Regulatory Oversight Report for Nuclear Power Generating Sites: 2017

Table of contents

- Executive

- 1 Introduction

-

2 General and supporting information

- 2.1 Management system

- 2.2 Human performance management

- 2.3 Operating performance

- 2.4 Safety analysis

- 2.5 Physical design

- 2.6 Fitness for service

- 2.7 Radiation protection

- 2.8 Conventional health and safety

- 2.9 Environmental protection

- 2.10 Emergency management and fire protection

- 2.11 Waste management

- 2.12 Security

- 2.13 Safeguards and non-proliferation

- 2.14 Packaging and transport

- 2.15 Other matters of regulatory interest

-

3 Nuclear power plant and waste management facility safety performance and regulatory developments

-

3.1 Darlington site

- 3.1.0 Introduction

- 3.1.1 Management system

- 3.1.2 Human performance management

- 3.1.3 Operating performance

- 3.1.4 Safety analysis

- 3.1.5 Physical design

- 3.1.6 Fitness for service

- 3.1.7 Radiation protection

- 3.1.8 Conventional health and safety

- 3.1.9 Environmental protection

- 3.1.10 Emergency management and fire protection

- 3.1.11 Waste management

- 3.1.12 Security

- 3.1.13 Safeguards and non-proliferation

- 3.1.14 Packaging and transport

- 3.1.15 Other matters of regulatory Interest

-

3.2 Pickering site

- 3.2.0 Introduction

- 3.2.1 Management system

- 3.2.2 Human performance management

- 3.2.3 Operating performance

- 3.2.4 Safety analysis

- 3.2.5 Physical design

- 3.2.6 Fitness for service

- 3.2.7 Radiation protection

- 3.2.8 Conventional health and safety

- 3.2.9 Environmental protection

- 3.2.10 Emergency management and fire protection

- 3.2.11 Waste management

- 3.2.12 Security

- 3.2.13 Safeguards and non-proliferation

- 3.2.14 Packaging and transport

- 3.2.15 Other matters of regulatory interest

-

3.3 Point Lepreau

- 3.3.1 Management system

- 3.3.2 Human performance management

- 3.3.3 Operating performance

- 3.3.4 Safety analysis

- 3.3.5 Physical design

- 3.3.6 Fitness for service

- 3.3.7 Radiation protection

- 3.3.8 Conventional health and safety

- 3.3.9 Environmental protection

- 3.3.10 Emergency management and fire protection

- 3.3.11 Waste management

- 3.3.12 Security

- 3.3.13 Safeguards and non-proliferation

- 3.3.14 Packaging and transport

- 3.3.15 Other matters of regulatory interest

-

3.4 Bruce A and B

- 3.4.1 Management system

- 3.4.2 Human performance management

- 3.4.3 Operating performance

- 3.4.4 Safety analysis

- 3.4.5 Physical design

- 3.4.6 Fitness for service

- 3.4.7 Radiation protection

- 3.4.8 Conventional health and safety

- 3.4.9 Environmental protection

- 3.4.10 Emergency management and fire protection

- 3.4.11 Waste management

- 3.4.12 Security

- 3.4.13 Safeguards and non-proliferation

- 3.4.14 Packaging and transport

- 3.4.15 Other matters of regulatory interest

-

3.5 WWMF and RWOS-1

- 3.5.1 Management system

- 3.5.2 Human performance management

- 3.5.3 Operating performance

- 3.5.4 Safety analysis

- 3.5.5 Physical design

- 3.5.6 Fitness for service

- 3.5.7 Radiation protection

- 3.5.8 Conventional health and safety

- 3.5.9 Environmental protection

- 3.5.10 Emergency management and fire protection

- 3.5.11 Waste management

- 3.5.12 Security

- 3.5.13 Safeguards and non-proliferation

- 3.5.14 Packaging and transport

- 3.5.15 Other matters of regulatory interest

-

3.6 Gentilly-2

- 3.6.1 Management system

- 3.6.2 Human performance management

- 3.6.3 Operating performance

- 3.6.4 Safety analysis

- 3.6.5 Physical design

- 3.6.6 Fitness for service

- 3.6.7 Radiation protection

- 3.6.8 Conventional health and safety

- 3.6.9 Environmental protection

- 3.6.10 Emergency management and fire protection

- 3.6.11 Waste management

- 3.6.12 Security

- 3.6.13 Safeguards and non-proliferation

- 3.6.14 Packaging and transport

- 3.6.15 Other matters of regulatory interest

-

3.1 Darlington site

- Appendix A: Definitions of CNSC safety and control areas

- Appendix B: Darlington new build

- Appendix C: Rating definitions and methodology

- Appendix D: Research and development efforts in support of NPP regulation

- Appendix E: List of regulatory requirements at the end of 2017

- Appendix F: Revisions

- Appendix G: Five-year trends in compliance activities

- Appendix H: Current and predicted status of key parameters and models in operating reactors with older pressure tubes

- Appendix I: Derived release limits and radiological releases to the environment

- Appendix J: List of completed CNSC inspections in 2017

- Appendix K: Responsibilities and details for nuclear emergency preparedness and response

Executive summary

This report describes the regulatory oversight and safety performance of nuclear power plants (NPPs) and adjacent waste management facilities (WMFs) in Canada in 2017. For certain topics, updates on developments in 2018 are also described. This is the first CNSC regulatory oversight report to cover both NPPs and WMFs. The WMFs and the NPP at Gentilly-2 were not covered by a regulatory oversight report for 2016.

The following lists the facilities located at the same site that are governed by a single CNSC licence and assessed together in this report.

- Darlington Nuclear Generating Station (DNGS) and Tritium Removal Facility

- Darlington Waste Management Facility (DWMF) which includes the Retube Waste Storage Building

- Pickering Nuclear Generating Station (PNGS)

- Pickering Waste Management Facility (PWMF)

- Point Lepreau Nuclear Generating Station (PLGNS) and Solid Radioactive Waste Management Facility

- Western Waste Management Facility (WWMF) and Radioactive Waste Operations Site-1

- Gentilly-2 Facilities

- Bruce A Nuclear Generating Station, Bruce B Nuclear Generating Station, and the Central Laundry and Maintenance Facility are located at the same site and are also governed by a single CNSC licence. However, because of some differences in how programs are implemented at these facilities, Bruce A and Bruce B are assessed separately in this report.

The CNSC’s substantial regulatory effort for NPPs and WMFs in 2017 included activities related to licence renewals for NPPs and WMFs, and compliance verification activities such as inspections, desktop reviews, and surveillance and monitoring. The licensing decisions and compliance activities identified follow-up activities, findings and corrective actions that CNSC staff monitored during 2017. CNSC staff continue to follow up on developments and corrective actions that were not concluded by the end of 2017.

The licensing and compliance activities were conducted in the context of robust regulatory requirements. The requirements include those found in CNSC regulatory documents and CSA Group standards, which continued to evolve in 2017, as both organizations published new and revised documents. NPP and WMF licensees were in the process of implementing various new requirements in 2017, and CNSC staff were satisfied with the progress made overall.

CNSC staff concluded that the NPPs and WMFs operated safely in 2017. This conclusion was based on detailed staff assessments of findings from compliance verification activities for each facility based on the 14 CNSC safety and control areas (SCAs). The conclusion was supported by safety performance measures and other observations.

Important performance measures and observations included the following:

- The NPP and WMF licensees followed approved procedures and took appropriate corrective action for all events reported to the CNSC. No events above Level 0 on the International Nuclear and Radiological Event Scale were reported to the International Atomic Energy Agency (IAEA).

- NPPs and WMFs operated within the bounds of their operating policies and principles.

- There were no serious process failures at the NPPs. The number of unplanned transients and trips in the reactors was low and acceptable to CNSC staff. All unplanned transients in the reactors were properly controlled and adequately managed.

- Radiation doses to the public were well below the regulatory limits.

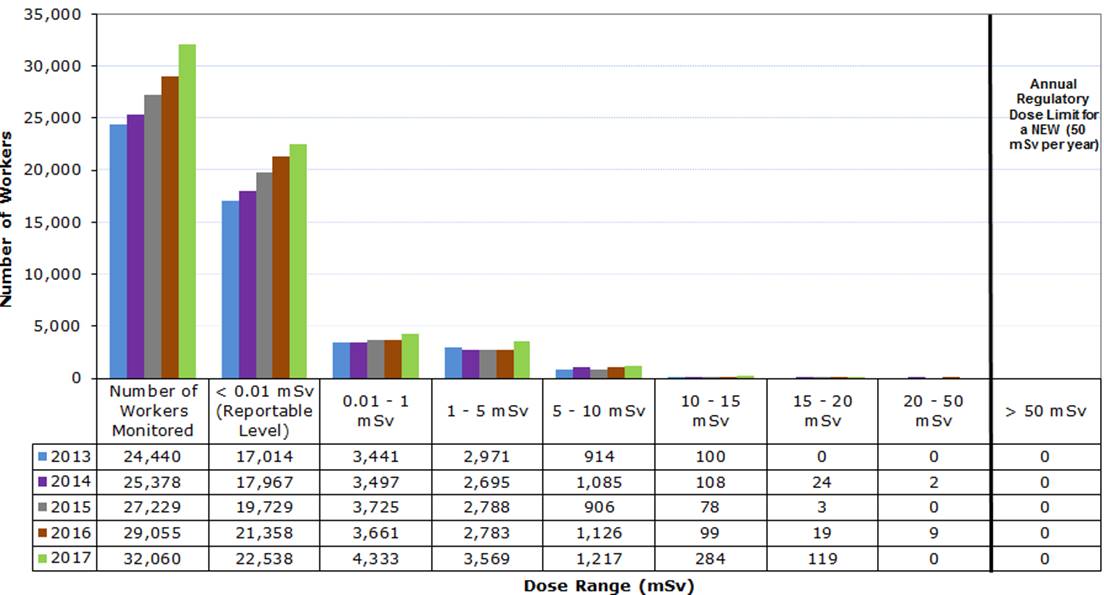

- Radiation doses to workers at the NPPs and WMFs were below the regulatory limits. The annual average effective radiation dose to workers at NPPs and WMFs remained low in 2017.

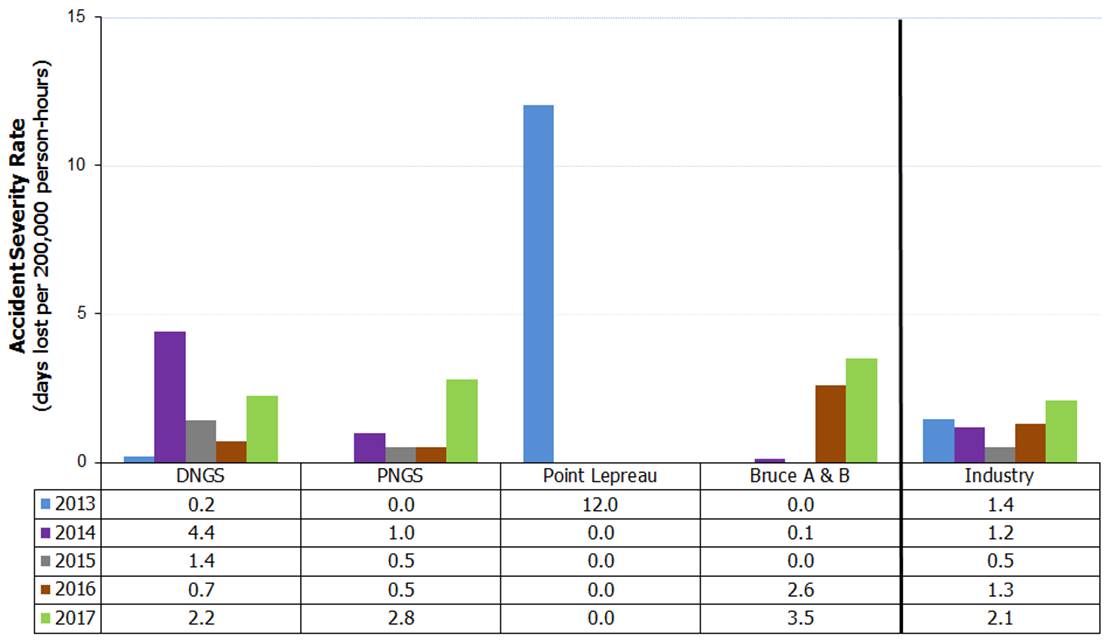

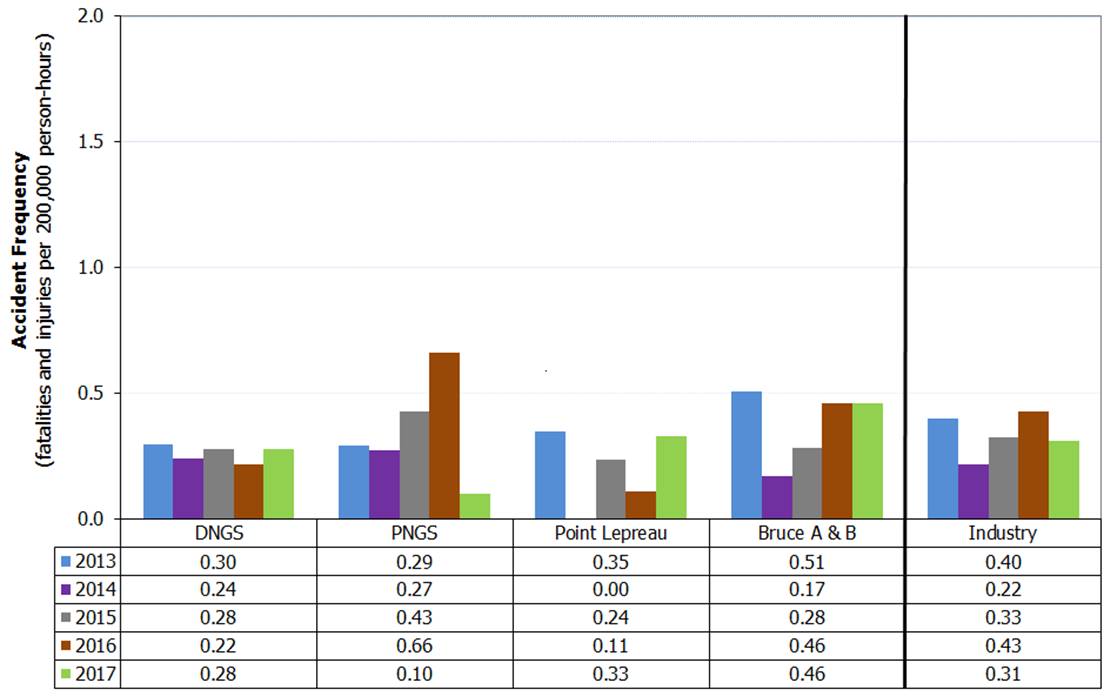

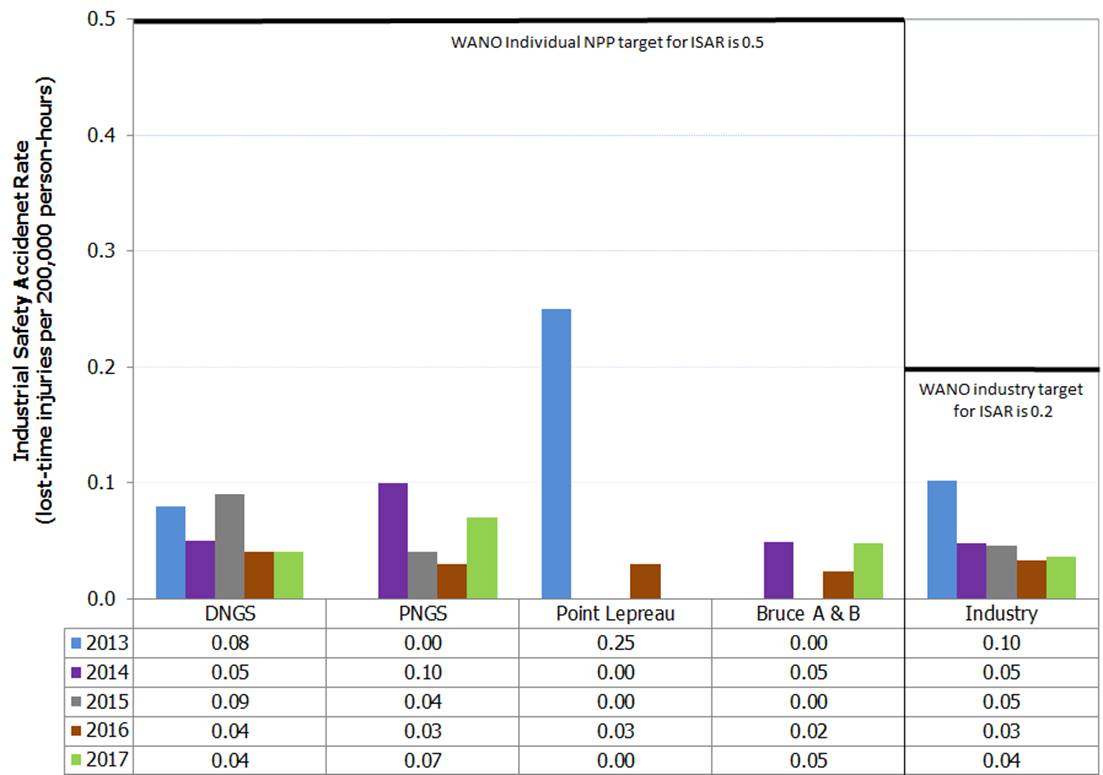

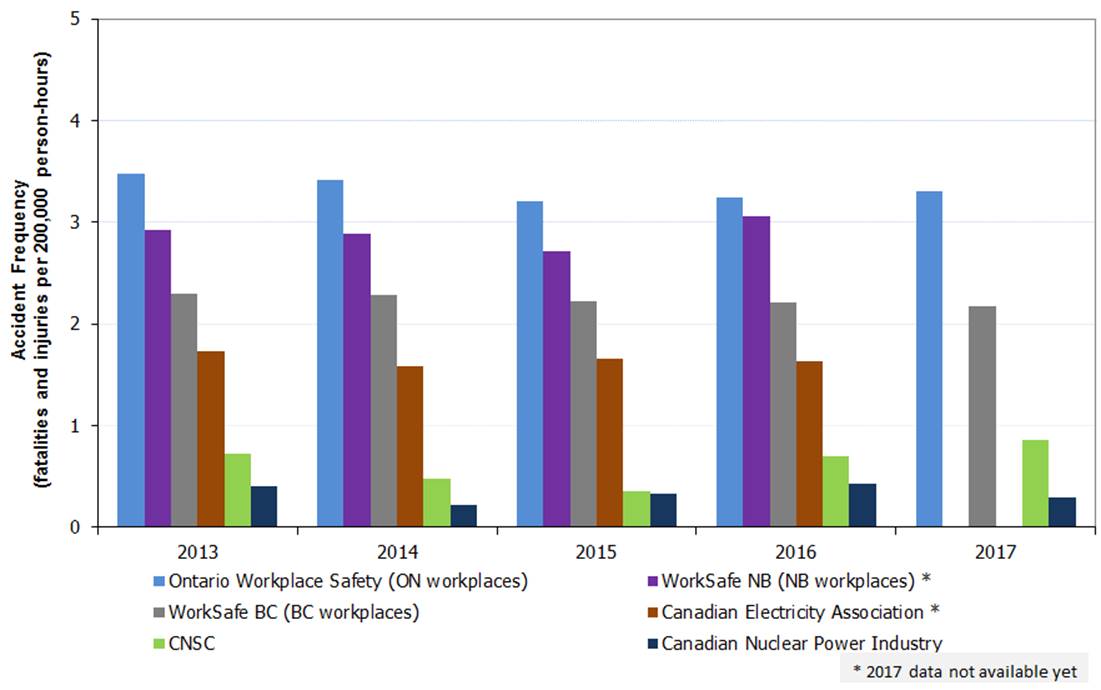

- The frequency and severity of non-radiological injuries to workers were very low.

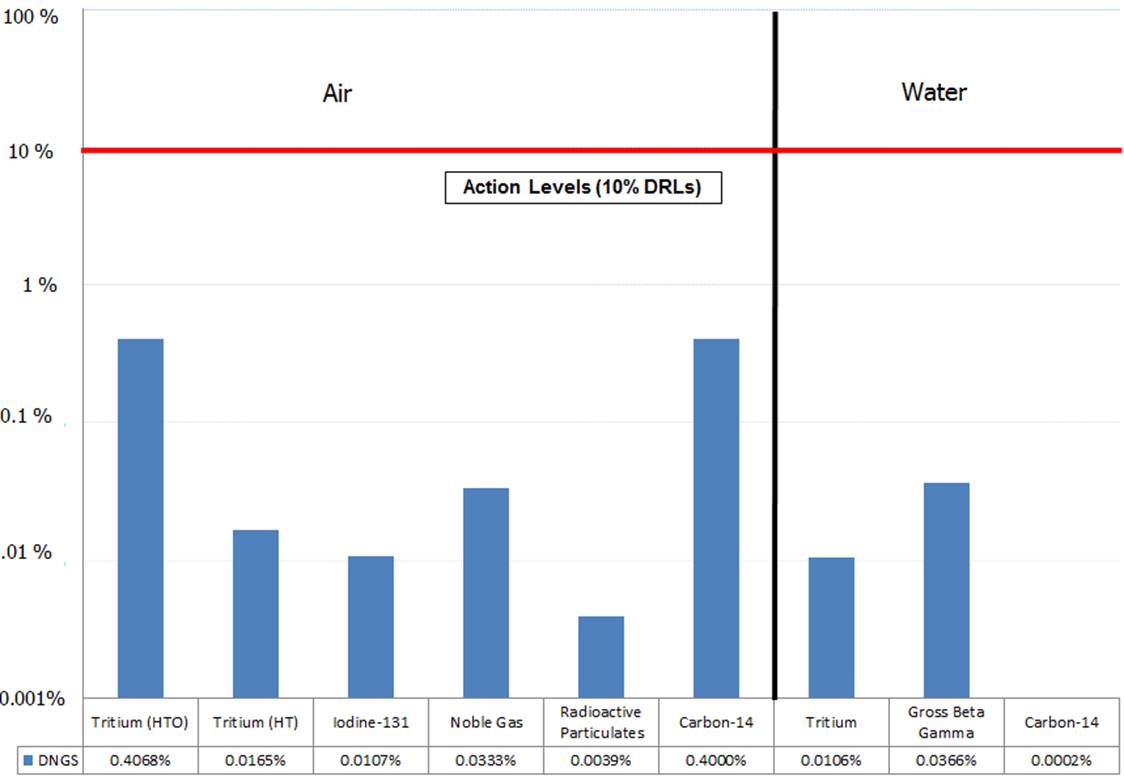

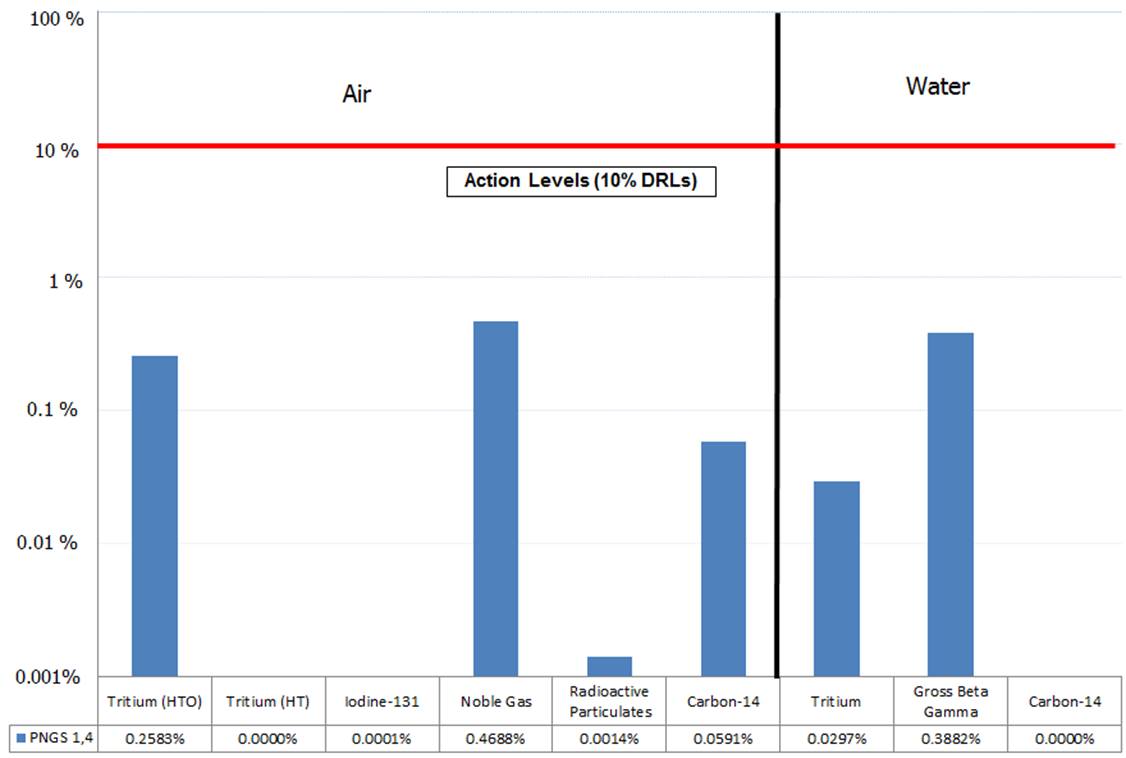

- No radiological releases into the environment from the NPPs and WMFs exceeded the regulatory limits.

- Licensees met the applicable requirements of Canada’s international obligations; the safeguard inspection results were acceptable to the IAEA.

CNSC staff assessments of the SCAs for the NPPs and WMFs are summarized in the ratings in the following tables. The rating categories used by CNSC staff in these assessments are:

- FS

- fully satisfactory

- SA

- satisfactory

- BE

- below expectations

- UA

- unacceptable

| Safety and control area | Bruce A | Bruce B | DNGS | PNGS | Point Lepreau | Gentilly-2 |

|---|---|---|---|---|---|---|

| Management system | SA | SA | SA | SA | SA | SA |

| Human performance management | SA | SA | SA | SA | SA | SA |

| Operating performance | FS | FS | FS | FS | SA | SA |

| Safety analysis | FS | FS | FS | FS | FS | SA |

| Physical design | SA | SA | SA | SA | SA | SA |

| Fitness for service | SA | SA | SA | SA | SA | SA |

| Radiation protection | FS | FS | SA | SA | SA | SA |

| Conventional health and safety | FS | SA | FS | FS | FS | SA |

| Environmental protection | SA | SA | SA | SA | SA | SA |

| Emergency management and fire protection | SA | SA | SA | SA | SA | SA |

| Waste management | FS | FS | FS | FS | SA | SA |

| Security | SA | SA | SA | SA | SA | SA |

| Safeguards and non-proliferation | SA | SA | SA | SA | SA | SA |

| Packaging and transport | SA | SA | SA | SA | SA | SA |

| Overall rating | FS | SA | FS | FS | SA | SA |

| Safety and control area | DWMF | PWMF | WWMF |

|---|---|---|---|

| Management system | SA | SA | SA |

| Human performance management | SA | SA | SA |

| Operating performance | FS | FS | FS |

| Safety analysis | FS | FS | FS |

| Physical design | SA | SA | SA |

| Fitness for service | SA | SA | SA |

| Radiation protection | SA | SA | SA |

| Conventional health and safety | FS | FS | FS |

| Environmental protection | SA | SA | SA |

| Emergency management and fire protection | SA | SA | SA |

| Waste management | SA | SA | SA |

| Security | SA | SA | SA |

| Safeguards and non-proliferation | SA | SA | SA |

| Packaging and transport | SA | SA | SA |

| Overall rating | SA | SA | SA |

1 Introduction

1.1 About this regulatory oversight report

The Regulatory Oversight Report for Canadian Nuclear Power Generating Sites: 2017 provides the Canadian Nuclear Safety Commission (CNSC) staff’s assessment of the overall safety performance of Canadian nuclear power plants (NPPs) and the adjacent waste management facilities (WMFs) for 2017.

Section 1 of the report provides introductory material that explains this report, the licensed facilities that are covered and the CNSC’s regulatory framework and practices.

Section 2 of the report provides background information that serves as context for the assessments. Although the assessments for each site are provided in section 3, some assessments of groups of licensees, where appropriate, appear in section 2. For example, section 2 compares safety performance data for multiple licensees. It also contains general assessments of all licensees as a whole in the area of security, since the information presented in section 3 for individual sites is limited.

Section 3 contains the individual assessments for each facility or site. In sections 3.1 and 3.2, the NPP and WMF on the same site are regulated under separate CNSC licences, and those subsections contain separate assessments of the NPP and WMF. This report uses headers to identify the information and assessments related to the two facilities. In sections 3.3 and 3.6, because the NPP and WMF on the same site are licensed together, they are assessed together. The safety assessments of the NPPs and WMFs are described in more detail in section 1.4.6.

Sections 2 and 3 are organized according to the CNSC’s safety and control area (SCA) framework. The SCA framework includes 14 SCAs grouped into three functional areas, and one additional area, as shown in table 1.

| Functional Area | SCA | # |

|---|---|---|

| Management | Management system | 1 |

| Human performance management | 2 | |

| Operating performance | 3 | |

| Facilities and equipment | Safety analysis | 4 |

| Physical design | 5 | |

| Fitness for service | 6 | |

| Core control processes | Radiation protection | 7 |

| Conventional health and safety | 8 | |

| Environmental protection | 9 | |

| Emergency management and fire protection | 10 | |

| Waste management | 11 | |

| Security | 12 | |

| Safeguards and non-proliferation | 13 | |

| Packaging and transport | 14 | |

| Other matters of regulatory interest | 15 | |

The safety assessments in this regulatory oversight report are done according to the licensing basis for each facility. The licensing basis is unique for each licensed facility. As such, statements related to compliance are in terms of the applicable regulatory requirements for the specific facility. The licensing basis is described in section 1.4.1.

The conclusions of this report are provided in section 4.

This report includes a list of references, a glossary and a list of the CNSC inspection reports that form the basis of many of the observations and conclusions in this report. In addition to the terms that are explained in the glossary, the reader should note the use of the terms “Indigenous peoples”, “public” and “general public”. Indigenous peoples include First Nation, Métis and Inuit communities. “General public” is meant to include all people and comprises two groups, Indigenous peoples and the public, each having distinct rights and interests.

1.2 Scope

The scope of the Regulatory Oversight Report for Canadian Nuclear Power Generating Sites: 2017 is significantly different than that of the Regulatory Oversight Report for Canadian Nuclear Power Plants: 2016 References 1 which only covered NPPs that were operating in Canada in 2016. Information about the Gentilly-2 facilities was not included as the facilities were permanently shut-down in 2012. Safety assessments of Gentilly-2 are included in this regulatory oversight report, since its status and regulatory oversight is similar to that of the WMFs covered in the report. General statements in the report that refer to “NPPs” apply to Gentilly-2, whereas the phrase “operating NPPs” is used in statements that do not apply to Gentilly-2.

Safety assessments of WMFs that are licensed separately from the NPPs but located at the same sites are also included in this regulatory oversight report. Although these WMFs have been covered in separate regulatory oversight reports in the past, there was no regulatory oversight report for them in 2016. However, the 2016 safety assessments of the PWMF and the WWMF were presented to the Commission at public hearings in April 2017.

Generally speaking, the information provided in this report is pertinent to 2017, and the status that is described is valid as of December 2017. Since Gentilly-2 and the WMFs were not covered by a regulatory oversight report for 2016, the descriptions of these facilities may contain more background information than those of the operating NPPs.

The term “UPDATE:” is used in the report to identify topics where more recent information (up to June 1, 2018) is included (e.g., descriptions of significant events or updates that were specifically requested by the Commission).

The detailed scope of the safety assessments in this report is covered by the set of specific areas that constitute each SCA. They are listed in section 2 at the beginning of each SCA section. Some specific areas do not apply to Gentilly-2 and the WMFs; where this is the case, those areas were not considered in the safety assessments for these facilities.

1.3 Nuclear facilities covered by this regulatory oversight report

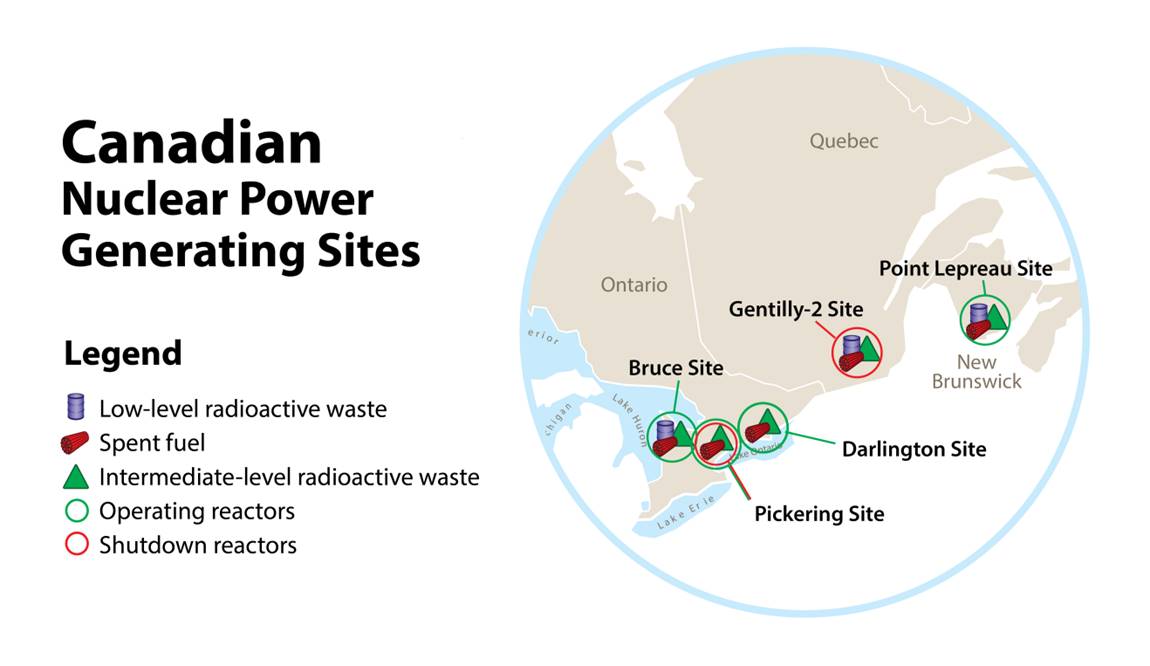

NPPs and WMFs are considered Class I facilities and are subject to the Class I Nuclear Facilities Regulations. Figure 1 shows the geographic location of the NPPs and WMFs covered in this report. All sites are located on traditional territories of Indigenous peoples in Canada.

1.3.1 Nuclear power generating sites in Canada

The Darlington site is located in Clarington, Ontario, and consists of the Darlington Nuclear Generating Station (DNGS) and the Darlington Waste Management Facility (DWMF). The DNGS and DWMF are licenced separately. See section 3.1 for details.

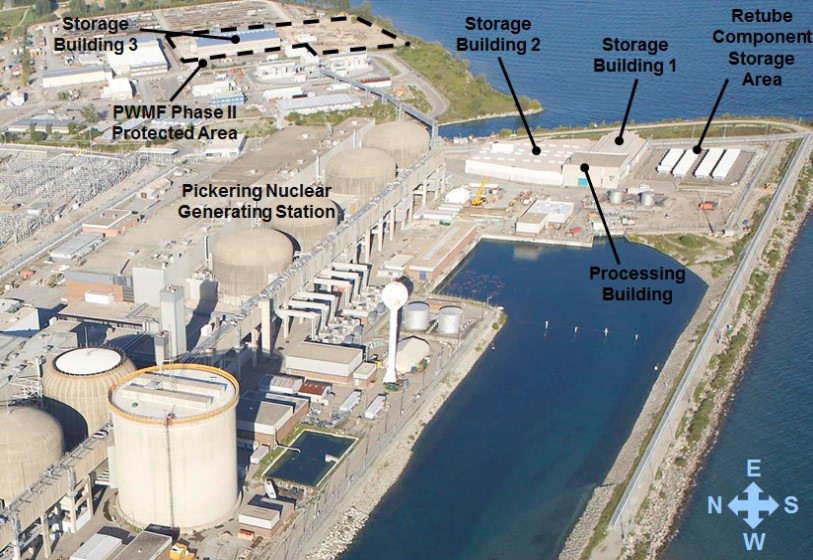

The Pickering site is located in Pickering, Ontario, and consists of the Pickering Nuclear Generating Station (PNGS) and the Pickering Waste Management Facility (PWMF). The PNGS and PWMF are licenced separately. See section 3.2 for details.

The Point Lepreau site is located at Point Lepreau, New Brunswick, and consists of the Point Lepreau Nuclear Generating Station (PLNGS) and the Solid Radioactive Waste Management Facility (SRWMF). The Point Lepreau NGS and SRWMF are licenced together. See section 3.3 for details.

The Bruce site is located in Tiverton, Ontario, and consists of the Bruce A and B NPPs, the Central Laundry and Maintenance Facility (CLMF), the Ontario Power Generation (OPG) Western Waste Management Facility (WWMF) and Radioactive Waste Operations Site-1 (RWOS-1), and the Canadian Nuclear Laboratory (CNL) Douglas Point Waste Facility (WF). The Bruce A and B NPPs and the CLMF are licenced together and operated by Bruce Power. The WWMF, RWOS-1 and Douglas Point WF are all licenced separately. See sections 3.4 and 3.5 for details. Note that the Douglas Point WF is not covered in this report; rather, it is covered in the Progress Update for CNL’s Prototype Waste Facilities, Whiteshell Laboratories and the Port Hope Area Initiative.

The Gentilly nuclear site is located in Bécancour, Quebec, and consists of CNL’s Gentilly-1 WF and Hydro-Québec’s Gentilly-2 facilities. The Gentilly-1 WF and Gentilly-2 facilities are licenced separately. See section 3.6 for details. Please note that the Gentilly-1 WF is not covered in this report; rather, it is covered in the Progress Update for CNL’s Prototype Waste Facilities, Whiteshell Laboratories and the Port Hope Area Initiative.

1.3.2 NPPs

NPPs are considered Class IA nuclear facilities, as defined in the Class I Nuclear Facilities Regulations.

Operating NPPs

Nineteen reactors continued to be operated in Canada throughout 2017, a figure unchanged from 2016. They are located in four NPPs, each with a power reactor operating licence (PROL) issued by the CNSC. They are located in two provinces (Ontario and New Brunswick) and are operated by three separate licensees (OPG, Bruce Power and NB Power). These NPPs range in size from one to eight power reactors, all of which are CANDU (CANada Deuterium Uranium) reactors.

Table 2 provides data for each operating NPP, including the generating capacity of the reactor units, the initial start-up date, the name of the licensee and the PROL expiry date. Additional information about the NPPs and licences is provided in section 3.

| NPP | Licensee | Location | State of reactor units | Gross capacity per unit (MWe) | Start-up1 | Licence expiry |

|---|---|---|---|---|---|---|

| DNGS | Ontario Power Generation Inc. | Clarington, ON | Four operating (including one undergoing refurbishment) | 935 | 1990 | November 30, 2025 |

| PNGS | Ontario Power Generation Inc. | Pickering, ON | Six operating, two defueled and in safe storage |

Units 1, 4: 542 Units 5–8: 540 |

Units 1, 4: 1971 Units 5–8: 1982 |

August 31, 2018 |

| PLNGS | New Brunswick Power Corp. | Point Lepreau, NB | One operating | 705 | 1982 | June 30, 2022 |

| Bruce A2 | Bruce Power Inc. | Tiverton, ON | Four operating | 831 | 1977 | May 31, 2020 |

| Bruce B2 | Bruce Power Inc. | Tiverton, ON | Four operating | 872 | 1984 | May 31, 2020 |

1 For the multi-unit NPPs, this indicates the start-up of the first reactor unit.

2 Bruce A and Bruce B are licensed as one multi-unit NPP consisting of eight operating reactor units.

Non-operating reactors and NPP

PNGS includes Units 2 and 3 which remain defueled and in safe storage. They are governed by the same PROL as the six operating units at Pickering.

The NPP at Gentilly-2 is shut down and is proceeding to decommissioning. It is also a CANDU design, and it is governed by a power reactor decommissioning licence.

New build

In 2012, the Commission issued a nuclear power reactor site licence (PRSL) to OPG for the new nuclear project at the Darlington site for a period of 10 years. The PRSL requires OPG to continue follow-up work on the environmental assessments (EAs) conducted in conjunction with the licence application. OPG carried out work in 2017 in the following areas:

- bank swallow monitoring and mitigation activities

- support for CNSC activities to engage stakeholders in developing policy for land use around nuclear generating stations

- development of a methodology that will help with siting of intake and diffuser structures in Lake Ontario

See appendix B for a description of the progress made in these activities and a description of the work anticipated for 2018.

1.3.3 WMFs

The WMFs that are assessed separately in this regulatory oversight report are licensed independently from the adjacent NPP. They include the Darlington, Pickering and Western WMFs (DWMF, PWMF and WWMF respectively). RWOS-1 is included in the assessment for WWMF. These facilities are defined as Class IB nuclear facilities in the Class I Nuclear Facilities Regulations. They are owned and operated by OPG.

Table 3 provides data for each WMF, including the initial start-up date, the name of the licensee, the licence expiry date and the type of waste managed at each facility – low-level waste (LLW), intermediate-level waste (ILW) or high-level waste (HLW). Additional information on the facilities and licences is provided in section 3.

As discussed in section 1.3.1, both the Point Lepreau and Gentilly-2 sites have WMFs that are further discussed in sections 3.3 and 3.6, respectively.

| Facility | Licensee | Location | Operation start | Licence expiry | Waste management |

|---|---|---|---|---|---|

| DWMF | OPG | Clarington, ON | 2008 | April 30, 2023 |

HLW from DNGS ILW from DNGS refurbishment |

| PWMF | OPG | Pickering, ON | 1996 | August 31, 2028 |

HLW from PNGS ILW from PNGS Units 1–4 refurbishment |

| WWMF | OPG | Tiverton, ON | 1974 | May 31, 2027 |

HLW from Bruce A and B NPPs ILW from Bruce Units 1 and 2 refurbishment L&ILW from DNGS, PNGS, and Bruce A and B NPP operations |

| RWOS-1 | OPG | Tiverton, ON | Mid-1960 | Indefinite | LLW and ILW from Douglas Point WMF and PNGS |

1.4 Regulatory framework and oversight

The CNSC is the federal government body that regulates the use of nuclear energy and materials to protect health, safety, security and the environment. It implements Canada’s international commitments on the peaceful use of nuclear energy and disseminates objective scientific, technical and regulatory information to the public relating to the points above. Licensees are responsible for operating their facilities safely and are required to implement programs that make adequate provisions for meeting legislative and regulatory requirements.

The CNSC regulates the nuclear sector in Canada, including NPPs and WMFs, through licensing, reporting, compliance verification and enforcement activities. For each NPP and WMF, CNSC staff perform inspections, surveillance and monitoring, and desktop reviews. The CNSC employs a rating methodology to assess collectively the results of these individual activities. The CNSC also conducts regulatory research and development (R&D) to support regulatory efforts (see appendix D). The CNSC uses a risk-informed regulatory approach that applies resources and regulatory oversight in a manner commensurate with the risk associated with the regulated facility and activity.

The CNSC’s regulatory programs for NPPs and WMFs involve the direct efforts of approximately 400 CNSC staff, including support from other members of the organization. This accounts for approximately 44% of the CNSC workforce. CNSC inspectors and other subject matter experts travel to NPPs and WMFs to conduct inspections and other regulatory activities (described further in section 1.4.4). At operating NPPs, the regulatory program also includes approximately 37 CNSC inspectors permanently located at those sites. The inspectors lead and participate in inspections, monitor safety performance and provide regulatory oversight from site offices.

The CNSC consults with Indigenous peoples to ensure the licensing decisions uphold the honour of the Crown and considers potential and established Aboriginal and treaty rights.

1.4.1 CNSC requirements

The licensing basis is defined in the CNSC information document titled Licensing Basis Objective and DefinitionReference 3. It comprises the following:

- the regulatory requirements set out in the applicable laws and regulations

- the conditions and safety and control measures described in the facility's or activity's licence and the documents directly referenced in that licence

- the safety and control measures described in the licence application and the documents needed to support that licence application

The licences for NPPs and WMFs contain a requirement for the licensees to operate in accordance with their licensing basis. The requirements in parts (ii) and (iii) of the licensing basis are unique to each licensed facility. They depend on the content of each licence, the licence applications and the applicant’s supporting documentation. CNSC regulations, including the Class I Nuclear Facilities Regulations, provide the requirements for the content of licence applications for NPPs and WMFs. In 2017, the CNSC published REGDOC-1.1.3, Licence Application Guide: Licence to Operate a Nuclear Power Plant to elaborate on the application requirements for operating NPPs. CNSC staff provide additional, tailored guidance to licensees that intend to renew their licences for NPPs and WMFs.

Licence applications for NPPs and WMFs cite CNSC regulatory documents, CSA Group standards, and other publications such as the applicant’s own documentation. When a licence is issued, CNSC staff develop a licence conditions handbook (LCH) (described further in section 1.4.2) to identify the specific requirements that apply to that licence. Appendix E lists all CNSC regulatory documents and CSA Group standards that have been identified as containing compliance verification criteria in the LCHs for the NPPs and WMFs covered by this regulatory oversight report.

Appendix E illustrates the vast number of CNSC regulatory documents and CSA Group standards that provides requirements relevant to the SCAs. It indicates the similarities and differences in the CNSC regulatory documents and CSA Group standards that apply to NPPs and WMFs. It indicates the differences in publications that apply to operating NPPs versus non-operating reactors such as Gentilly-2. It also indicates the significant number of newer CNSC regulatory documents and CSA Group standards that are being implemented by the licensees. Details about the implementation of these publications are provided under the relevant SCAs throughout this report.

Each licensee implements new CNSC regulatory documents and CSA Group standards in a staged, risk-informed manner that takes into consideration the timing of licence renewals, operational needs, and other concurrent changes. Although differences exist in applicable requirements between similar facilities at any given time, the requirements are nevertheless robust and comprehensive, and improved requirements are implemented in a measured and systematic way.

1.4.2 Licensing

The CNSC licensing process for NPPs and WMFs is comprehensive and covers all 14 SCAs.

The CNSC assesses licence applications to ensure that the proposed safety and control measures are technically and scientifically sound, all application requirements are met and the appropriate safety systems are in place to protect people and the environment. The CNSC assesses the adequacy of the proposed measures against the requirements in the regulations and criteria that have been provided to the applicant which are expected to become part of the licensing basis, if the licence is granted.

The licensing process has participation opportunities for the public and Indigenous peoples in Commission meetings and hearings. Commission hearings are often held in the community close to the site in question. All Commission proceedings are open to the general public and webcast live.

Each of the operating NPPs and WMFs described in this report has been granted a licence by the Commission. Typically, a waste facility operating licence is issued for a period of 10 years, and a power reactor operating licence is issued for 5 years. The CNSC is transitioning to longer licence periods for power reactor operating licences. For operating NPPs, this longer licence is issued in conjunction with the implementation of a comprehensive periodic safety review (PSR) process in preparation for the licence renewal.

The PSR is a comprehensive evaluation of the design, condition and operation of an NPP. CNSC REGDOC-2.3.3, Periodic Safety Reviews sets out the regulatory requirements for PSR implementation. As outlined in REGDOC-2.3.3, a PSR involves an assessment of the current state of the plant and plant performance to determine the extent to which the plant conforms to modern codes, standards and practices, and to identify any factors that would limit safe long-term operation. It gives the licensee a framework in which it can systematically identify practicable safety enhancements which are documented in an integrated implementation plan (IIP). The status of the PSR for each operating NPP is described in section 3.

A PSR is not a requirement for Gentilly-2 or the WMFs, because the associated hazards and requirements change relatively slowly, such that the regular licensing process and implementation of CNSC regulatory documents and CSA Group standards are sufficient to ensure safe long-term operation.

The NPP and WMF licences are relatively similar and contain standardized licence conditions that are organized by SCA. For example, under the radiation protection SCA, licences contain a condition that requires the licensee to implement and maintain a radiation protection program. The detailed compliance verification criteria for the radiation protection program are found in the LCH for the facility written by CNSC staff. LCHs are consistent with the licensing basis for the facility and establish the basis for the CNSC’s compliance verification program during the licence period.

When licensees implement new CNSC regulatory documents and CSA Group standards, the implementation plans are typically recorded in the LCH (i.e., the LCH will indicate the date on which CNSC staff will begin assessing compliance with the new or revised requirements).

In 2017, CNSC staff continued to standardize LCHs for NPPs and WMFs. This involved gradually adopting and adapting templates, generic text and common guidance for writing and revising LCHs that apply to all CNSC licences with LCHs. Revisions to the LCHs relevant to this report are summarized in appendix F.

Fisheries Act authorizations

In addition to CNSC licences, this regulatory oversight report also describes developments related to Fisheries Act authorizations, such as the preparation of applications and resulting decisions by Fisheries and Oceans Canada. The Fisheries Act requires the establishment of offsets to compensate for any residual harm caused to fish and fish habitats after mitigation measures have been put in place. The CNSC has a memorandum of understanding with Fisheries and Oceans Canada, whereby CNSC staff are responsible for monitoring activities and verifying compliance for Fisheries Act authorizations. The Minister of Fisheries and Oceans Canada is responsible for enforcing the authorizations in the event of non-compliance.

1.4.3 Reporting

Licensees are required to provide various reports and notices to the CNSC under CNSC regulations. LCHs clarify the CNSC’s expectations for these requirements.

In addition to the reporting requirements in the regulations, a condition in the licences of NPP licensees requires that they report to the CNSC in accordance with REGDOC‑3.1.1, Reporting Requirements for Nuclear Power Plants. REGDOC-3.1.1 requires licensees to submit quarterly and annual reports on various subjects (e.g., quarterly reports on the safety performance indicators) and it provides detailed requirements concerning the submission of other important reports (e.g., updates to the final safety analysis report, proposed decommissioning plan, annual environmental protection report). REGDOC-3.1.1 also requires licensees to report to the CNSC on any unplanned situations and events. These reports are posted by the licensees on their respective websites. The requirements in REGDOC-3.1.1 have been adjusted for Gentilly-2 based on its current state and the associated risks.

During 2017, NPP licensees reported to CNSC staff on 256 events and submitted 90 scheduled reports. Three of these events were presented to the Commission as event initial reports (EIRs); they are described in the relevant parts of section 3. WMF licensees submitted 13 reports to CNSC staff for reportable events under the General Nuclear Safety and Control Regulations that occurred at DWMF, PWMF and WWMF. No EIRs related to WMFs were presented to the Commission in 2017. The NPP EIRs and WMF reportable events are discussed in section 3. None of the events were above level 0 on the International Nuclear and Radiological Event Scale.

Note that the CNSC published REGDOC-3.1.2, Reporting Requirements for Non-Power Reactor Class I Facilities and Uranium Mines and Mills in January 2018. Beginning in 2019, WMF licensees will report to the CNSC in accordance with REGDOC-3.1.2.

1.4.4 Compliance program

The safety assessments presented in this report are based on the results of activities planned through the CNSC compliance verification program (CVP). In 2017, these activities included inspections supported by subject matter experts, desktop reviews by a wide range of technical specialists, and surveillance and monitoring conducted by CNSC inspectors. These activities were performed through a combination of document reviews, workplace observations and worker interviews. All compliance verification activities were fully documented.

Tables 4, 5 and 6 demonstrate the CVP effort by CNSC staff for each NPP and WMF. CNSC staff made approximately 16,000 person-days of effort conducting inspections, event reviews and other compliance activities in 2017, which is comparable to the effort made in 2016.

| Compliance activities effort | DNGS | PNGS | PLNGS | Bruce A and B | Gentilly-2 | Industry total |

|---|---|---|---|---|---|---|

| Inspections | 1,422 | 1,764 | 981 | 1,716 | 98 | 5,981 |

| Event reviews | 120 | 130 | 70 | 184 | 8 | 512 |

| Other activities* | 2,160 | 2,602 | 1,466 | 2,970 | 139 | 9,339 |

| Total effort | 3,702 | 4,497 | 2517 | 4,871 | 245 | 15,832 |

| DWMF | PWMF | WWMF | Industry total | |

|---|---|---|---|---|

| Inspections | 3 | 3 | 3 | 9 |

| Compliance activities effort | DWMF | PWMF | WWMF | Industry total |

|---|---|---|---|---|

| Event reviews | 75 | 209 | 258 | 542 |

| Other activities* | 161 | 94 | 227 | 482 |

| Total effort | 236 | 303 | 485 | 1,024 |

*Includes verification activities, such as surveillance and monitoring, and desktop reviews of licensee-submitted documents and reports (other than event reports)

The five-year trend in compliance activities is given in appendix G.

The goal is to ensure that the CVP for NPPs and WMFs is always timely, risk-informed, performance-based and responsive to developments. At its foundation, the CVP consists of a collection of compliance verification activities that cover the 14 SCAs conducted with varying frequency over a rolling five-year period. This baseline is the minimum set of activities needed to systematically and comprehensively determine whether licensees are complying with the safety and control measures in their licensing bases. Individual inspections typically verify compliance with requirements across multiple specific areas and SCAs.

For each NPP, between 80 and 100 applicable compliance verification activities are selected from the baseline for the year’s compliance plan. Additional reactive compliance verification activities for NPPs and WMFs are added as needed. These focus on site-specific matters and known or potential licensee challenges. The annual plans are then validated by CNSC subject matter experts and licensing staff using a risk-informed approach that considers the status, performance history, conditions and challenges of each facility to ensure appropriate regulatory oversight and safety performance evaluations. Additional compliance verification activities for NPPs and WMFs may be added as necessary during the year, as new licensee challenges emerge.

The CVP for NPPs includes reviews of safety performance indicators submitted quarterly to the CNSC. Data for some of the safety performance indicators submitted are reproduced in this report. There are no regulatory limits or thresholds associated with this data. However, CNSC staff monitor them, watching for trends over time and deviations from the data typically provided by other licensees with similar operations or facilities. Trends develop relatively slowly over time. The differences between licensees are relatively small since NPP licensees tend to have mature programs for the SCAs that are based on similar or identical requirements.

Any unfavourable trend or comparison is followed by increased regulatory scrutiny. Depending on the safety significance of the trend or deviation, increased regulatory scrutiny can range from increased surveillance and monitoring, to increased focus during field inspections, to adjusted timing and/or scope of a baseline inspection, focused desktop review or reactive inspection.

During 2015–16, the Commissioner of the Environment and Sustainable Development completed a performance audit of the CNSC’s oversight of the nuclear sector, reviewing the period of April 2013 to March 2015. Details were provided in the Regulatory Oversight Report for Canadian Nuclear Power Plants: 2016 References 1. The CNSC had implemented four of the audit’s five recommendations by September 30, 2016. Work to address the final recommendation – to improve the documentation on the site inspection planning process – was completed by March 31, 2017.

1.4.5 Enforcement

The CNSC uses a graduated enforcement approach to encourage and compel compliance and deter future non-compliance.

When a point of non-compliance is identified, CNSC staff determine the appropriate enforcement action based on the safety significance and other factors, such as whether the non-compliance is systemic or repeated. Each enforcement action is a discrete and independent response to a point of non-compliance.

Regulatory judgment is applied and multiple factors are taken into account to determine the most appropriate enforcement strategy for any given situation. If the initial enforcement action does not result in timely compliance, other enforcement actions are used.

Regulatory responses to non-compliance and enforcement measures include:

- notifying licensees

- issuing written notices

- increasing regulatory scrutiny

- making requests under subsection 12(2) the General Nuclear Safety and Control Regulations

- issuing administrative monetary penalties

- issuing orders

- taking licensing actions

- decertifying persons or equipment

- prosecuting

Enforcement actions may be applied independently or in combination with other actions.

1.4.6 Safety assessment ratings

This report presents safety performance ratings for each SCA at each NPP and WMF. The ratings are based on findings generated during CVP activities. The findings are categorized by appropriate SCA and specific area and assessed against a set of CNSC-developed performance objectives and criteria for the SCAs (see appendix A).

Since the CVP consists of a (typically five-year) rolling cycle of regulatory activities, not all specific areas are directly evaluated through inspections or desktop reviews each year. In rating specific areas, CNSC staff rely on inspections conducted in previous years supplemented by conclusions from other regulatory oversight conducted during 2017. This can include reviews of actions stemming from previous inspections and other developments, monitoring and surveillance at a site, and other interactions with the licensees.

The assessment presented in this report includes an overall rating for each NPP and WMF. It is a judgment of the overall safety performance at each facility. See appendix C for a comprehensive description of the CNSC rating methodology for NPPs and WMFs.

In generating the performance ratings for 2017, CNSC staff considered 1,547 findings for NPPs and WMFs. The vast majority of the findings (99.9%) were assessed as being either compliant, negligible or of low safety significance. In other words, they had a positive, insignificant or small negative impact on safety within the specific area. The remainder (fewer than 0.1%) had a significant negative effect in the context of assessing a specific area. These findings of medium safety significance are discussed in detail in section 3 of this report.

At the Bruce site, Bruce A and B are rated separately from WWMF because they are operated by different licensees. For the Darlington and Pickering sites, the NPP and WMF are rated separately because they are regulated by separate licences and have facility-specific regulatory requirements. However, they are discussed together in the same site subsection, as they have commonalities (the same licensee). The WMFs at Point Lepreau and Gentilly-2 are assessed together with their respective NPPs, as they are governed by the NPP licences and are subject to the same regulatory requirements (as was done in previous regulatory oversight reports).

The 2017 SCA ratings for the NPPs and WMFs are provided in section 2 by SCA and in section 3 by facility. In addition, section 3 provides the overall ratings for each NPP and WMF. For trending purposes, section 3 also cites the SCA ratings and overall ratings for the facilities in 2016. Gentilly-2 is an exception, as it was last rated in 2015. The 2016 ratings are explained and tabulated for all facilities in appendix C.

2 General and supporting information

This section provides general information organized by SCA that serves as background information for the assessments in section 3. It includes notes about the requirements for the assessments. Detailed information about the requirements is provided in appendix E.

2.1 Management system

This SCA covers the framework that establishes the processes and programs required to ensure that an organization achieves its safety objectives, continuously monitors its performance against those objectives and fosters a healthy safety culture.

| DNGS | DWMF | PNGS | PWMF | PLNGS | Bruce A | Bruce B | WWMF | Gentilly-2 |

|---|---|---|---|---|---|---|---|---|

| SA | SA | SA | SA | SA | SA | SA | SA | SA |

The management system encompasses the following specific areas:

- management system

- organization

- change management

- safety culture

- configuration management

- records management

- management of contractors

- business continuity

- performance assessment, improvement and management review

- problem identification and operating experience

Management system

The following publications contain regulatory requirements that were relevant in 2017:

- CSA Group standard N286-05, Management system requirements for nuclear power plants

- CSA Group standard N286-12, Management system requirements for nuclear facilities

Details on their applicability and implementation are provided in appendix E and section 3.

Licensee management systems encompass nuclear policy statements, descriptions of interfaces and supporting documentation that control and maintain the programs and processes that the management system comprises. The CNSC’s compliance verification activities gather objective evidence of the effectiveness of licensee management systems in accordance with regulatory requirements.

Organization

The organization of each licensee is defined in its management system documentation. Organizational structure, authorities, accountability and the responsibilities of positions are defined, including internal and external interfaces, how decisions are made and by whom. The CNSC’s compliance verification activities check that the organizational structures, roles and responsibilities are documented and current in the context of the processes reviewed during inspections and other oversight.

Change management

Licensees have approved processes to control changes to their organization, documentation, processes, programs, designs, drawings, structures, systems, components, equipment, materials and software. The processes ensure that changes are documented, justified and reviewed by stakeholders to assess the potential impact on safety. The level of approval is commensurate with the impact and complexity of the change.

Safety culture

Licensees periodically conduct safety culture self-assessments. Data is gathered by various methods, including surveys, interviews and focus groups. Bruce Power, OPG and NB Power have implemented safety-culture monitoring panels, in keeping with the guidance provided by the Nuclear Energy Institute. CNSC staff review licensees’ safety culture self-assessments and their results to confirm the adequacy of the licensees’ follow-up actions.

Configuration management

The licensees’ configuration management integrates management processes that ensure that the physical and operational configuration and documentation conform with the design requirements and licensing basis. These processes include the review of completion assurance before turning over structures, systems and components (SSCs) to operations.

Records management

Records management systems ensure that only approved and current documents are issued and used. Obsolete documents are withdrawn. Records are produced and reviewed for acceptance. Documents and records are available when they are needed. Records are protected and retained in accordance with the applicable regulatory requirements. CNSC staff base their assessment of the licensees’ implementation of the document and record control processes on many regulatory activities involving a variety of SCAs.

Management of contractors

CNSC staff assess licensees’ implementation of the supply chain programs that qualify contractors and manage contractual requirements and contractors’ work. Licensees’ management defines, plans and controls the business by establishing safety objectives that meet regulatory and licensee requirements. How well those objectives are achieved is measured and monitored, as are aspects that are assigned to contractors.

Business continuity

Licensees have measures in place to continue achieving their safety and business objectives in the event of disabling circumstances; these measures include contingency plans for maintaining or restoring critical safety and business functions.

Performance assessment, improvement and management review

Licensees continually assess and improve their management systems. Their senior management confirm their management system’s effectiveness in controlling safe operation through annual performance monitoring reviews. The input in these reviews includes audit and self-assessment results, the status of corrective actions and the key performance indicators used to maintain control of their processes and operate safely. From these reviews, actions are taken to resolve weaknesses identified in the management system.

Problem identification and operating experience

Licensees have corrective action programs to identify and resolve problems and take into account operating experience (OPEX). When problems arise, licensees take immediate action to limit the impact on their facilities. Problems are documented and reported to the appropriate levels of management to initiate the process of correcting their causes and to prevent the reoccurrence of significant events. The timeframes for controlling deficiencies and completing corrective actions are established.

For systemic or serious problems, licensees conduct root cause analyses. For lower safety-significance problems, the direct and apparent causes are determined. Licensees perform analyses to identify trends. Licensees also have an information-gathering and review process to identify and evaluate relevant OPEX to improve and implement actions that prevent the occurrence of problems.

2.2 Human performance management

This SCA covers the activities that enable effective human performance through the development and implementation of processes that ensure licensees have sufficient personnel in all relevant job areas. Personnel have the necessary knowledge, skills, procedures and tools to safely carry out their duties.

| DNGS | DWMF | PNGS | PWMF | PLNGS | Bruce A | Bruce B | WWMF | Gentilly-2 |

|---|---|---|---|---|---|---|---|---|

| SA | SA | SA | SA | SA | SA | SA | SA | SA |

Human performance management encompasses the following specific areas:

- human performance program

- personnel training

- personnel certification

- initial certification examinations and requalification tests

- work organization and job design

- fitness for duty

Human performance program

The human performance program is applied as a corporate requirement across the licensee organizations and implemented locally within the various departments, so it is applicable to both the NPPs and WMFs. Licensees use a human performance program to minimize errors and to support workers in completing their tasks effectively and safely.

Personnel training

The licensees use training systems based on the principles of a systematic approach to training (SAT).

The following publication contains regulatory requirements for NPPs and WMFs that were relevant in 2017:

- CNSC REGDOC-2.2.2, Personnel Training

Details on its applicability and implementation are provided in appendix E and section 6.2.

Personnel certification

This specific area applies to the NPPs but does not apply to the DWMF, PWMF or WWMF, because they have no certified personnel.

The following publication contains regulatory requirements that were relevant in 2017:

- CNSC RD-204, Certification of Persons Working at Nuclear Power Plants

Details on its applicability are provided in appendix E and section 3.

To become a certified worker, a candidate must successfully complete the training program and certification examinations. The CNSC certifies a candidate who meets the requirements in RD‑204 and who has demonstrated competence to safely perform the duties of the certified position. After they are certified by the CNSC, workers undergo continuing training and requalification testing to ensure that they maintain the knowledge and skills to safely perform their duties.

CNSC requires NPP licensees to have certified shift supervisors, reactor operators and health physicists. Due to the design of Bruce A, Bruce B and DNGS, the CNSC requires these licensees to also have certified Unit 0 operators (U0Os). The only certified persons working at Gentilly-2 are health physicists.

Table 7 shows the number of certified personnel who are available in the certified positions at each NPP as of December 31, 2017. The table also shows the minimum required number of personnel for each position, which is the minimum number of certified personnel who must be present at all times, multiplied by the total number of crews.

| Station | Reactor operator | Unit 0 operatorsa | Shift supervisorb | Health physicist | Total |

|---|---|---|---|---|---|

| Bruce A | |||||

| Actual | 51 | 21 | 19 | 5c | 96 |

| Minimum | 30 | 10 | 10 | 1 | 51 |

| Bruce B | |||||

| Actual | 58 | 26 | 17 | 5c | 106 |

| Minimum | 30 | 10 | 10 | 1 | 51 |

| DNGS | |||||

| Actual | 58 | 18 | 30 | 3 | 109 |

| Minimum | 30 | 10 | 10 | 1 | 51 |

| PNGS 1, 4 | |||||

| Actual | 36 | 16 | 4d | 56 | |

| Minimum | 20 | 10 | 1 | 31 | |

| PNGS 5–8 | |||||

| Actual | 60 | 19 | 4d | 83 | |

| Minimum | 30 | 10 | 1 | 41 | |

| Point Lepreau NGS | |||||

| Actual | 12 | 7 | 2 | 21 | |

| Minimum | 6 | 6 | 1 | 13 | |

| Gentilly-2 | |||||

| Actual e | 3 | 3 | |||

| Minimum e | 1 | 1 | |||

Notes:

- There are no U0O positions at PNGS 1, 4, PNGS 5–8 or Point Lepreau NGS.

- At multi-unit NPPs, the number of shift supervisors is the total of certified shift managers plus certified control room shift supervisors.

- Five health physicists are certified for both Bruce A and Bruce B.

- Four health physicists are certified for both PNGS 1, 4 and PNGS 5–8.

- There are no reactor operators, U0Os or shift supervisors at Gentilly-2.

Initial certification examinations and requalification tests

This specific area applies to the operating NPPs, but does not apply to the DWMF, PWMF or WWMF. As part of the personnel certification program to become certified workers, candidates are required to complete initial certification examinations. Workers who are certified are required to complete requalification tests as part of the requirements to renew their certification. CNSC staff administer the initial certification examinations and requalification tests for health physicists. The licensees are responsible for administering the certification examinations and requalification tests for all other certified staff. As noted above, health physicists are the only certified staff working at Gentilly-2. Since CNSC administers the initial examinations and requalification tests for them, this specific area does not apply to Hydro-Québec.

The following publication contains regulatory requirements that were relevant in 2017.

- CNSC RD-204, Certification of Persons Working at Nuclear Power Plants

Details on its applicability are provided in appendix E.

Work organization and job design

This specific area applies to the NPPs but does not apply to the DWMF, PWMF or WWMF.

Under the General Nuclear Safety and Control Regulations, licensees are required to ensure the presence of a sufficient number of qualified workers to safely carry out all licensed activities. Furthermore, NPP licensees must maintain a minimum shift complement (MSC) at all times in accordance with their licences. The MSC is specific to each NPP and is influenced by the design of the facility, operating and emergency procedures, and organizational functions. NPP licensees determine their respective MSC by systematic analysis and demonstrate their adequacy in integrated validation exercises which CNSC staff review. The analyses and validation reports become part of the licensing basis for each NPP.

The CNSC requires NPP licensees to report MSC points of non-compliance to it, under CNSC REGDOC-3.1.1, Reporting Requirements for Nuclear Power Plants. A total of eight MSC points of non-compliance were reported by licensees in 2017. Of the eight events reported, four events were related to the availability and qualifications of full-time and voluntary fire fighters and emergency response personnel. Some of them are described in more detail in section 3. The NPP licensees took appropriate actions to ensure safety was maintained, including operating in “quiet mode”Footnote 1 and calling in additional personnel. CNSC staff did not identify any significant operation-related issues related to these points of non-compliance.

Fitness for duty

All NPP and WMF licensees have fitness for duty programs.

The following publications contain regulatory requirements that were relevant in 2017:

- CNSC RD-204, Certification of Persons Working at Nuclear Power Plants

- CNSC RD-363, Nuclear Security Officer Medical, Physical, and Psychological Fitness

Details on their applicability and implementation are provided in appendix E and section 3.

CNSC published REGDOC-2.2.4, Fitness for Duty Volume II: Managing Alcohol and Drug Use in November 2017. It sets out the requirements and guidance for managing the fitness for duty of workers who occupy safety-sensitive and safety-critical positions in relation to alcohol and drug use at all high-security sites. All licensees of high-security sites were asked to provide implementation plans early in 2018. CNSC staff were reviewing the implementation plans in the first half of 2018. Details on this implementation are provided in section 3.

UPDATE: CNSC staff were reviewing the implementation plans in the first half of 2018.

All NPP licensees have procedures that specify requirements concerning hours of work and processes for monitoring compliance with the limits to hours of work. REGDOC‑3.1.1, Reporting Requirements for Nuclear Power Plants requires NPP licensees to prepare a quarterly report on the points of non-compliance with hours of work limits for certified staff who perform safety-related tasks.

In the four quarterly reports submitted to the CNSC in 2017, NB Power reported no points of non-compliance with its hours of work procedure for certified staff, and OPG reported two for the DNGS and one for the PNGS. Bruce Power reported numerous instances of non-compliance with its hours of work procedure for certified staff. These points of non-compliance are discussed in section 3.4.2. There were no points of non-compliance with provincial hours of work limits at the DWMF, PWMF and WWMF in 2017.

To ensure regulatory clarity and consistency in this area, the Commission approved REGDOC‑2.2.4, Fitness for Duty, Volume I: Managing Worker Fatigue for publication in March 2017. The NPP and WMF licensees submitted implementation plans and timelines to the CNSC. Details on its implementation are provided in section 3.

2.3 Operating performance

This SCA includes an overall review of the conduct of licensed activities and the activities that enable effective operating performance.

CNSC staff evaluate licensees’ operating performance by conducting various compliance verification activities which include reviewing quarterly operational reports, reviewing the reports and follow-up actions associated with reportable events, conducting baseline and focused inspections and follow-up on licensee’s responses to inspection findings.

| DNGS | DWMF | PNGS | PWMF | PLNGS | Bruce A | Bruce B | WWMF | Gentilly-2 |

|---|---|---|---|---|---|---|---|---|

| FS | FS | FS | FS | SA | FS | FS | FS | SA |

Operating performance encompasses the following specific areas:

- conduct of licensed activity

- procedures

- reporting and trending

- outage management performance

- safe operating envelope

- severe accident management and recovery

- accident management and recovery

Conduct of licensed activity

Operating policies and principles for NPPs and WMFs set out specific requirements to meet the design basis of the facility for safe operation. During onsite inspections, CNSC staff verify that safe work practices are being followed and they review licensee record systems to confirm that corrective actions are identified and tracked.

CNSC REGDOC-3.1.1, Reporting Requirements for Nuclear Power Plants requires operating NPP licensees to report serious process failures to the CNSC. CNSC staff have determined that there were no serious process failures at the NPPs in 2017. CNSC REGDOC-3.1.1 also requires operating NPP licensees to report on performance indicator “number of unplanned transients” to the CNSC. This performance indicator shows the unplanned reactor power transients due to all sources while the reactor was not in a guaranteed shutdown state (GSS).

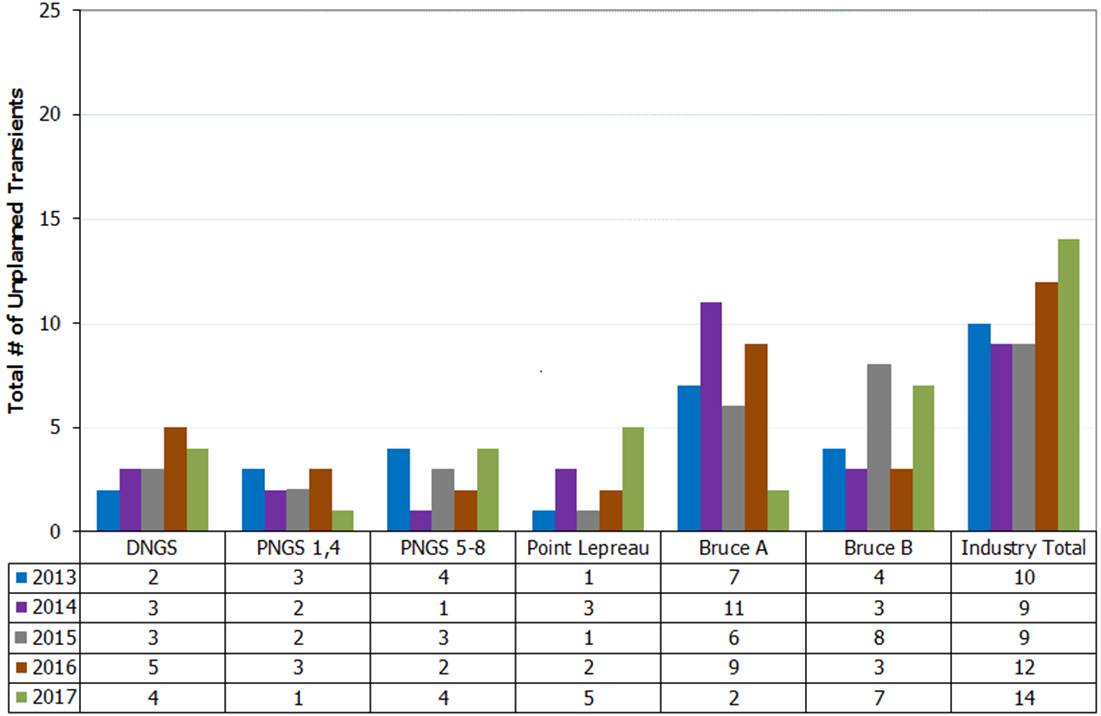

Unexpected reactor power reductions (or transients) can indicate problems within a plant and place unnecessary strain on its systems. Table 8 summarizes the number of unplanned reactor power transients at NPPs caused by stepbacks, setbacks and reactor trips where the trip resulted in a reactor shutdown. Stepbacks and setbacks are gradual power changes intended to eliminate potential risks to plant operations.

In 2017, all unplanned transients were properly controlled and adequately managed by the reactor control systems. They are discussed further in sections 3.1.3, 3.2.3, 3.3.3, and 3.4.3.

| NPP | Number of operating reactors | Number of hours of operation | Un-planned reactor trips1 | Step backs | Set backs | Total unplanned transients2 | Number of trips per 7,000 operating hours |

|---|---|---|---|---|---|---|---|

| DNGS | 4 | 23,846 | 1 | 1 | 2 | 4 | 0.29 |

| PNGS 1, 4 | 2 | 13,301 | 1 | n/a 3 | 0 | 1 | 0.53 |

| PNGS 5–8 | 4 | 29,825 | 0 | 0 | 4 | 4 | 0.00 |

| Point Lepreau | 1 | 7,928 | 0 | 0 | 5 | 5 4 | 0.00 |

| Bruce A | 4 | 32,965 | 2 | 0 | 0 | 2 | 0.42 |

| Bruce B | 4 | 30,871 | 0 | 1 | 6 | 7 | 0.00 |

| Industry total | 19 | 138,736 | 4 | 2 | 17 | 23 | 0.20 |

Notes:

- This includes automatic reactor trips only; it does not include manual reactor trips or trips during commissioning testing.

- Unplanned transients consist of unplanned reactor trips, stepbacks and setbacks.

- Stepbacks are not implemented at PNGS 1, 4.

- There were not five distinct events; see section 3.3.3.

Figure 2 shows the total number of unplanned transients from 2013 to 2017 for both individual operating NPPs and the operating NPPs as a whole (referred to as the industry total). The number of unplanned transients in 2017 was comparable to the numbers in previous years and was acceptable to CNSC staff.

Figure 2 - Text version

| DNGS | PNGS 1,4 | PNGS 5-8 | Point Lepreau | Bruce A | Bruce B | Industry Total | |

|---|---|---|---|---|---|---|---|

| 2013 | 2 | 3 | 4 | 1 | 7 | 4 | 10 |

| 2014 | 3 | 2 | 1 | 3 | 11 | 3 | 9 |

| 2015 | 3 | 2 | 3 | 1 | 6 | 8 | 9 |

| 2016 | 5 | 3 | 2 | 2 | 9 | 3 | 12 |

| 2017 | 4 | 1 | 4 | 5 | 2 | 7 | 14 |

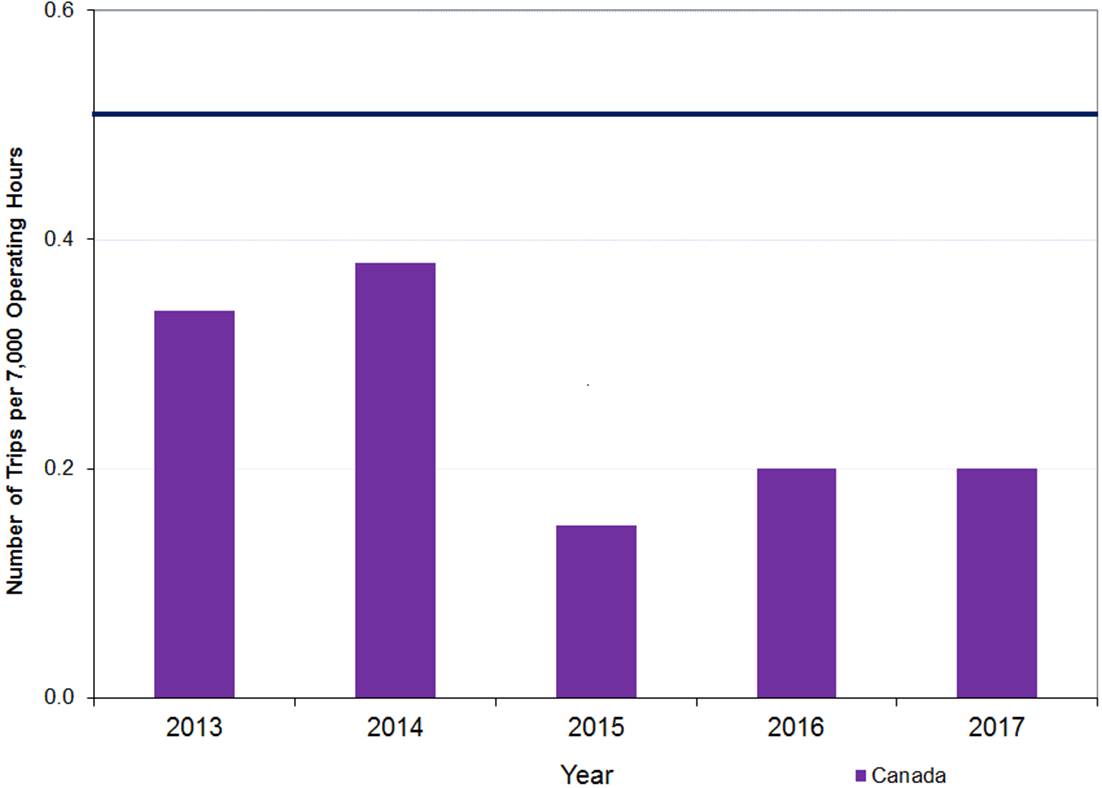

Figure 3 compares the number of unplanned reactor trips for Canada’s operating NPPs per 7,000 hours of operation, a measure used by the World Association of Nuclear Operators (WANO). In 2016, WANO began reporting the overall percentage of reactors that met the WANO targets. WANO targets for overall industry performance for specific reactor types include the following:

- conduct of licensed activity

- 1.0 unplanned total scram per 7,000 hours critical for pressurized heavy water reactors

Although the WANO target for pressurized heavy water reactors is a more appropriate benchmark for the CANDU reactors at Canadian NPPs, figure 3 indicates a more challenging target (0.5) for pressurized water reactors. The following approximations are derived from representative data in the 2016 WANO performance indicator publication (WANO data for 2017 is not yet available). They can be used to compare Canadian NPP performance with reactor performance worldwide:

- Only 64% of pressurized water reactors worldwide met the WANO industry target of 0.5 unplanned total scrams per 7,000 hours critical

- Only 58% of pressurized heavy water reactors worldwide met the WANO industry target of 1.0 unplanned total scram per 7,000 hours critical

Figure 3 indicates that collectively, Canadian NPPs came well within those targets in both 2016 and 2017.

Figure 3 - Text version

| 2013 | 2014 | 2015 | 2016 | 2017 | |

|---|---|---|---|---|---|

| Canada | 0.34 | 0.38 | 0.15 | 0.20 | 0.20 |

Procedures

All NPPs and WMFs have processes in place to ensure that procedures are developed and changes to them are managed consistently to support the safe operation and maintenance of each facility.

Reporting and trending

Sections 29 and 30 of the General Nuclear Safety and Control Regulations outline specific scenarios in which a licensee must file a report to the CNSC. For every reportable event, the licensee must file a full report that provides details of the event, including the effects on the environment, the health and safety of persons, the maintenance of security that have resulted or may result from the situation and the actions the licensee has taken or proposes to take with respect to the reportable event.

The following publications elaborate the regulatory requirements for reporting for NPPs:

- CNSC REGDOC-3.1.1, Reporting Requirements for Nuclear Power Plants

- CNSC REGDOC-3.1.1, Reporting Requirements for Nuclear Power Plants, Version 2

Details on their applicability and implementation are provided in appendix E and section 3. Additional requirements and guidance are specified for event, quarterly and annual reports. REGDOC-3.1.1 is described further in section 1.4.3.

CNSC staff found that the licensees’ reporting and trending met regulatory requirements in 2017.

For the WMFs, reporting requirements are found in the applicable regulations, such as the General Nuclear Safety and Control Regulations, and the operating licences. For example, each waste facility operating licence (WFOL) contains a licence condition on reporting requirements that covers the content and submission deadline of quarterly and annual reports.

CNSC staff follow up on all reportable events of NPPs and WMFs in a graded approach, based on the risk significance of the event, including the corrective actions that are taken. CNSC staff inform the Commission of significant reportable events through either event initial reports (EIRs) or regular status updates. The most significant events reported in 2017 relating to the NPPs and WMFs are discussed in this report.

Outage management performance

This specific area applies to the operating NPPs but does not apply to the DWMF, PWMF, WWMF or Gentilly-2.

CNSC staff conduct inspections during NPP outages to confirm that regulatory requirements continue to be met and that work is executed safely. CNSC staff monitor the level of performance and achievement of objectives during planned maintenance outages. CNSC staff also confirm that forced outages and outage extensions are managed safely and in accordance with the applicable regulatory requirements. CNSC staff inform the Commission of unplanned outages resulting from reactor trips and their outcomes via EIRs and status reports on NPPs.

Safe operating envelope

This specific area applies to the operating NPPs, but does not apply to the DWMF, PWMF, WWMF or Gentilly-2.

The following publication contains regulatory requirements that were relevant to operating NPPs in 2017:

- CSA Group standard N290.15-10, Requirements for the safe operating envelope of nuclear power plants

Each operating NPP’s adherence to its safe operating envelopes (SOE) ensures that each reactor operates in an analyzed state, thereby ensuring adequate safety at all times.

Severe accident management and recovery

The licensees have established roles and responsibilities within their organizations to manage severe accidents at their sites, should they occur. All NPP licensees have developed and implemented severe accident management guidelines (SAMGs). SAMGs include measures to prevent severe damage to the reactor core in the event of an accident, mitigate the consequences of an accident involving damage to the reactor core and achieve stable conditions in the long term.

Licensees have also developed emergency mitigating equipment guidelines (EMEG) to provide instructions for use and deployment of emergency mitigating equipment (EME). The purpose of EME is to provide additional water make-up and power-supply capabilities to cool the fuel, arrest accident progression and mitigate accident consequences for beyond-design-basis accidents, including severe accidents.

In 2017, licensees continued to update their existing SAMGs to incorporate lessons learned post-Fukushima, including the addition of guidelines and strategies to deal with multi-unit events for multi-unit NPPs, and events in irradiated fuel bays and shutdown states.

The following publication was relevant in 2017:

- CNSC REGDOC 2.3.2, Accident Management: Severe Accident Management Programs for Nuclear Reactors (2013)

The 2013 version of REGDOC-2.3.2 provides guidance (but not requirements) for severe accident management. Details on its applicability and implementation are provided in appendix E and section 3. The CNSC published version 2 of REGDOC-2.3.2, Accident Management in 2015 which supersedes the 2013 version. It provides both regulatory requirements and guidance for managing all accidents, including severe accidents at reactor facilities. The CNSC asked the licensees of operating NPPs to submit their implementation plans. NB Power submitted its plan in 2017 (see section 3.3.3 for details).

Accident management and recovery

CNSC compliance verification activities ensure that up-to-date procedures are available to the operators and that those operators are trained in their use. NPP and WMF licensees have adequate procedures in place (e.g., abnormal incident manuals and emergency operating procedures for NPPs) to manage abnormal incidents as well as design-basis accidents. These procedures ensure that incidents are mitigated and the facility is returned to a safe and controlled state. They also prevent the abnormal incident from escalating further into a serious accident.

2.4 Safety analysis

This SCA pertains to maintaining the safety analysis that supports the overall safety case for each facility. Safety analysis is a systematic evaluation of the potential hazards associated with the conduct of a proposed activity or facility, and it considers the effectiveness of preventive measures and strategies in reducing the effects of such hazards.

For NPPs, safety analysis is primarily deterministic in demonstrating the effectiveness of the fundamental safety functions of “control, cool, and contain”. Risk contributors are considered by using probabilistic safety assessments (PSAs). Appropriate safety margins should be demonstrated to address uncertainties and limitations of safety analysis approaches.

| DNGS | DWMF | PNGS | PWMF | PLNGS | Bruce A | Bruce B | WWMF | Gentilly-2 |

|---|---|---|---|---|---|---|---|---|

| FS | FS | FS | FS | FS | FS | FS | FS | SA |

Safety analysis encompasses the following specific areas:

- deterministic safety analysis

- probabilistic safety assessment

- criticality safety

- severe accident analysis

- management of safety issues (including R&D programs)

The following publication contains regulatory requirements that were relevant to this SCA in 2017:

- CSA Group standard N286.7, Quality assurance of analytical, scientific, and design computer programs for nuclear power plants

Deterministic safety analysis

NPP and WMF licensees submit a safety analysis report for their facilities every five years at a minimum that effectively identifies facility hazards and items that are relied on to safely control or mitigate these hazards. It demonstrates the adequacy of the design of the facility.

The following publications contain regulatory requirements that were relevant in 2017:

- CNSC REGDOC-2.4.1, Deterministic Safety Analysis

- CSA Group standard N293, Fire protection for nuclear power plants (2007)

- CSA Group standard N293, Fire protection for nuclear power plants (2012)

- CSA Group standard N393, Fire protection for facilities that process, handle, or store nuclear substances (2013)

Details on their applicability and implementation are provided in appendix E and section 3.

The NPP licensees are undertaking a safety analysis improvement program linked to the ongoing staged implementation of REGDOC-2.4.1. One area of focus in 2017 was the deterministic safety analysis for common mode events (CMEs) which contains some new features for analyzing multi-unit CANDU reactors.

CNSC staff provide feedback to the NPP licensees on their ongoing safety analysis improvements. The existing licensees’ deterministic safety analyses remained adequate during the continued implementation of REGDOC-2.4.1 throughout 2017.

Impact of aging on the safety analysis for NPPs

The aging of a reactor affects certain characteristics of the heat transport system which can result in a gradual reduction of safety margins. Therefore, compensatory measures are implemented to mitigate the impact of aging when needed. The structures, system and components (SSCs) of a reactor are affected by aging simultaneously and to different degrees. As such, the overall safety case of an NPP needs to be periodically assessed and the existing safety margins quantified.

Important parameters related to the safety analysis of reactor aging are systematically monitored through an aging management program put in place by the licensee. The aging management program is supported by the licensee’s assessments of the existing safety margins as reactor conditions change due to aging. The goal of the assessments and aging management programs is to monitor, assess and mitigate the impact of heat-transport system aging on safety analyses and to demonstrate safe plant operation.

CNSC staff were satisfied with the licensees’ consideration of aging in their safety analyses in 2017.

Large-break loss-of-coolant accident: safety margin for NPPs

OPG, NB Power and Bruce Power have proposed using the composite analytical approach (CAA) to demonstrate that safety margins for large-break loss-of-coolant accidents (LBLOCAs) are greater than those evaluated using the traditional safety-analysis method that is based on a limit of operating envelope approach. (See the description in the specific area of management of safety issues below for further details.)

At the conceptual level, the proposed CAA methodology is consistent with the requirements set out in REGDOC-2.4.1. However, CNSC staff have determined that the methodology requires further validation and refinement before it can be accepted for regulatory application. A number of key activities have been identified that would lead CNSC staff to accept the CAA methodology. Overall, the industry continues to progress well with all identified activities.

Bruce Power submitted a work plan for CAA development in late 2016 to use the CAA methodology to quantitatively demonstrate that the LBLOCA safety margins were greater than predicted in the analysis for the Bruce B reactors. The work plan was reviewed in 2017 by CNSC staff. CNSC staff concluded that overall, the proposed work is acceptable. However, further clarification is required in some areas. While addressing CNSC staff’s review comments, Bruce Power plans to submit the results in a regulatory application of the CAA for an LBLOCA safety analysis of Bruce B reactors in mid-2019.

OPG continues to support industry efforts in the resolution of LBLOCA safety margins using the CAA as part of its long-term plan. Meanwhile, OPG had proposed an improvement to its current approach, a more realistic implementation of the limit of operating envelope (LOE) methodology to address the LBLOCA safety margin issue in the short term. In 2017, CNSC staff reviewed the proposed work and made certain recommendations in some areas.

UPDATE: OPG addressed some of the CNSC staff’s comments, and it plans to submit its updated LBLOCA safety analysis using the proposed and more realistic implementation of LOE methodology for the DNGS in March 2018 and for the PNGS in a subsequent phase. As mentioned above, OPG also continues to work with Bruce Power to further develop CAA methodology for regulatory application.

NB Power continues to cooperate with Bruce Power on the generic aspects of the CAA project and may consider a CAA-based analysis in the future.

While the development of advanced analytical methods such as CAA continues, CNSC staff have confirmed that all operating NPPs have sufficient LBLOCA safety margins for the most probable operating states. As a risk control measure, CNSC has put in place a set of interim criteria for the safety margins (in case of discoveries that could decrease margins further) until CAA is implemented in regulatory applications.

Fire Safety Analysis

The CNSC requires NPP and WMF licensees to complete and maintain comprehensive fire protection assessment reviews (e.g., CCR and Fire Hazard Analysis (FHA)). These reviews help ensure that each licensee is able to efficiently and effectively prevent, detect and mitigate the effects of a fire, and to protect the ability to safely shutdown in the event of a fire.

Probabilistic safety assessment