to any entity/facility that will receive the item(s) before they are delivered to the final consignee. This can occur when the entity/facility temporarily holds the item(s) prior to transfer to the final consignee/end-user. If the item(s) is directly shipped to the final consignee or end-user, this section does not apply. Additional consignees may be listed on a separate sheet.

Section 4 – Description of Nuclear Item(s)

Refer to the Appendix E to assist you in identifying where the item(s) is controlled. Provide a brief description of the controlled items(s), including relevant technical specifications, form (liquid/solid/gas) and the exact quantity being exported.

List the country or countries of origin of the item(s).

Section 5 – Intended End-Use

Describe the end-use of the item i.e., for what will it be used?

Section 6 – Intended End-Use Location(s)

Identify the location where the item(s) will be used as per the description in Section 5.

Section 7 – Shipment

Provide the anticipated dates for the initial and final exports. If only one item is being shipped, these dates will be the same.

Section 8 – Security, Packaging and Transport

This section applies only to nuclear material.

Refer to the Nuclear Security Regulations to evaluate whether the nuclear material is Category I, II, or III and, as appropriate, follow the directions provided in these regulations.

Refer to the Packaging and Transportation of Nuclear Substances Regulations, 2015 to determine what type of packaging, if any, the item(s) will require.

Exclusive use (as defined by the Advisory Material for the IAEA Regulations for the Safe Transport of Radioactive Material, paragraph 221).

Section 9 – Additional Information

Provide any further information, as appropriate, in support of the application.

Section 10 – Applicant Authority

This section is to be completed and signed by the Applicant or their authorized representative. The signatory must have the authority to sign the licence application and certify that all statements and representations made in the application are true and correct to the best of the signatory’s knowledge, and that the applicant is bound to them.

C.2.1 Application form for a licence to export nuclear and nuclear-related dual-use items

Appendix D: How to Complete an Export Application for Risk-Significant Radioactive Sources

Procedure for submitting the application

- Complete the application, sign, print and mail or fax it to the CNSC address listed at the bottom of the application form. An advance email copy may be submitted; however, a signed original must be provided.

- All mandatory information must be provided. Additional information may be submitted on a separate sheet. Incomplete applications may result in delays. Additional information or documents may be requested.

- The period to review an application is typically within 15 business days upon receipt of a completed application.

- Upon approval of the application, a licence to export risk-significant radioactive sources will be issued and sent by fax and mailed to the applicant.

D.1: Export licence application guidance

Part 1A: Type of application

Indicate if this is an application for a new licence or for an amendment to an existing export licence. If it is an amendment to an existing export licence, provide the licence number.

Part 1B: Applicant/exporter

Provide the legal name of the applicant.

Provide a unique identifier, if applicable. Applicants may input their own reference number for their tracking purposes; otherwise, it can be left blank.

Provide the name and contact information of a person that the CNSC can contact about the application.

Provide the number of the applicant's applicable CNSC possession or facility licence. This information is used by the CNSC in verifying that the applicant is authorized to possess the risk-significant radioactive source for which an export licence is sought.

Part 2A: Final consignee(s)/importer

Note: the final consignee is the one who takes possession for usage of the source.

Provide the authorization number and expiry date of the importer's authorization to receive and possess a risk-significant radioactive source. Include a copy of the authorization documentation.

If an import authorization number is unavailable, provide any additional comments or information on the final consignee or the commercial export/import arrangements that may assist the CNSC in assessing whether the source will be managed in a safe and secure manner by the final recipient of the source.

There may be multiple final consignees. Use a separate sheet and include all the information required in part 2A.

Part 2B: Intermediate consignee(s) via importer

Provide the requested information for any foreign intermediate consignee who will be in possession of the source prior to its delivery to the final consignee.

Part 3: Intended date(s) of export

Provide the date on which the export is intended to take place. If the export transaction requires multiple shipments, provide the intended date for each shipment. Where specific shipment dates are uncertain, provide anticipated initial and final dates of the shipments.

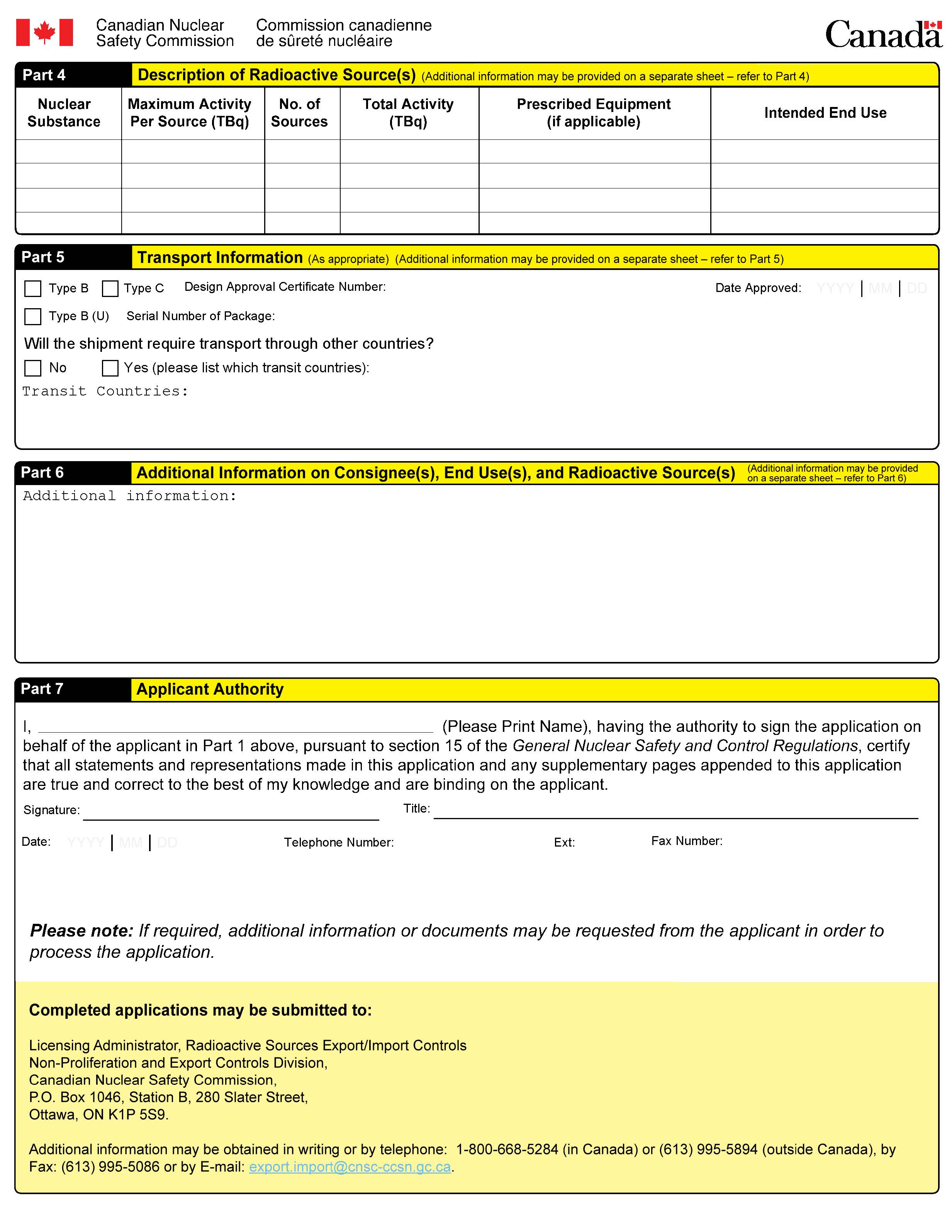

Part 4: Description of radioactive source(s)

Provide the name of the nuclear substance.

Provide the maximum activity per source (TBq), the number of sources to be exported and the total activity (TBq) of the nuclear substance to be exported.

Provide the name of any prescribed equipment that will be used with the radioactive source for the intended end use.

Describe the intended end use for each radioactive source to be exported.

Part 5: Transport information

Fill in the appropriate box to indicate what type of package is being used to transport the radioactive source.

Provide the package’s design approval certificate number and the date that the package design was approved by the CNSC.

If the prescribed equipment is a Type B(U) package – such as an industrial radiography camera – indicate the serial number of the package.

If using a Type A package, no additional information is required.

Fill in the appropriate box to indicate whether the shipment will require transport through countries other than the importing country. If yes, list the transit countries.

Part 6: Additional information on consignee(s), end use(s) and radioactive source(s)

Provide any additional information on the export transaction pertinent to supporting the application or any other details that may facilitate interactions between the CNSC and the importing authority or facility in support of completing the assessment of the application. Indicate if it is anticipated that the radioactive sources replaced by the exported sources will be returned to Canada as part of pre-existing commercial arrangements.

Part 7: Applicant authority

Provide the signature, title, telephone and fax numbers of an individual who has the authority to sign the application on behalf of the applicant, to certify the authenticity of the information in the application form and appended documents. Include the year, month, and day that the application form was signed.

D.1.1 Application form for a licence to export risk-significant radioactive sources

Appendix E: Controlled Nuclear Substances, Equipment and Information

This appendix is a copy of the current schedule that is contained in the Nuclear Non-proliferation Import and Export Control Regulations. For the most recent status, please refer directly to the regulations.

The following lists are reproduced, in rearranged form and with some modifications, from International Atomic Energy Agency Information Circulars INFCIRC/254/Rev. 12/Part.1, INFCIRC/254/Rev.9/Part.2 and INFCIRC/209/Rev.3.

PART A

LIST OF NUCLEAR ITEMS

A.1. CONTROLLED NUCLEAR SUBSTANCES

A.1.1. Special fissionable material, as follows:

(a) plutonium and all isotopes, alloys and compounds and any material that contains any of these substances; and

(b) uranium 233, uranium enriched in the isotopes 235 or 233 and all alloys and compounds and any material that contains any of these substances.

NOTE

Paragraph A.1.1. does not include

(a) special fissionable material occurring as contaminants in laundry, packaging, shielding, or equipment;

(b) special fissionable material used as a sensing component in instruments in quantities of four effective grams or less; or

(c) plutonium 238 that is contained in heart pacemakers.

A.1.2 Source material

The following source materials in any form, including ore, concentrate, compound, metal or alloy, or incorporated in any substance, other than medicinals, and in which the concentration of source material is greater than 0.05 weight %:

(a) uranium that contains the mixture of isotopes that occurs in nature;

(b) uranium that is depleted in the isotope 235; and

(c) thorium.

NOTE

Paragraph A.1.2. does not include

(a) source material occurring as contaminants in laundry, packaging, shielding, or equipment; or

(b) depleted uranium used as shielding for Class II Prescribed Equipment, within the meaning of section 1 of the Class II Nuclear Facilities and Prescribed Equipment Regulations, for radiation devices or for transport packaging.

A.1.3 Deuterium and heavy water

Deuterium, heavy water (deuterium oxide) and any other deuterium compound in which the ratio of deuterium to hydrogen atoms exceeds 1:5,000.

NOTE

Paragraph A.1.3 does not include

(a) deuterium contained in deuterium lamps;

(b) deuterium occurring as a contaminant in laundry or equipment; or

(c) any deuterium compound that is used for labelling purposes.

A.1.4 Nuclear grade graphite

Graphite having a purity level better than 5 ppm boron equivalent and with a density greater than 1.50 g/cm3.

A.1.5 Tritium

Tritium, tritium compounds or mixtures containing tritium in which the ratio of tritium to hydrogen by atoms exceeds 1 part in 1000 and products that contains any of these substances.

A.2. CONTROLLED NUCLEAR EQUIPMENT

A.2.1 Nuclear reactors and especially designed or prepared equipment and components therefor, including:

A.2.1.1 Complete nuclear reactors