Robotic technologies at nuclear facilities

Robotic technologies at nuclear facilities

Robotic technologies are used in a wide range of sectors, from automotive assembly lines to space exploration. Not only do robots allow the automation of processes, they also provide safety benefits, by allowing machines to perform tasks that would otherwise be highly dangerous or complex for humans to conduct using conventional means. For instance, robots can perform tasks in environments with extreme temperatures, pressures, or radiation fields, and inspect equipment in areas that are difficult to access. As a result, robotic technologies have become an indispensable resource across a wide spectrum of fields.

In Canada, the nuclear industry has decades of experience putting robotic technologies to work. Between February 2 and 4, 2016, the CNSC is co-sponsoring and participating in an international workshop. The purpose of this workshop is to inform, discuss, and assess past, present, and anticipated future uses of robotic technologies in safety applications and activities at nuclear facilities throughout the world. The workshop is designed to facilitate technical exchange of lessons learned from historic nuclear applications and experiences (e.g., Three Mile Island, Sellafield, and Fukushima Daiichi) and ongoing research.

Applications in Canada

Some of the earliest examples of robotics at work in Canada’s nuclear industry include the refuelling machines designed to load fuel into CANDU reactors. This application of robots, developed in the 1960s and perfected over the following decades, allows plant operators to load fresh fuel, reposition partially-used fuel, and remove used fuel without the need for a plant outage.

Robotic technologies also play a role in inspections: they help confirm that aging components are still safe. In 2010, a snake-arm robot nicknamed SAFIRE was developed for Ontario Power Generation’s Pickering Nuclear Generating Station. The device is used to assess the integrity of specific parts of the primary heat transport system, which transfer the heat from the reactor core to the steam generators. “This has allowed OPG to reduce worker dose and inspect parts previously considered inaccessible,” shares Greg Lamarre, Director of the Systems Engineering Division at the CNSC. Other robotic devices at Pickering include a series of crawler robots designed by Promation Nuclear, which are used for removing, cleaning or recovering radioactive materials. These technologies represent a key component in a nuclear power plant’s tool kit.

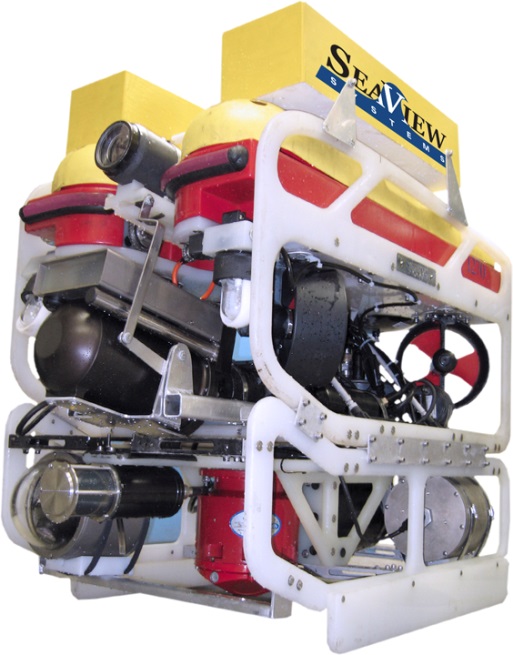

But nuclear power plants are not the only places robots are used. Following the flooding of the mine shaft of its Cigar Lake facility in 2008, Cameco contracted a company specialized in underwater operation to assist locating and plugging a broken grout line. The Seaeye Falcon DR ROV was used like a mini-submarine to navigate through frigid waters to assess the situation. The ROV was equipped with a highly sensitive thermometer to detect the source of leak even though there was virtually no visibility. The robotic device was then able to assist in the actual sealing of the leak. Today, the Cigar Lake mine is now fully operational thanks in part to robots.

Other Canadian applications include operations conducted on the Chalk River Laboratories NRU reactor. This research reactor requires constant inspections and repairs as well as long-term maintenance. All of these key functions are performed by or with the assistance of an array of robotic devices. As a result, the lifetime operations of the NRU reactor have been safely expanded.

Waste management and decommissioning

Robotic technologies also play a role as part of the decommissioning process. For instance, in the United Kingdom, robots perform tasks such as handling waste materials and dismantling equipment with precision. For roughly 20 years, trained technicians have been able to minimize their radiation exposure while managing waste and decommissioning sites.

Robots have also been used to perform reactor stabilization, inspection and cleanup activities at the Fukushima Daiichi nuclear power plant. Due to the severe nature of the accident, technicians and cleanup personnel are unable to reach some parts of the reactors. However, new robots have been designed to safely do what humans could not, and these technologies will continue to play a pivotal role in the waste management and decommissioning efforts.

Page details

- Date modified: